Improved topsheet contacting hydrous body tissues, and absorbent device using the topsheet

A topsheet, body technology, applied in the field of interception of exudates, absorbent devices, body contact surfaces or topsheets, which can solve the problems of user discomfort, pain and irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

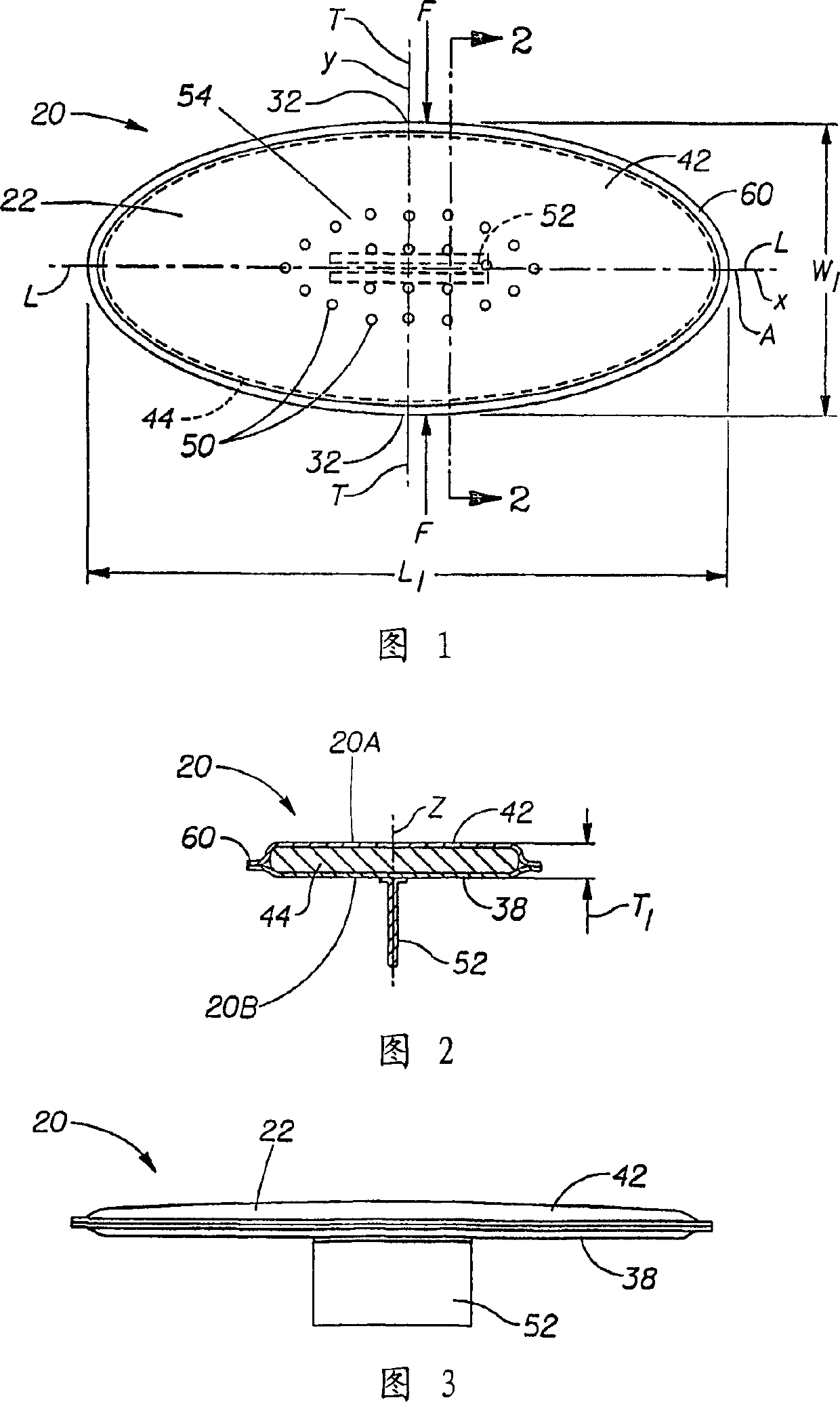

[0157] The product size is 91 mm x 46 mm, and the thickness is 5.0 mm.

[0158] The following materials are included in the product:

[0159] • A starch size bonded rayon topsheet basis basis of about 15 g / m2, similar to that used to wrap over sanitary tampons (especially TAMPAX tampons), sold by BBA Nonwoven, Green Bay, Wisconsin.

[0160] • The core material is a carded batt blended with 50% rayon and 50% blended cotton. 50% rayon is Sarille L rayon fiber, 50% cotton blend is a blend of cotton fiber and 0.03% lyomin finish, sold by Brannoc, North Devon, England.

[0161] ●The backsheet is a polybutylene succinate adipate film, colored with Ampacet 110361 sold by Showa High Polymer Co., Tokyo, Japan, and the product brand is BIONELLE 3001. The backsheet is joined to the topsheet by seams to form a peripheral seal.

[0162] The core is attached to the backsheet with two helical hot-melt adhesives, and the hot-melt adhesive is centered on both sides of the overall keel devic...

example 2

[0165] The product size is 91 mm x 46 mm, and the thickness is 6.0 mm.

[0166] The following materials are included in the product:

[0167] • Thermally bonded nonwoven fabric with a basis weight of 17 g / m2, manufactured by Vliesstoffwerke Christian Heinrich Sandler GmbH & Co. KG (Schwarzenbach / Saale, Germany) under the tradename Sawabond 4313. The topsheet is mechanically modified to improve its comfort as described in US Patent Application Serial No. 09 / 637,440 filed on August 11, 2000.

[0168] • The absorbent core structure comprises a nonwoven acquisition layer (Texel Inc., Quebec / Canada) having a basis weight of 60 grams per square meter. The acquisition layer consisted of 50% PET (Celenese #295, sold by Celenese AG (Summit, NJ / USA)) and 50% Rayon / CMC Alloy fibers (Accordis, Mobile, Alabama / USA, trial code 2014), non-woven acquisition layer Crosslinked by needle punching process with an airlaid absorbent core having a basis weight of 300 g / m2. The absorbent core cons...

example 3

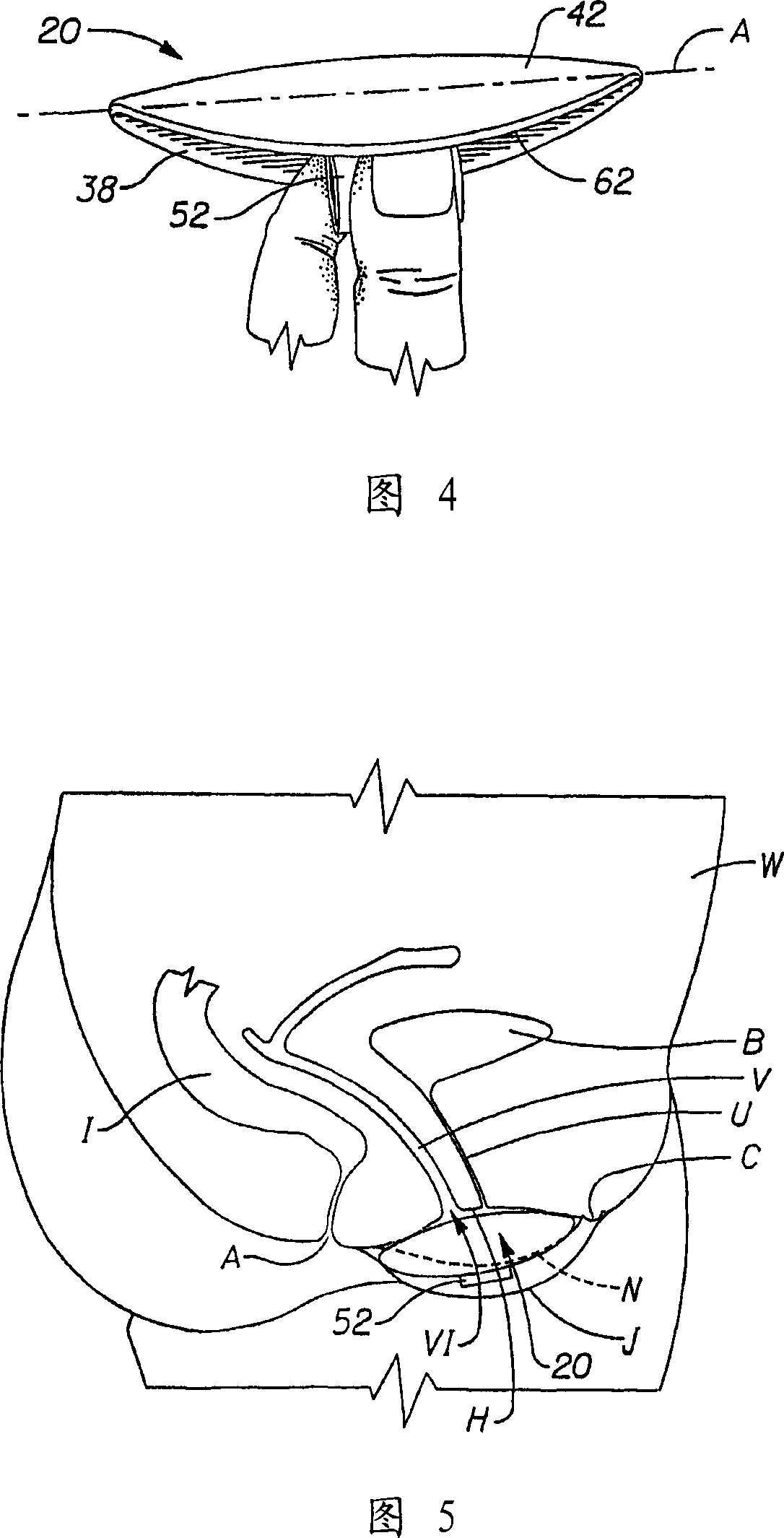

[0173] The product size is 91 mm x 46 mm, and the thickness is 6.0 mm. And include the same material and keel arrangement as Example 2. The softness and ability to conform to the labial vestibular structure of the overall product is enhanced by the use of a core slot structure instead of the core used in Example 2. It remains the same except for the following:

[0174] The softness of the entire product is due to the use of parallel (5 mm intervals) slots transverse to the machine direction (perpendicular to the length of the product) (each slot is 10 mm long and the next slot is 5 mm apart) Sexuality and the ability to conform to the labial-vestibular structures are enhanced. The slot extends from the top of the core to the bottom of the core and runs the full depth of the material. This alternative slot configuration allows for significantly less force required to bend the product when subjected to the V-bend test and the L-bend test, thereby facilitating insertion / applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com