Method of judging residual film through optical measurement

A technology for optical measurement and measurement of light, which is applied in the direction of material analysis, color/spectral characteristic measurement, and electrical measurement through optical means, and can solve problems such as difficult states and classifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

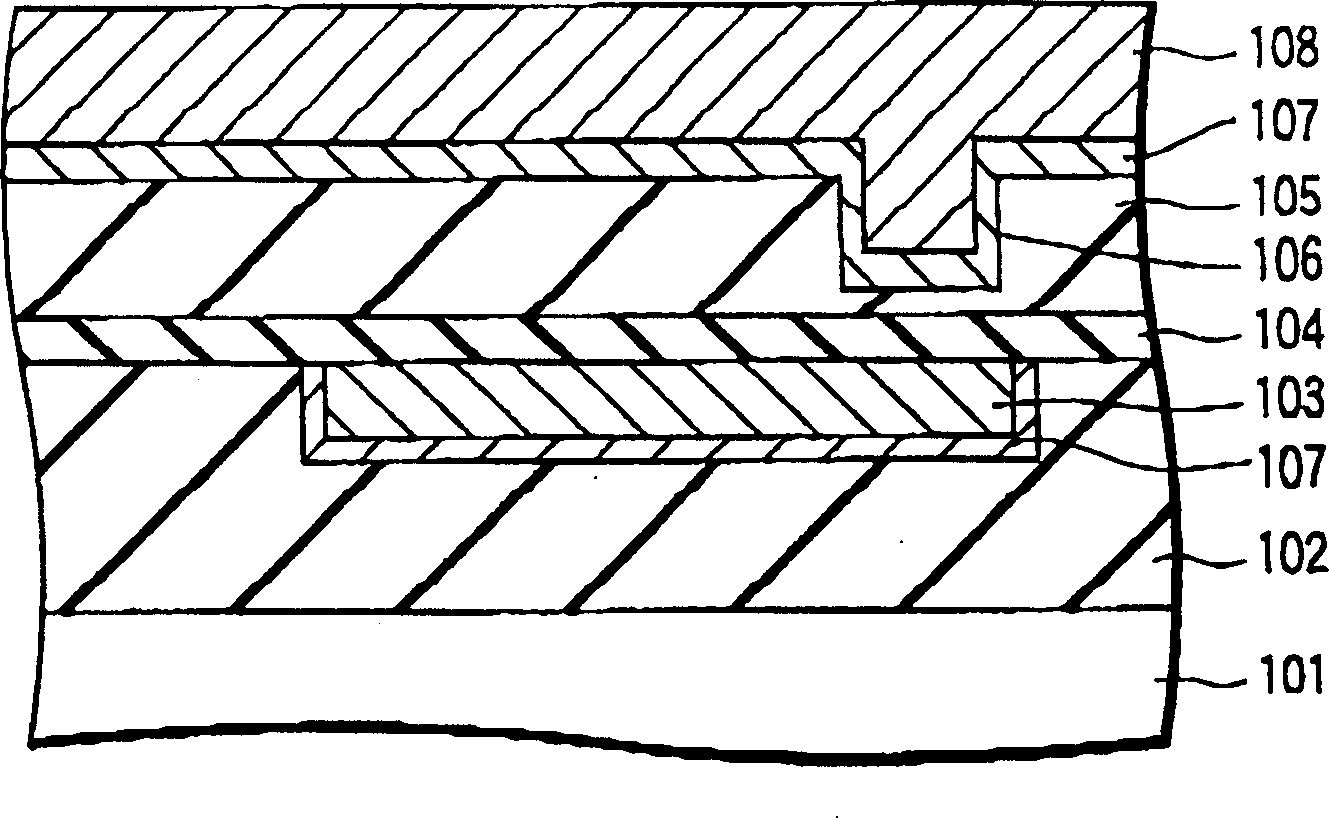

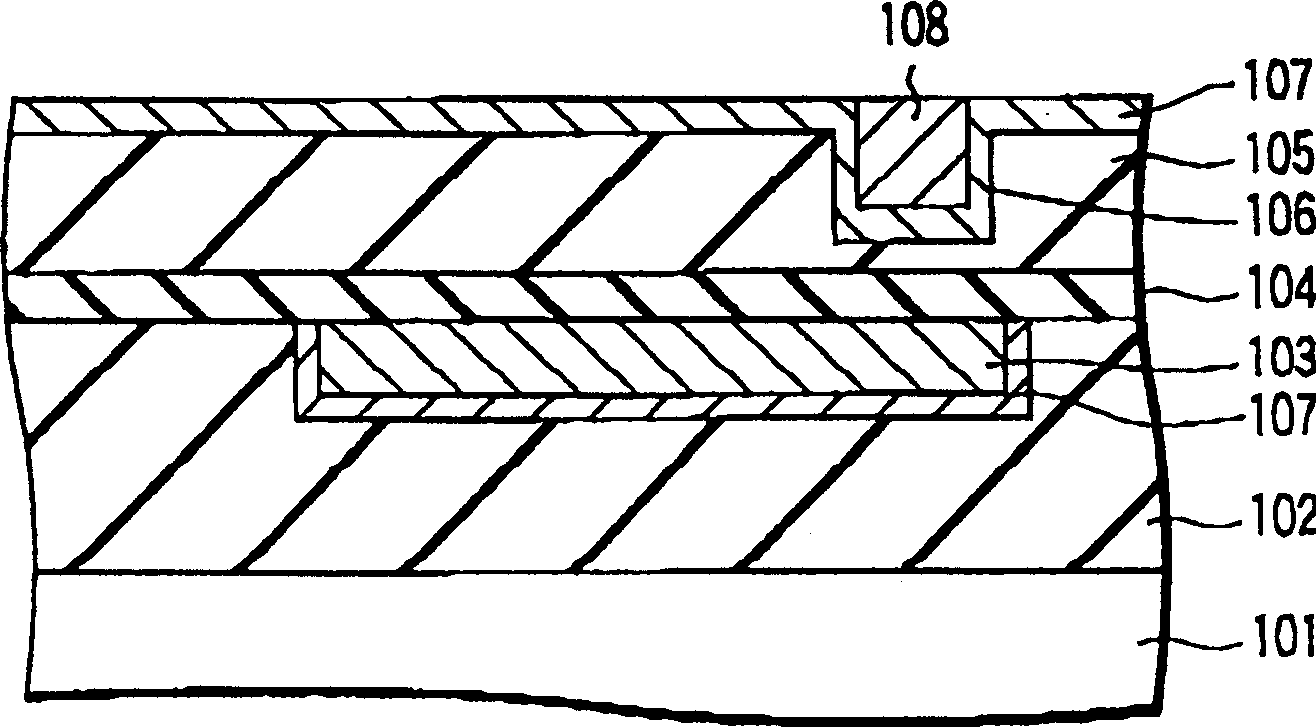

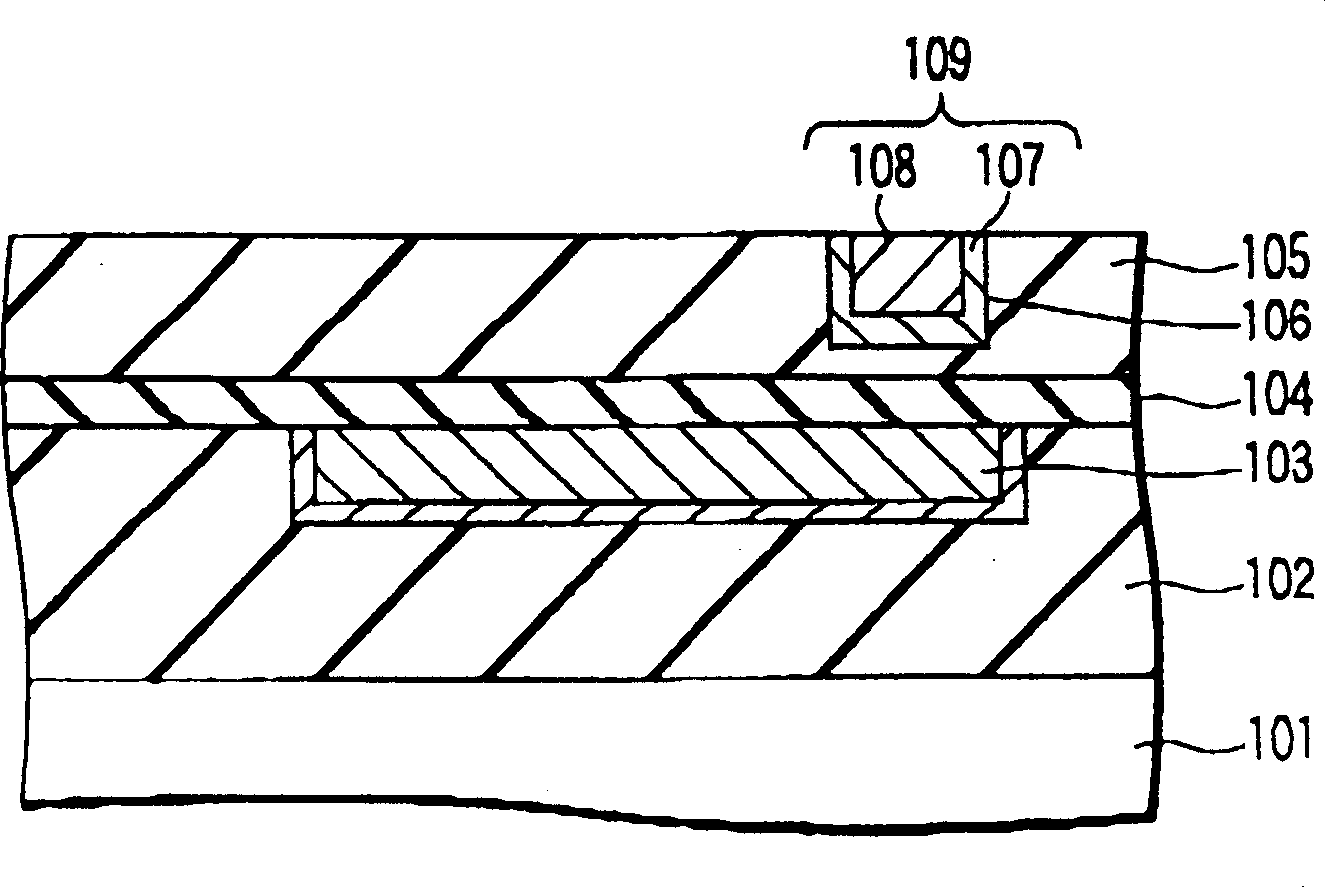

[0042] The formation of the Cu damascene wiring layered structure will now be described with reference to FIG. 1 . like Figure 1A As shown, an insulating film 102 is formed on the surface of a semiconductor substrate 101 having an active element (not shown) formed therein. In addition, a Cu buried wiring 103 is formed in the insulating film 102 while a tantalum nitride (TaN) liner film 107 is interposed between the Cu buried wiring 103 and the insulating film 102 . In addition, a silicon nitride (SiN) film 104 functioning as an interlayer insulating film and a silicon dioxide (SiO 2 ) film 105.

[0043] In the next step, a wiring groove 106 or hole (not shown) for forming a plug for conductively connecting the lower wiring layer to the upper wiring layer is formed in the interlayer insulating film 105. Next, a layered structure of a tantalum nitride (TaN) liner film 107 and a copper (Cu) film 108 is formed in such a manner as to fill up the wiring groove 106 . After formi...

example 2

[0061] The embodiment of Example 2 is directed to an example in which reflectance is measured in situ during CMP processing of a Cu film included in a wafer identical in construction to the wafer in Example 1, that is, the wafer is fabricated so that the multilayer The film is stacked on a semiconductor substrate.

[0062] For this method, the Figures 6A-6C CMP apparatus with the configuration shown. Specifically, Figure 6A is a perspective view showing the structure of the CMP apparatus, Figure 6B Yes Figure 6A Plan view of the CMP apparatus shown in , and Figure 6C Yes Figure 6A Side sectional view of the left part of the CMP apparatus shown in .

[0063] The CMP apparatus was constructed as follows. Specifically, a polishing pad 603 is mounted on a turntable 601, and a wafer 605 supported by a carrier 607 is mounted such that the surface of the wafer 605 to be polished faces downward. A slurry supply nozzle 609 is installed above the polishing pad 603 so that ...

example 3

[0067] This example is for the formation of aluminum pads on copper (Cu) damascene wiring, such as Figures 7A-7C shown. As shown in each figure, copper (Cu) buried wiring 703 is formed in an insulating film 702 on a semiconductor substrate 701 having active elements (not shown) formed therein. In addition, a tantalum nitride (TaN) liner film 700 is interposed between the copper buried wiring 703 and the insulating film 702 . In addition, silicon nitride (SiN) film 704 and silicon dioxide (SiO 2 ) film 705 is sequentially formed on the product structure, followed by patterning on the interlayer insulating film 705 to form a hole 706.

[0068] In the next step, a tantalum (Ta) film 707 as a barrier metal layer and an aluminum (Al) film 708 are formed on the interlayer insulating film 705 in such a manner as to fill up the holes 706 . Then, a resist film is formed on the entire surface, and then the resist film is patterned so that the resist film 709 remains in the portion w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com