Catalyst for hydrogenation treatmet of gas oil and method for prepn. thereof and process for hydrogenation treatment of gas oil

A catalyst and gas oil technology, applied in the field of catalysts for hydrotreating gas oil, can solve the problems of low efficiency, complicated steps, short catalyst life and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

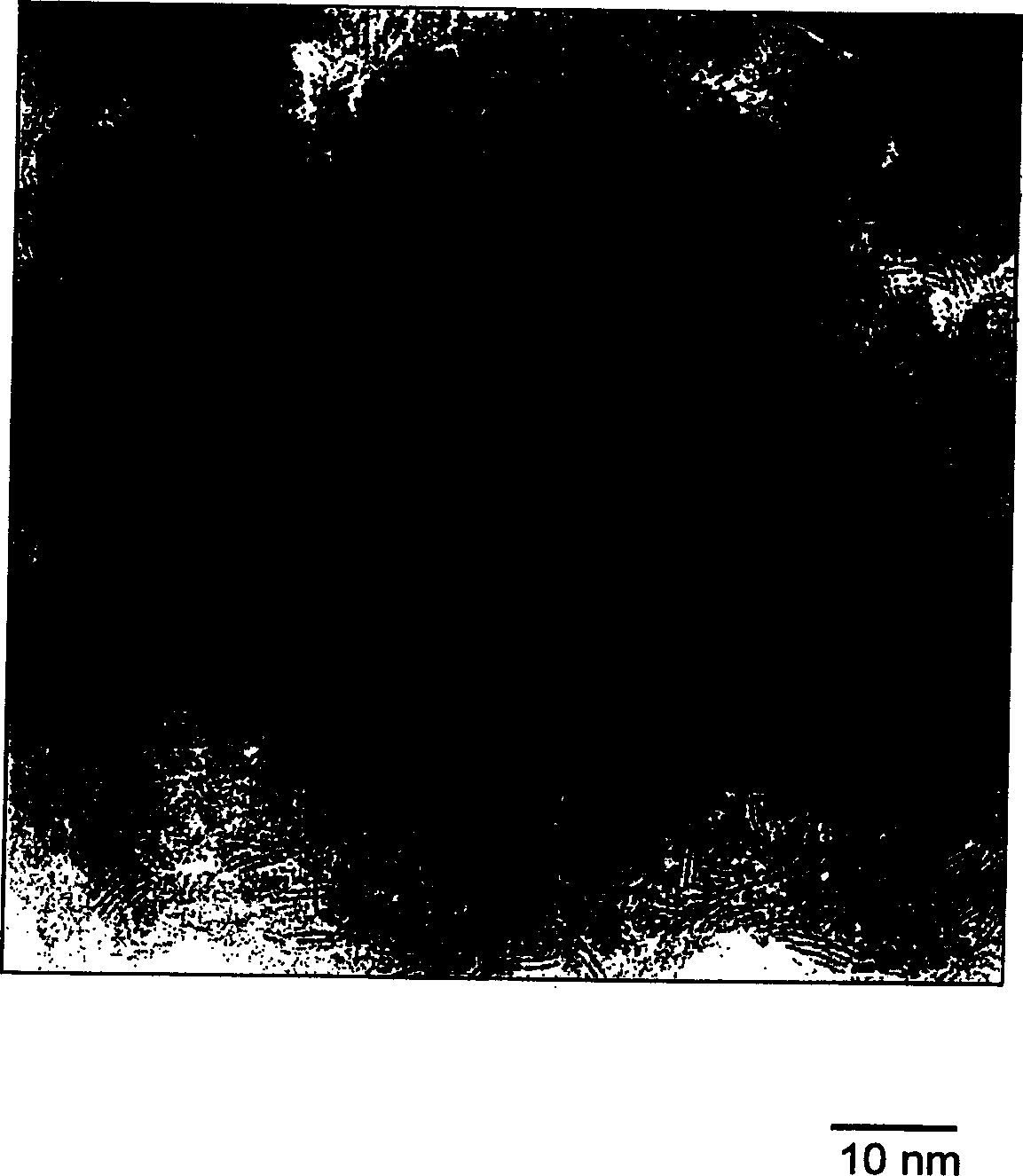

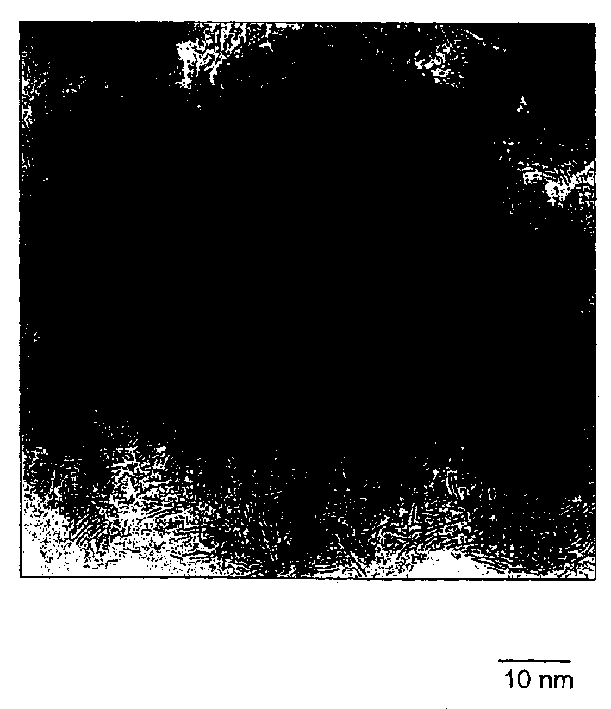

Image

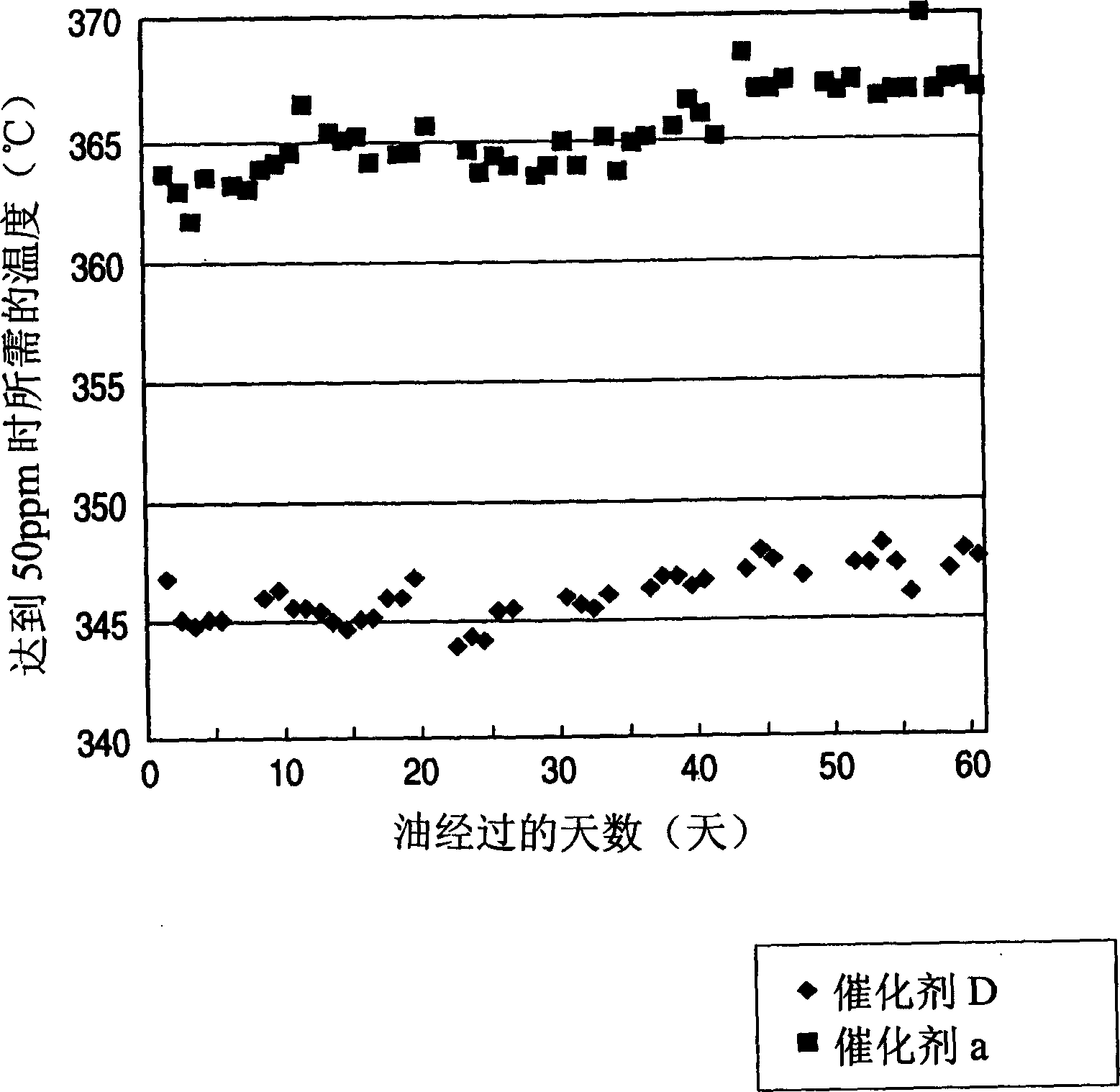

Examples

Embodiment 1

[0115] Silica and alumina hydrate were kneaded together, the obtained mixture was extruded and then calcined at 600° C. for 2 hours to obtain a columnar silica-alumina composite support (diameter 1 / 16 inch) The weight ratio of silicon / alumina is 1 / 99; the pore volume is 0.70ml / g; the specific surface area is 359m 2 / g; average pore diameter, 70 Angstroms).

[0116] 7.48 g of cobalt citrate and 1.17 g of phosphoric acid (85% aqueous solution) were added to 20.3 g of ion-exchanged water, followed by heating to 80° C. and stirring for 10 minutes. Subsequently, 11.41 g of phosphomolybdic acid was added thereto and dissolved, followed by stirring at the same temperature for 15 minutes to prepare an impregnation solution. The pH of this impregnation solution was 0.52.

[0117] 30.0 g of silica-alumina composite support was added to the eggplant-shaped flask. The entire impregnation solution was added to it using a pipette. The support was soaked in the solution at about 25°C for...

Embodiment 2

[0120] SiO 2 / Al 2 o 3 SHY zeolite powder (average particle diameter 3.5 μm; 87% of all zeolite particles having a particle diameter of 6 μm or less) at a molar ratio of 6 was kneaded together with alumina hydrate. The obtained mixture was extruded and then calcined at 600° C. for 2 hours to obtain a columnar zeolite-alumina composite support with a diameter of 1 / 16 inch (zeolite / alumina weight ratio 7 / 93; pore volume 0.69 ml / g; Specific surface area 374m 2 / g; average pore diameter 67 Angstroms).

[0121] 7.48 g of cobalt citrate and 1.17 g of phosphoric acid (85% aqueous solution) were added to 20.3 g of ion-exchanged water, followed by heating to 80° C. and stirring for 10 minutes. Subsequently, 11.41 g of phosphomolybdic acid was added thereto and dissolved, followed by stirring at the same temperature for 15 minutes to prepare an impregnation solution. The pH of this impregnation solution was 0.52.

[0122] 30.0 g of the zeolite-alumina composite support was added t...

Embodiment 3

[0125] 7.91 g of cobalt citrate and 1.12 g of phosphoric acid (85% aqueous solution) were added to 20.2 g of ion-exchanged water, followed by heating to 80° C. and stirring for 10 minutes. Subsequently, 14.50 g of phosphomolybdic acid was added thereto and dissolved, followed by stirring at the same temperature for 15 minutes to prepare an impregnation solution. The pH of this impregnation solution was 0.54.

[0126] Into the eggplant-shaped flask was added 30.0 g of the same zeolite-alumina composite support as in Example 2. The entire impregnation solution was added to it using a pipette. The support was soaked in the solution at about 25°C for 3 hours.

[0127] Thereafter, the carrier was dried in a nitrogen flow, and then dried in a muffle furnace under air flow, atmospheric pressure, and 120° C. for about 16 hours to obtain catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com