Royal jelly refining device

A refining device and technology for royal jelly, which are applied in beekeeping, food preparation, food science, etc., can solve the problems of unstable reticulated mesh, deteriorated products, weakened ultraviolet rays, etc., and achieve simple structure, simple repair and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

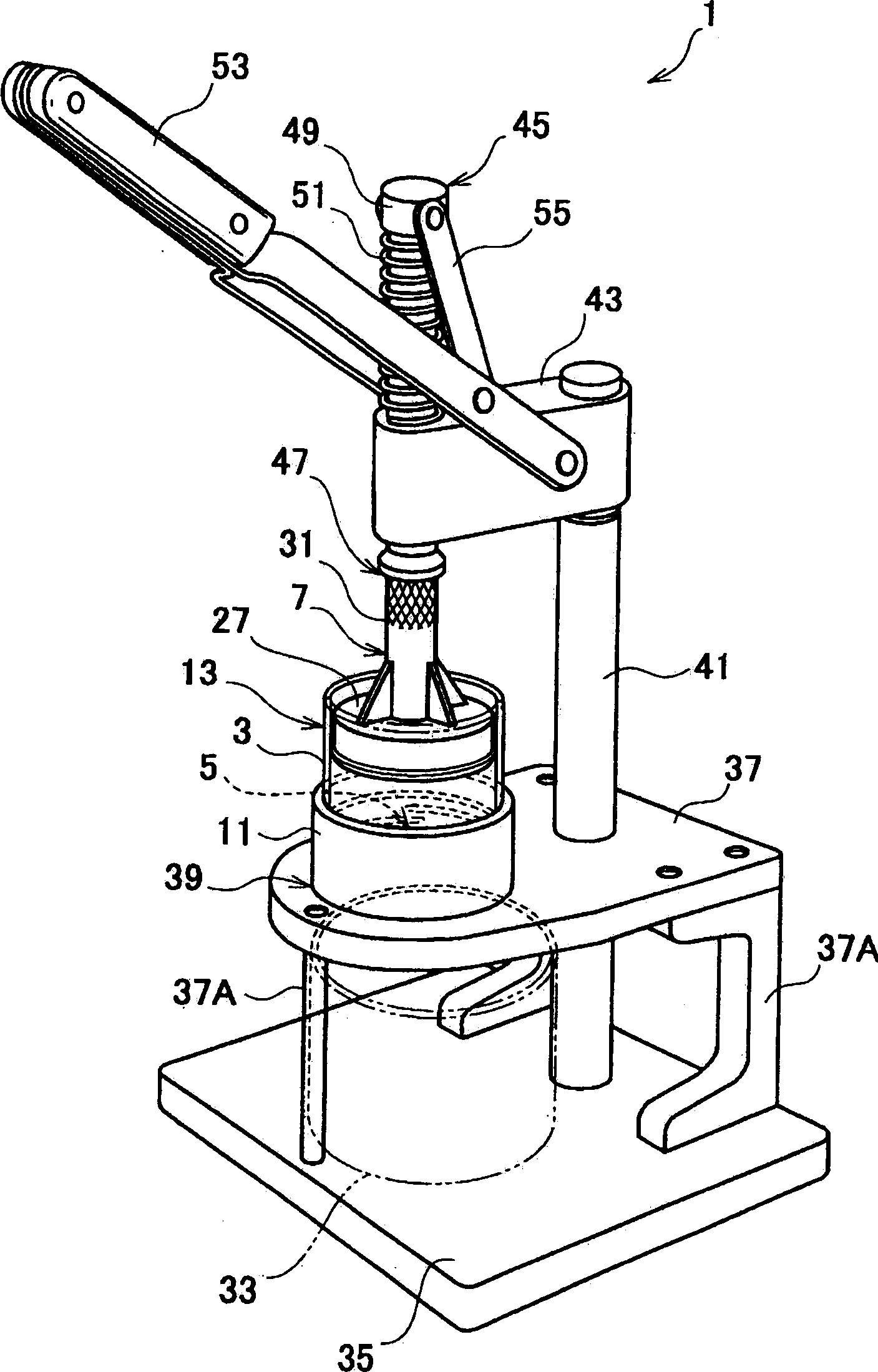

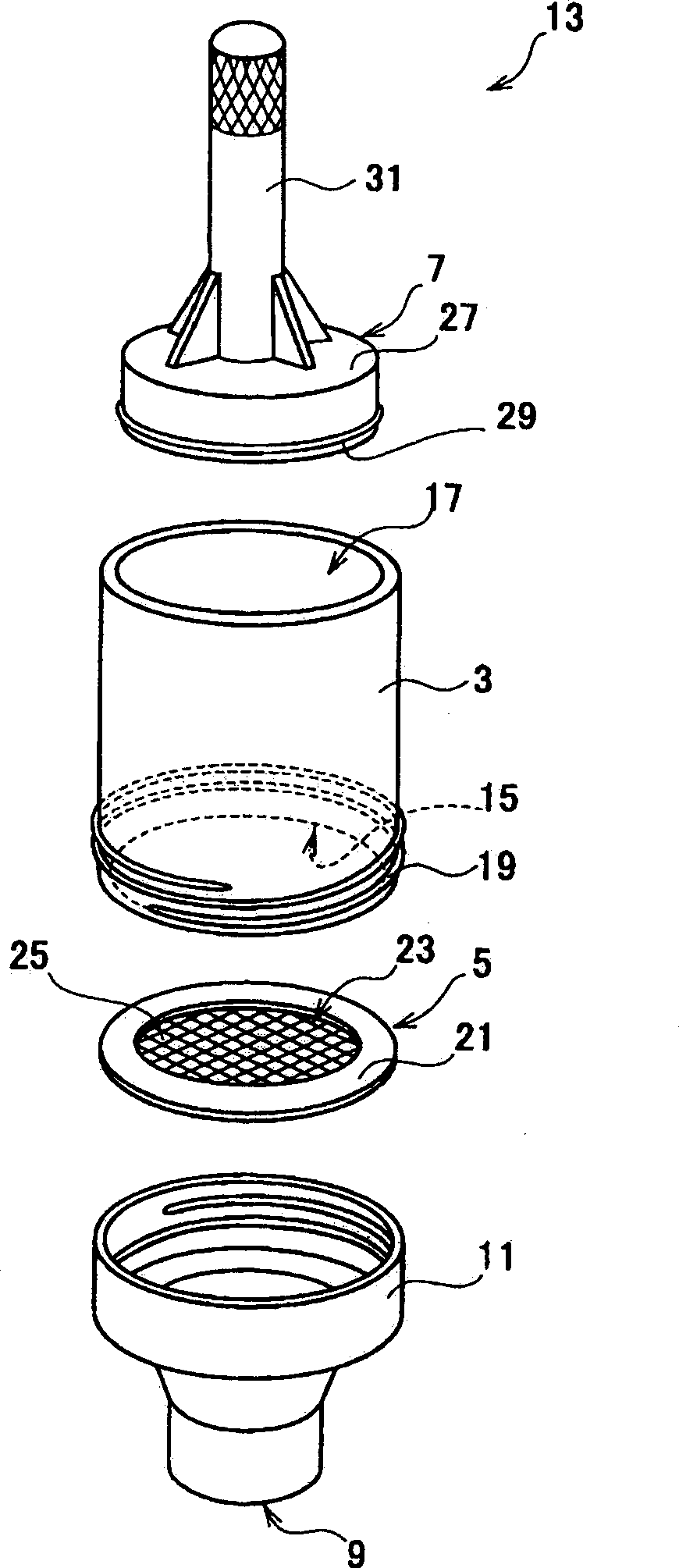

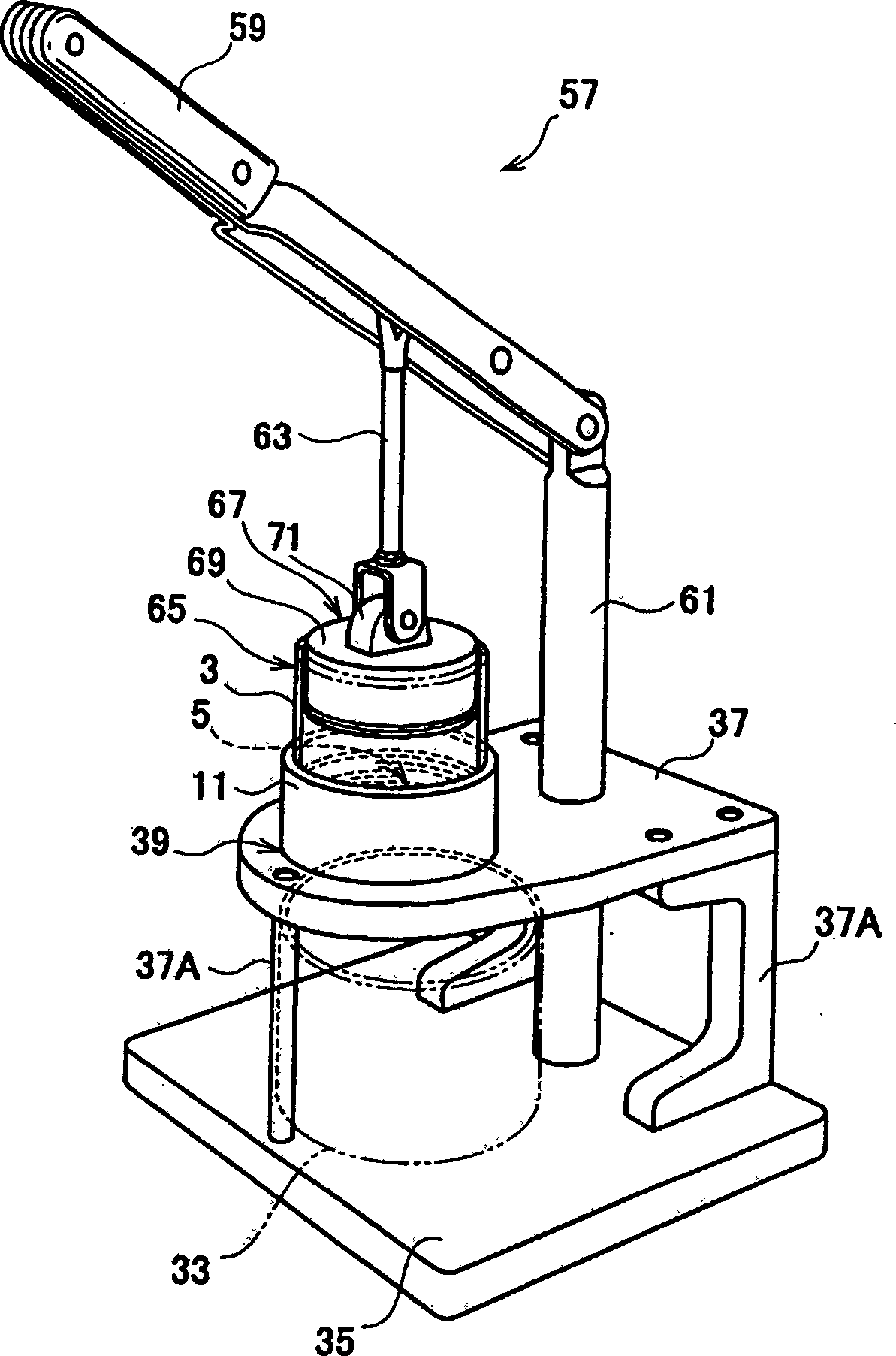

[0048] refer to figure 1 and figure 2 , the refining device 1 of the royal jelly of the first embodiment has a royal jelly refining assembly 13, and this assembly 13 is used for filtering and refining the filtration of the royal jelly dropped into the cylinder portion 3 by the cylindrical cylinder portion 3 that will drop into the royal jelly. A device 5, a plunger 7 for extruding the royal jelly in the cylinder 3 from the filter 5, and a cover 11 having a delivery port 9 for the royal jelly filtered and refined by the filter 5 are sent out.

[0049] More specifically, in the first embodiment, the cylinder portion 3 is made of resin, and the figure 2 In, make the cylinder shape that opening 15,17 is arranged at two ends up and down. exist figure 2 Among them, a screw portion 19 is provided on the outer periphery of one end side of the lower end of the cylinder po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com