Central colony programmed logic control hydraulic lifting system and construction method for lifting thereof

A program logic and central cluster technology, applied in the direction of hoisting devices, hoisting frames, etc., can solve the problems of no steel strand stress in the hoisting system, low lifting balance of the hoisting system, and large distribution of hoisting point distances, so as to save installation lines , Low cost of system equipment, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

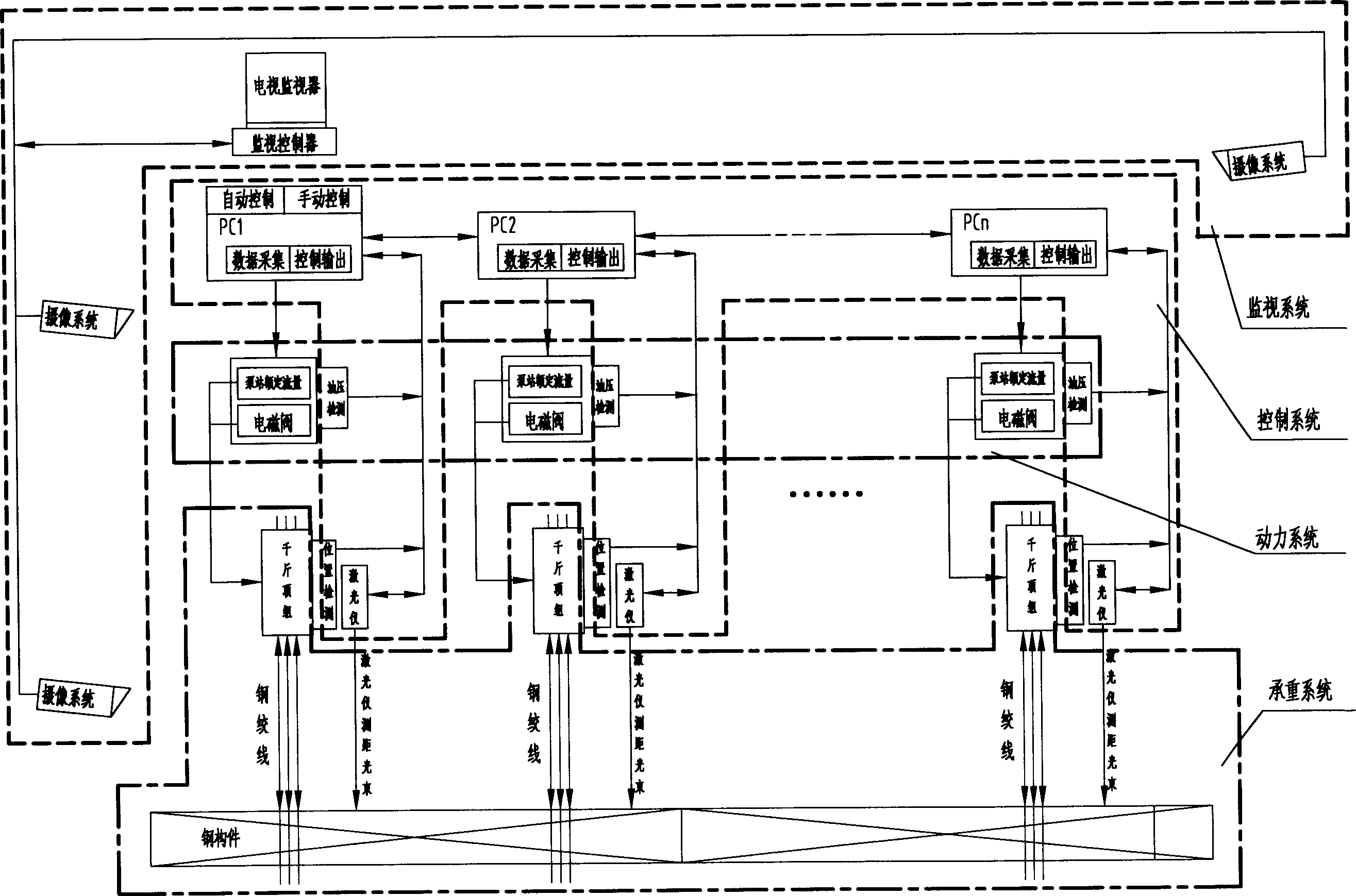

[0061] A manually controlled central cluster program logic controls the hydraulic lift system. Such as figure 1 Shown: The system includes a load-bearing system composed of steel strands connecting jacks and components, a power system composed of multiple pump stations with rated flow according to the number of jacks, a control system composed of manual control and automatic control devices, connected by solenoid valves The control system and the power system; the jack and the power system are connected by a hydraulic oil circuit, and 1 to 4 rated flow pump stations are used in the power system to supply oil to the master cylinder of the jack.

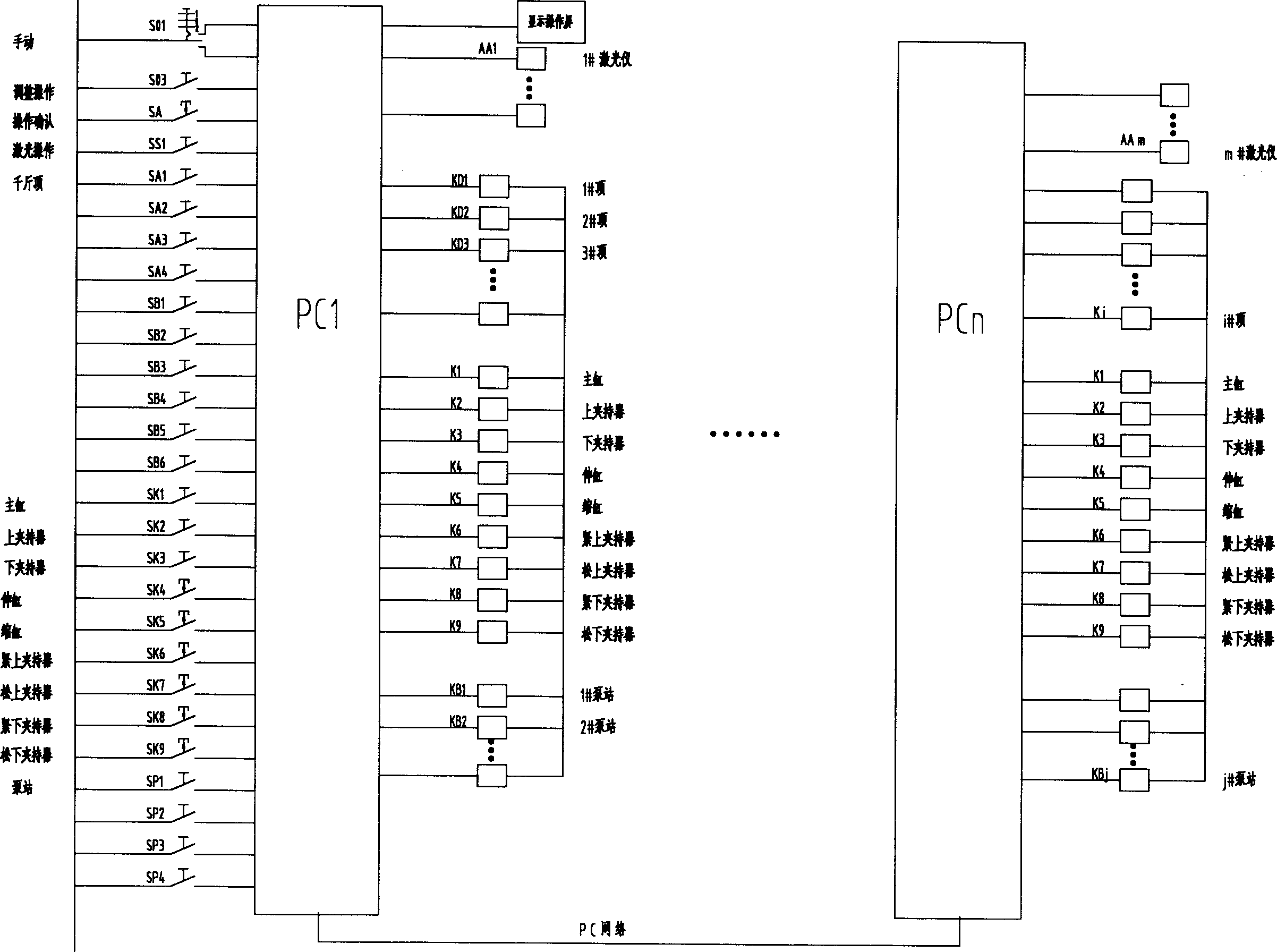

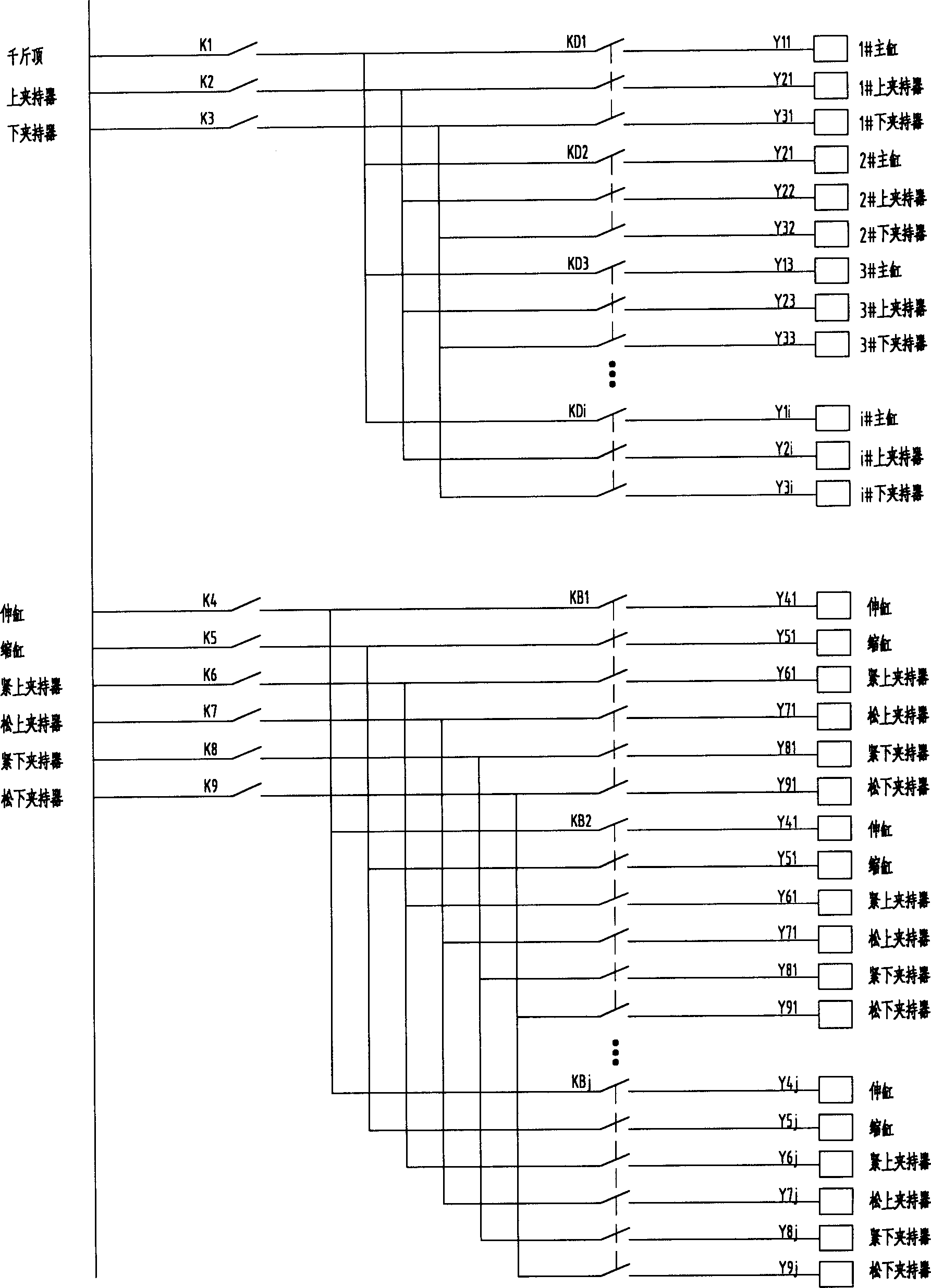

[0062] The control system is a manual control system composed of a manual operation switch group, a computer network composed of n programmable controller PC groups, relays KD1~KDi, n K1~K9, KB1~KBj; the manual operation switch group Each group of switches is respectively connected to the digital input terminal of the programmable con...

Embodiment 2

[0071] The central cluster program logic control hydraulic lifting system with "manual adjustment steel strand stress combination system", the basic structure of the control system is the same as the first embodiment, the difference is: the system also includes "detected by the laser instrument and "Manual adjustment steel strand stress combination system" composed of manual control operation device, the combination system is composed of laser rangefinder, programmable controller, solenoid valve, jack, steel strand, the RS232 communication port of laser rangefinder through The photoelectric isolation remote transmitter is connected with the RS232 communication port of the computer, and forms a measurement connection with the component through the laser ranging beam, and the programmable controller starts the RS232 communication port and the laser instrument for data exchange according to the RS232 communication protocol; the laser distance measuring instrument The emitted dista...

Embodiment 3

[0073] A central cluster program logic control hydraulic lifting system including manual control, automatic control and adjustment control, the basic structure of the system is the same as that of Embodiment 1 or Embodiment 2, also as figure 1 Shown: The system includes load-bearing system, power system and control system.

[0074] The difference is that the control system also includes a computer network composed of automatic operation switches, travel switch groups, n programmable controller PCs, relays KD1~KDi, KB1~KBj, n K1, n Kz2 , n Kz3, n K4 ~ K9 composed of automatic control system, the specific connection method is: connected to the digital input of programmable controller PC1 by switches S01, S04, S05, S06, S08, S09, S10, S119, SS1 terminal; the travel switches SQ11~SQ1i, SQ21~SQ2i, SQ31~SQ3i, SQ41~SQ4i, SQA1~SQAi, SQB1~SQBi are connected to the digital input terminal of the programmable controller PC, n K1, n Kz2, n Kz3 are respectively connected to the digital out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com