Process for producing colour plastic dash board of bicycle

A color plastic and manufacturing process technology, applied in fenders, bicycle accessories, transportation and packaging, etc., can solve the problems of high consumption of metal materials, cumbersome processing technology, unfavorable environmental protection, etc., and achieve less consumables, less process flow, improved type fast effect

Inactive Publication Date: 2003-11-26

王家伟

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Most of the existing bicycle fenders are made of metal materials. The processing technology is cumbersome, consumes more metal materials, and the cost is high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

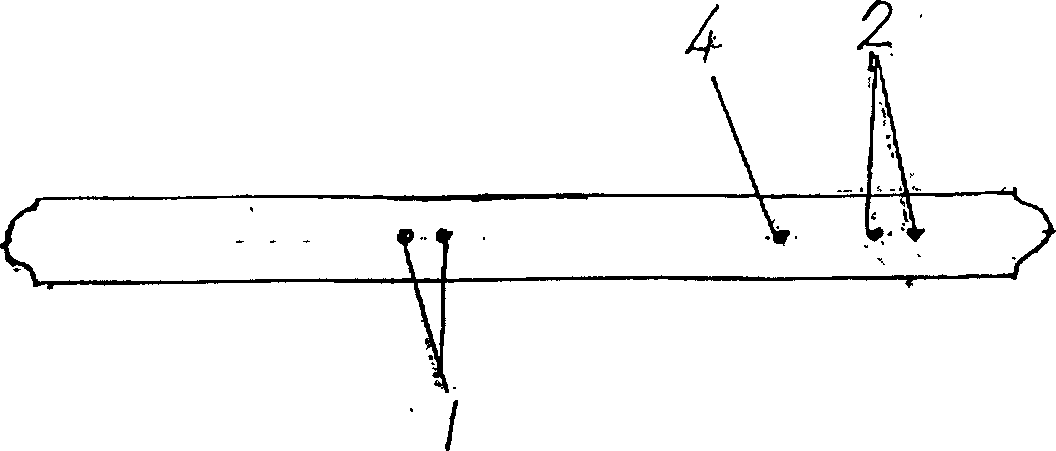

[0018] Embodiment 1. A process for manufacturing a colored plastic fender for bicycles. The process steps are: polypropylene nano-materials→dyeing→injection molding (in a mold)→riveting.

Embodiment 2

[0019] Embodiment 2. A process for manufacturing a colored plastic fender for bicycles. The process steps are: polypropylene nanomaterials → dyeing → extrusion molding → punching → riveting.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

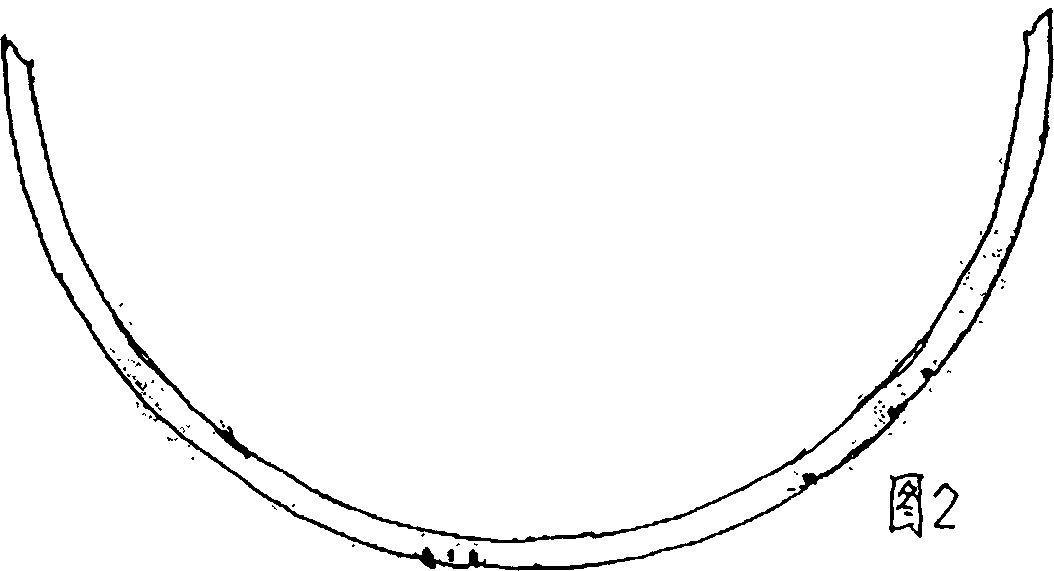

The production process of color plastic dashboard for bicycle may include the steps of: dyeing nano polypropylene material, injection to form and riveting; or include the steps of: dyeing nano polypropylene material, extrusion to form, punching and riveting. The color plastic dashboard is superior to available metal dashboard in that it is light, varying design and color, low cost, being beneficial to environment protection, no dust, high elasticity, high toughness, impact strength and durability similar to metal ones, etc.

Description

technical field [0001] The invention relates to a preparation method of a bicycle colored plastic fender. Background technique [0002] Bicycles are a very common means of transportation, and the annual market demand in my country alone is about 90 million. Most of the existing bicycle fenders are made of metal materials, which are complicated in processing technology, consume a lot of metal materials, and have high costs. [0003] The manufacturing process of the metal fender is: metal sheet → leaking piece (consumes a lot of steel, because there is a lot of cutting material) → punching (in a special mold) → anti-corrosion (decontamination in a special liquid) → baking paint → riveting → Inspection → Packing. SUMMARY OF THE INVENTION [0004] The purpose of the present invention is to avoid the deficiencies in the prior art, and to provide a low-cost manufacturing process for bicycle colored plastic fenders without metal materials. [0005] The following technical solu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B62J15/00

Inventor 王家伟

Owner 王家伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com