Bistable electromagnetic microdriver and mfg. method thereof

A micro-driver and bistable technology, applied in relays, piezoelectric/electrostrictive/magnetostrictive devices, non-polar relays, etc., can solve the problems of low efficiency of electromagnetic action, difficulty in reducing the quality of moving parts, and restrictions on motion response speed, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific design embodiments.

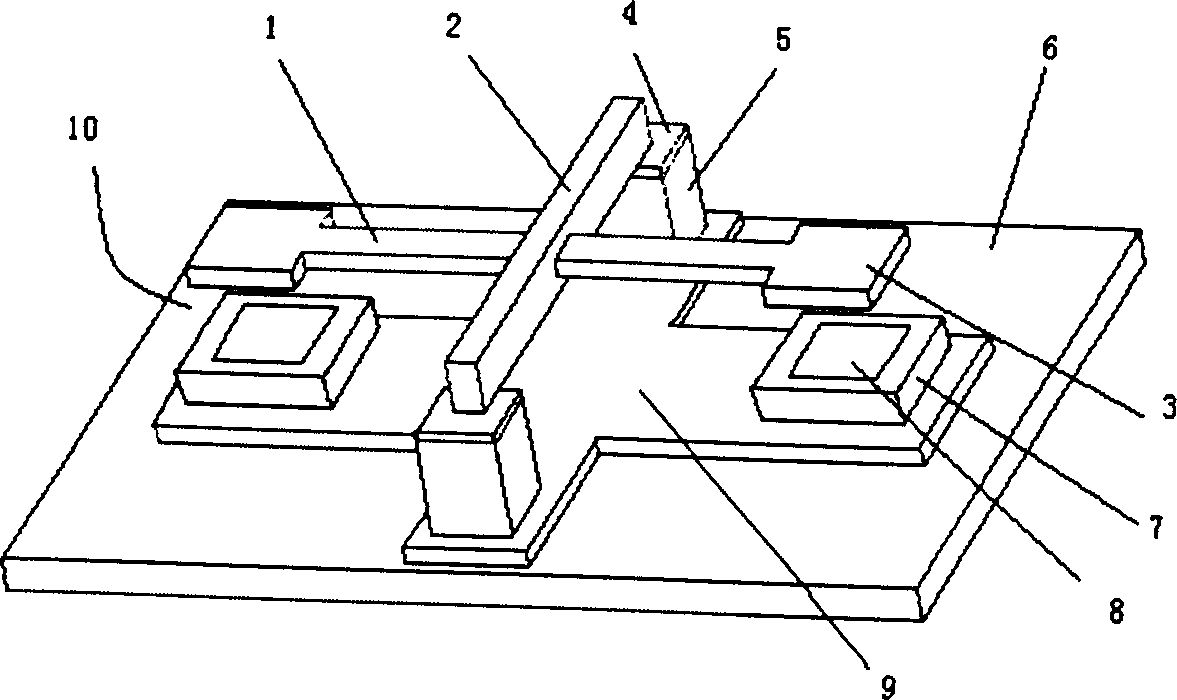

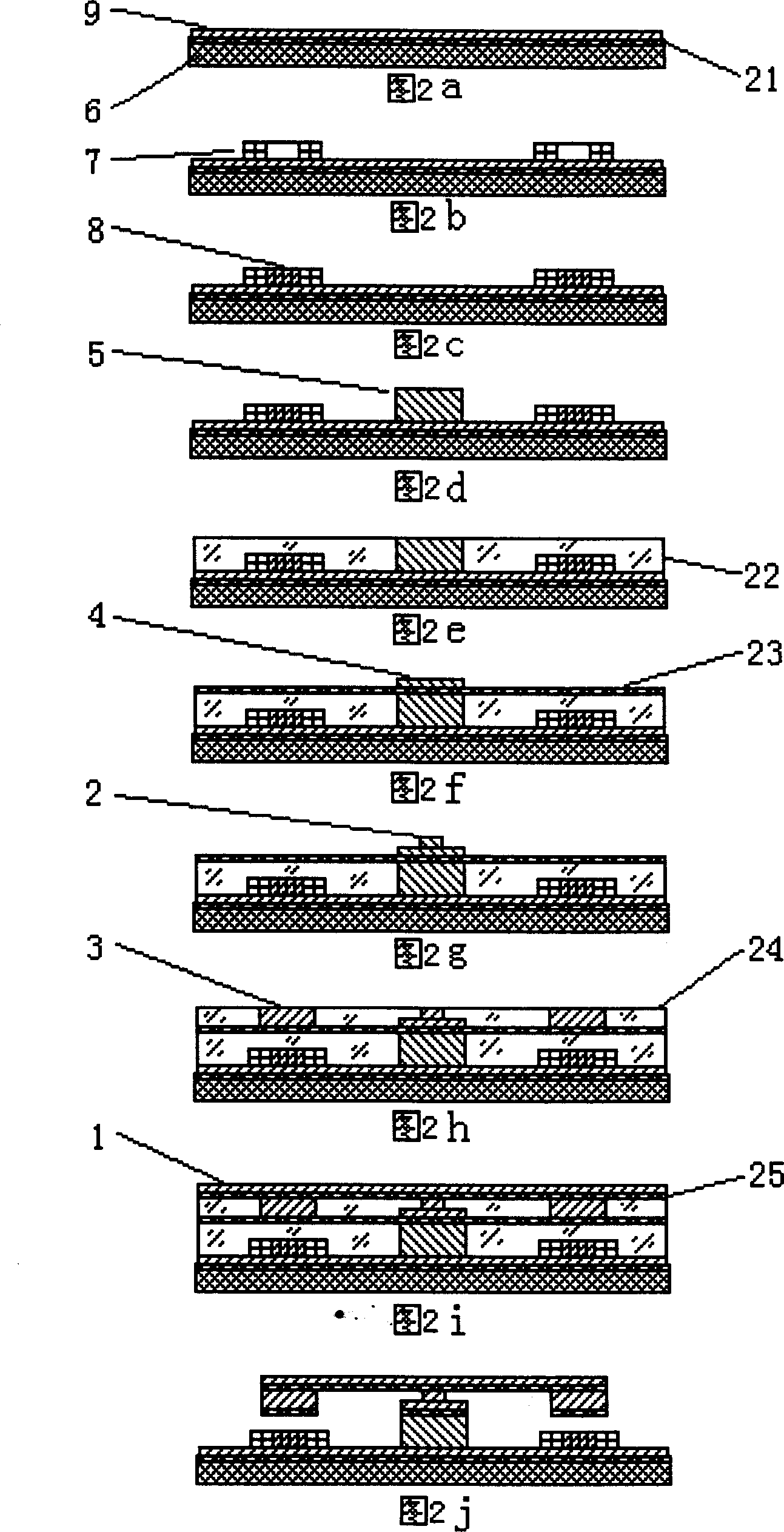

[0023] figure 1It is a schematic three-dimensional structure diagram of a typical design representing the main technical features of the present invention. It should be pointed out that the size ratio of each part in the figure does not necessarily conform to the optimal structural size of the present invention, but only shows the mutual positional relationship of each part.

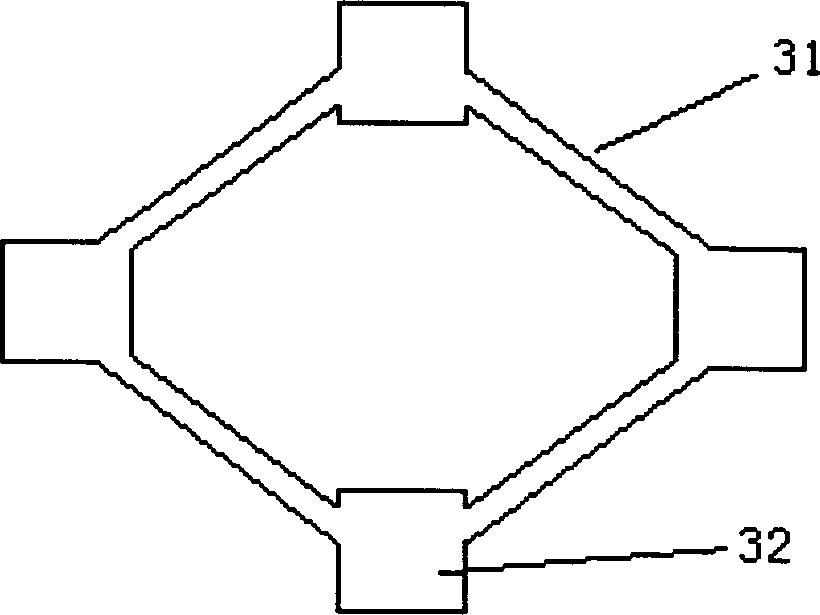

[0024] refer to figure 1 As shown, the bistable micro-actuator of the present invention is based on the soft magnetic substrate 9 distributed on the substrate 6, and a pair of permanent magnet bases 5 are arranged symmetrically on both sides; the soft magnetic torsion beam 2 passes through the soft magnetic transition layer 4 is placed on a pair of bases 5 to form a bridge structure; a set of planar windings 7 are respectively arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com