Powder of royal jelly propolis and production technology

A production process and technology of royal jelly bee, applied in the field of royal jelly propolis powder and production process, can solve the problems of poor product uniformity, poor degreasing effect, poor binding force between royal jelly and propolis, etc. Stable quality and obvious health care effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

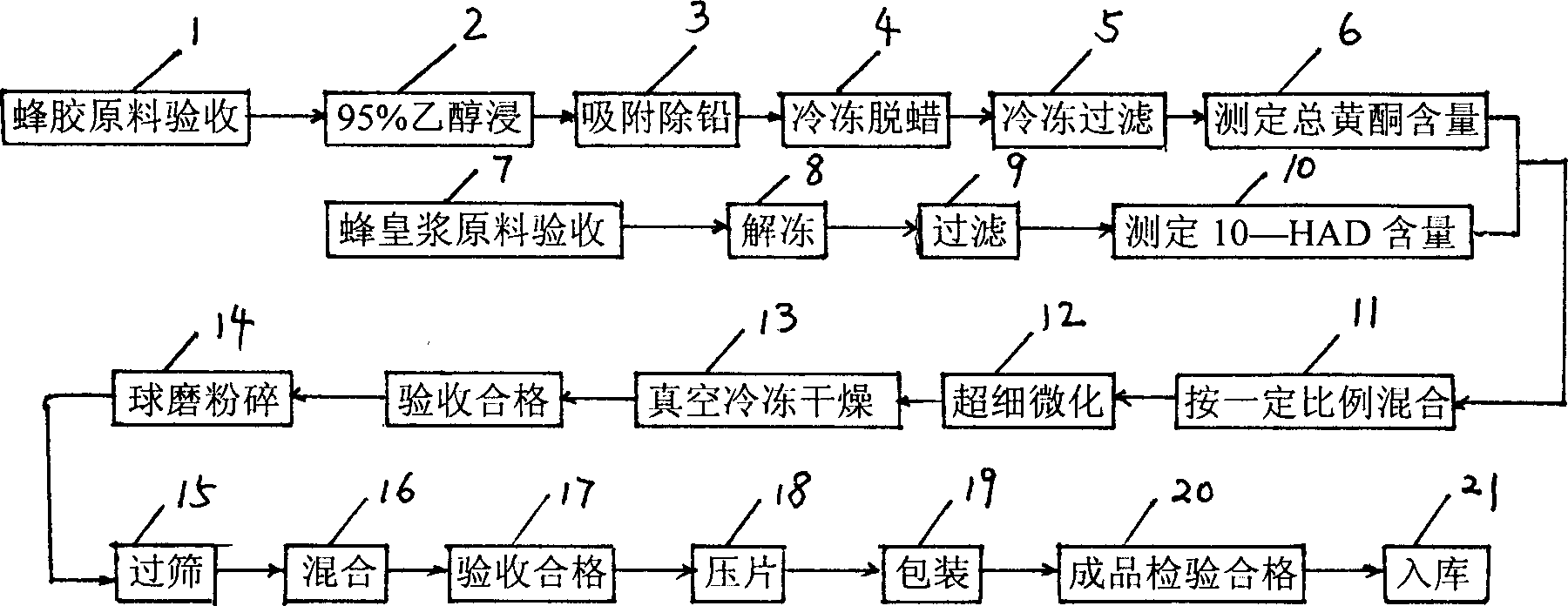

[0018] Embodiment one, such as figure 1 As shown, the present invention first carries out propolis raw material acceptance 1, takes propolis raw material, after passing the sensory inspection, takes a sample, measures glue content, total flavonoids, and carries out liquid phase fingerprint determination, then carries out the purification of propolis. 95% ethanol extraction 2, the propolis is crushed and then extracted with 95% ethanol to extract the supernatant. Adsorption lead removal 3, using the adsorption method, put the adsorbent into the material, and age it for one month to absorb heavy metals in the propolis liquid, including harmful substances such as lead. Freezing dewaxing 4, placing the propolis after adsorption and deleading in an environment below -10°C for more than 24 hours for dewaxing, and then freezing and filtering through a filter at the ambient temperature 5. The high-purity propolis extract is obtained, and the total flavonoid content is determined to m...

Embodiment 2

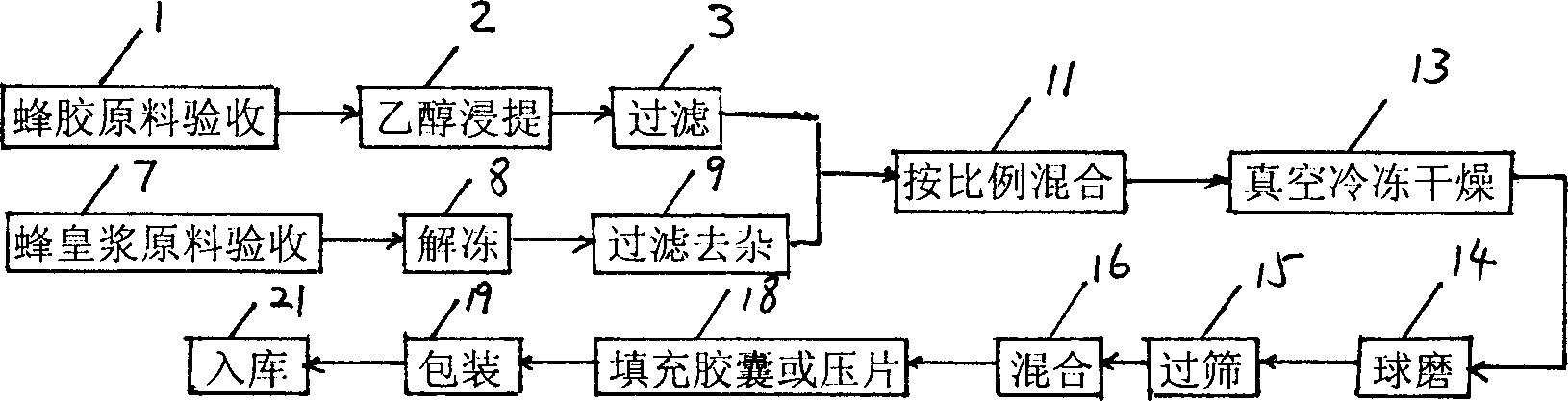

[0019] Embodiment two, see appendix figure 2 As shown, the propolis raw material acceptance 1 is carried out first, the propolis raw material is taken, after passing the sensory inspection, the sample is taken, the gum content and total flavonoids are determined, and the liquid phase fingerprint is determined, and then the propolis is purified. Ethanol extraction 2, the propolis is crushed and extracted with 95% ethanol to extract the supernatant. Adsorption filtration 3, using the method of adsorption, put the adsorbent into the material, and age it for one month to absorb heavy metals in the propolis liquid, including harmful substances such as lead. The royal jelly has also passed raw material inspection7, and after thawing8, it is filtered at room temperature9 to remove impurities. Mix royal jelly and propolis at a ratio of 90% to 10%11, then put the mixture into vacuum freeze-drying13, it is to freeze the mixture to below -30C, and carry out sublimation of water to ensu...

Embodiment 3

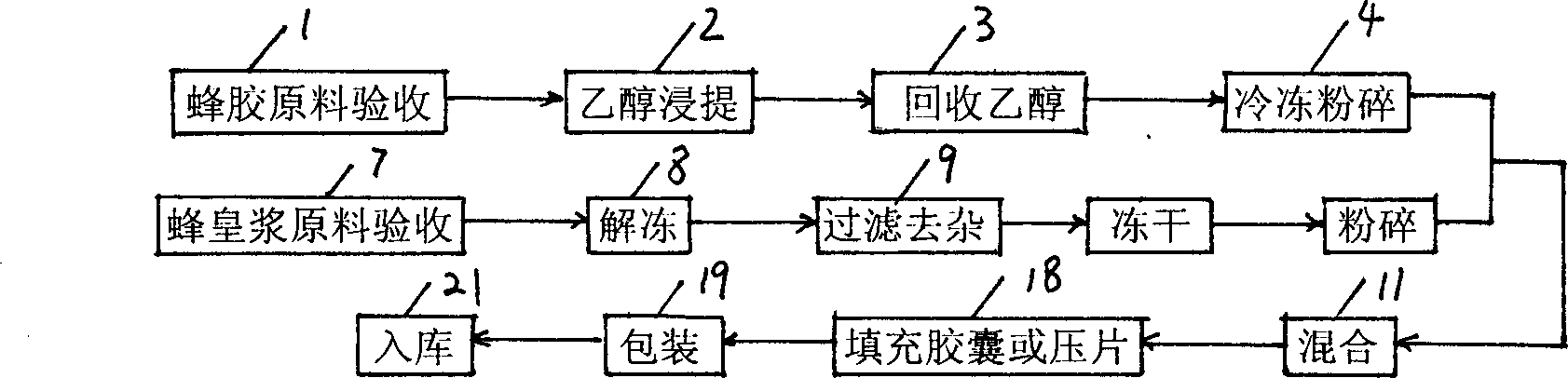

[0020] Embodiment three, see appendix image 3 As shown, the propolis raw material acceptance 1 is carried out first, and then the purification of propolis is carried out, that is, ethanol extraction 2 is carried out first, the supernatant is extracted, and then ethanol is recovered 3, and then frozen and crushed at low temperature 4; similarly, royal jelly is also processed Acceptance of raw materials 7, after thawing 8, filter at room temperature 9 to remove impurities, then freeze-dry and freeze crush, mix royal jelly and propolis at a ratio of 99% to 1% 11, so that royal jelly and propolis are fully and After evenly mixing 16, filling capsules or tablets 18, packaging 19, finished product inspection and storage 21.

[0021] The present invention adopts the whole process of royal jelly and propolis to be carried out basically at low temperature, which solves the problem of product inactivation during the process, ensures the quality of raw materials and products, achieves m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com