Method for firing refractory brick

A technology of refractory bricks and brick stacks, which is applied in the field of brick firing, can solve problems such as ineffectiveness, and achieve the effects of reducing labor, increasing output, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below

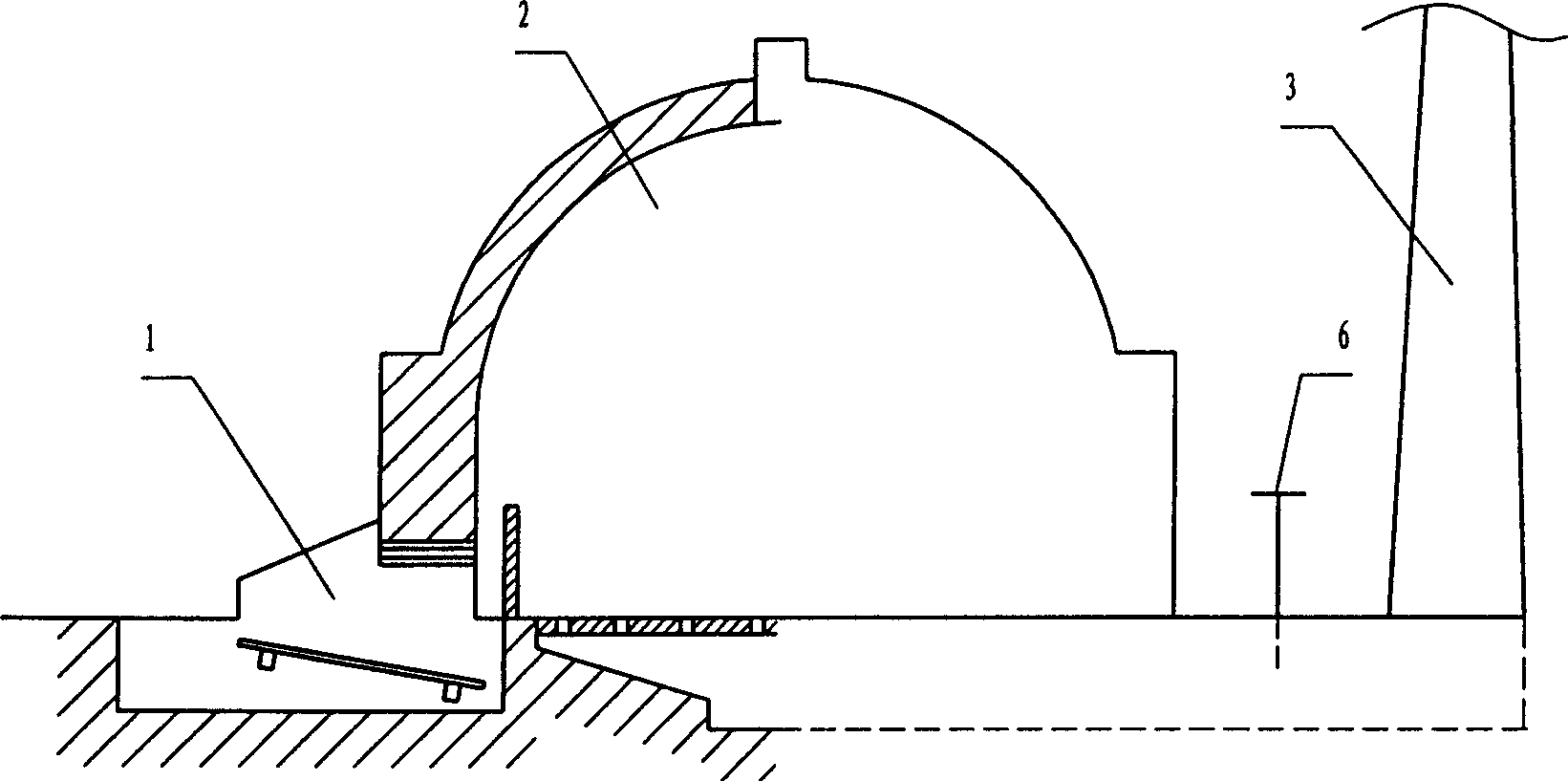

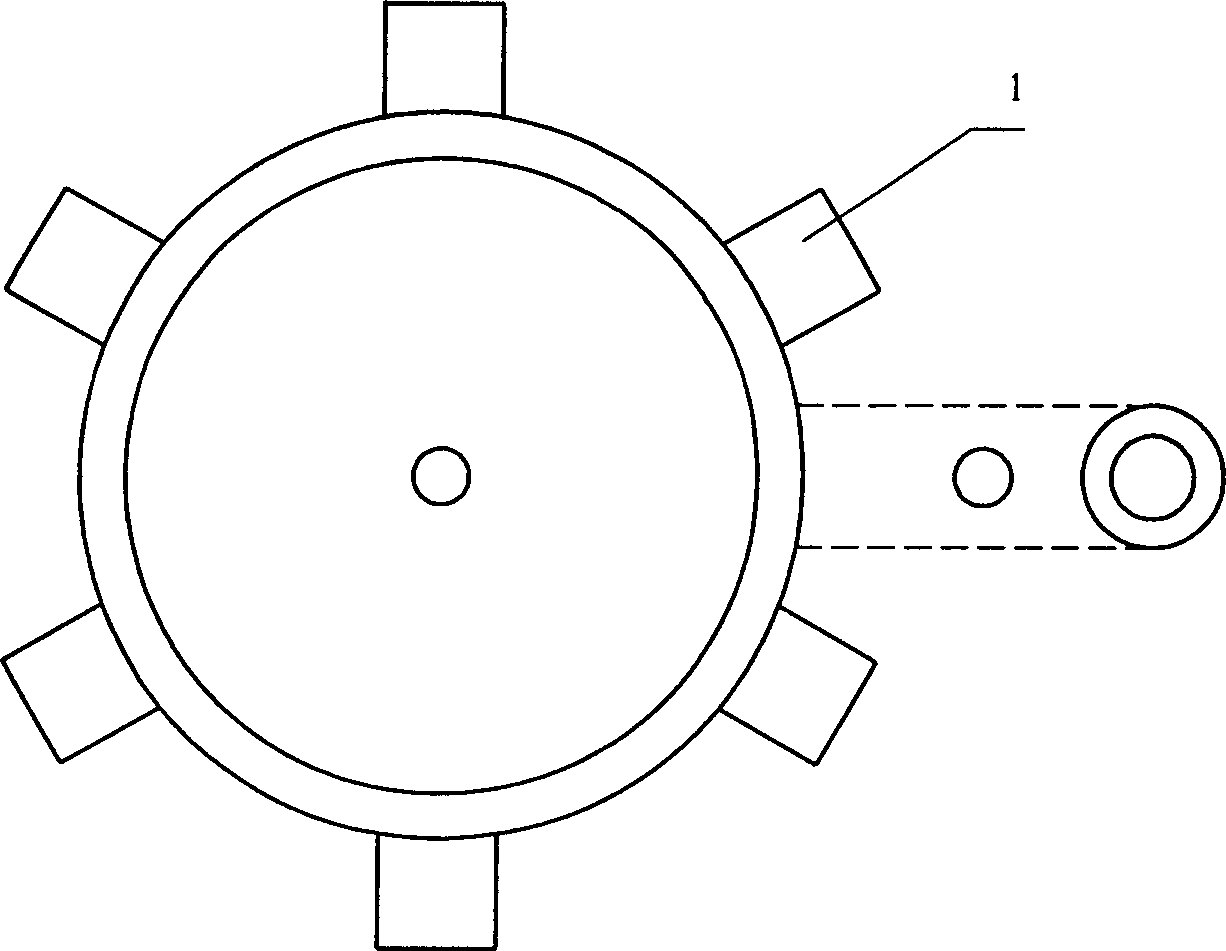

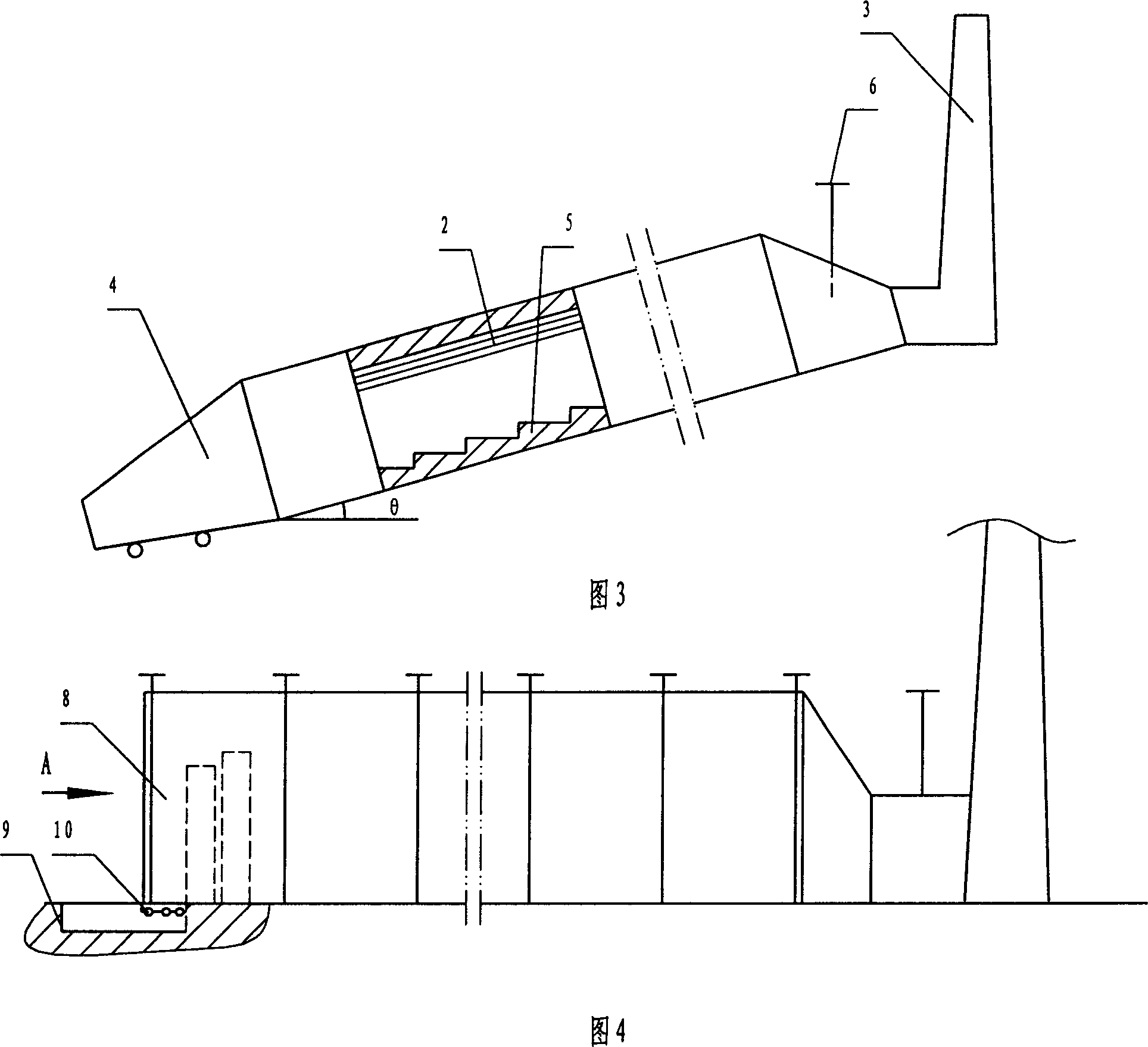

[0015] The invention relates to a firing method of refractory bricks, which comprises the following steps: 1, providing a kiln for firing refractory bricks; 2, mixing coal blocks and refractory bricks in the same kiln chamber; 3, igniting and burning coal 4. Open the air duct to open the kiln door. The material of general briquette is anthracite, and briquette can be honeycomb shape such as square briquette, as shown in Figure 3, kiln comprises ignition chamber 4, kiln chamber 2, chimney 3, and the bottom of ignition chamber 4 is inclined plane, and the bottom of kiln chamber 2 Step 5, the bottom slope θ between the ignition chamber 4 and the kiln chamber 2 is 10-20 degrees, preferably 10-15 degrees, and the step surface is a plane, so that the brick stack and the coal stack will not slide down the slope, as shown in Figure 4 , Shown in 5, when the height of chimney 3 is greater than the length 5-10m of kiln chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com