Modular subframe assembly for a motor vehicle

A motor vehicle, modular technology, applied in the direction of motor vehicles, vehicle parts, vehicle springs, etc., can solve problems such as limited flexibility, and achieve the effect of increasing flexibility and reducing noise transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

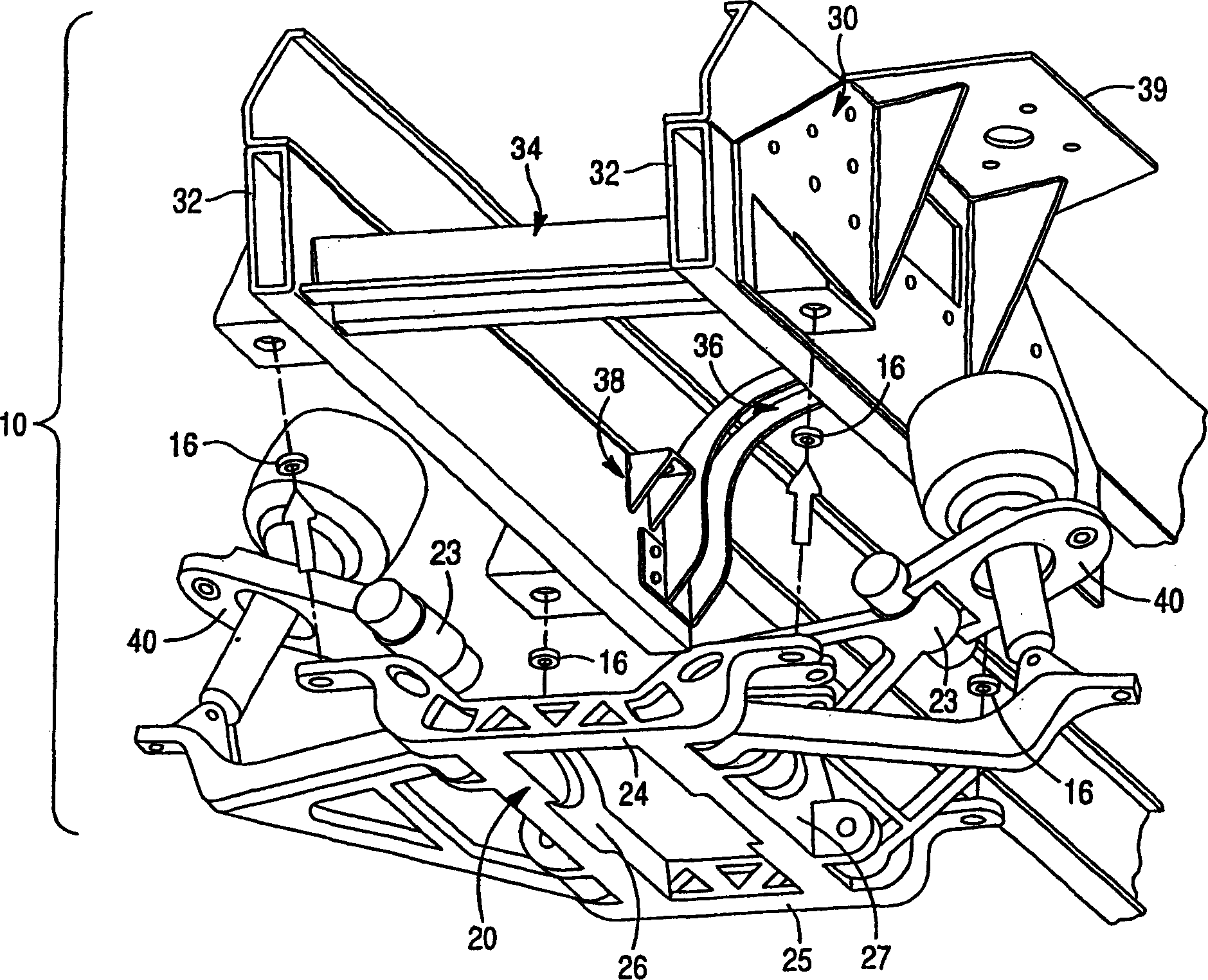

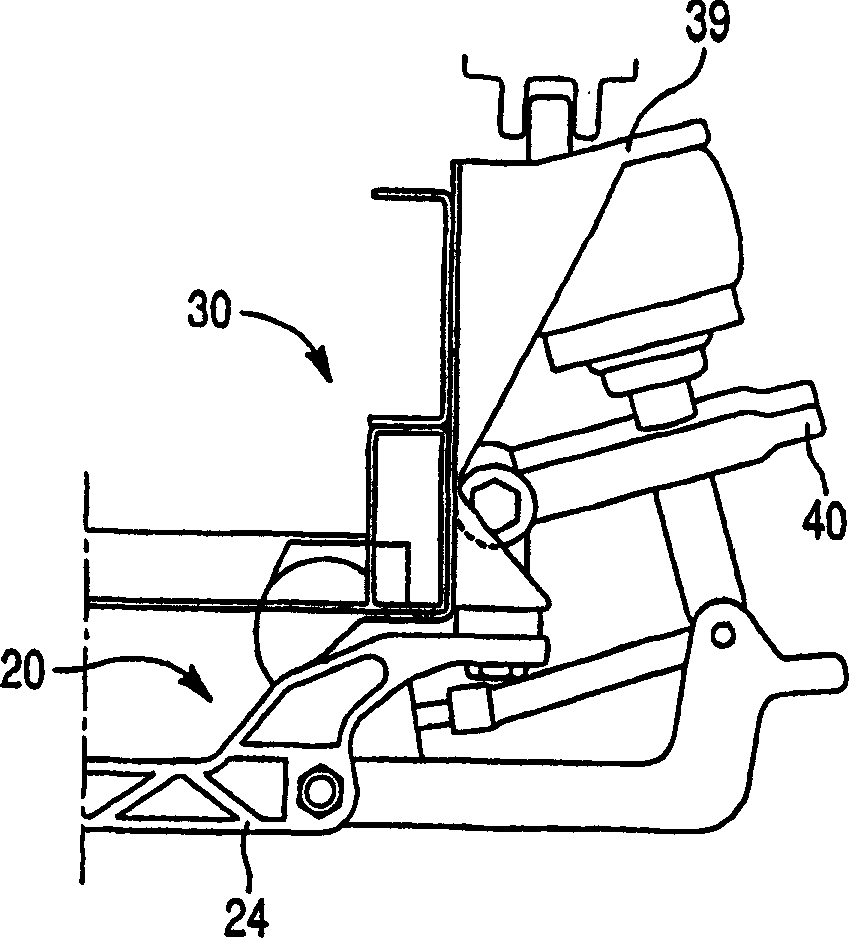

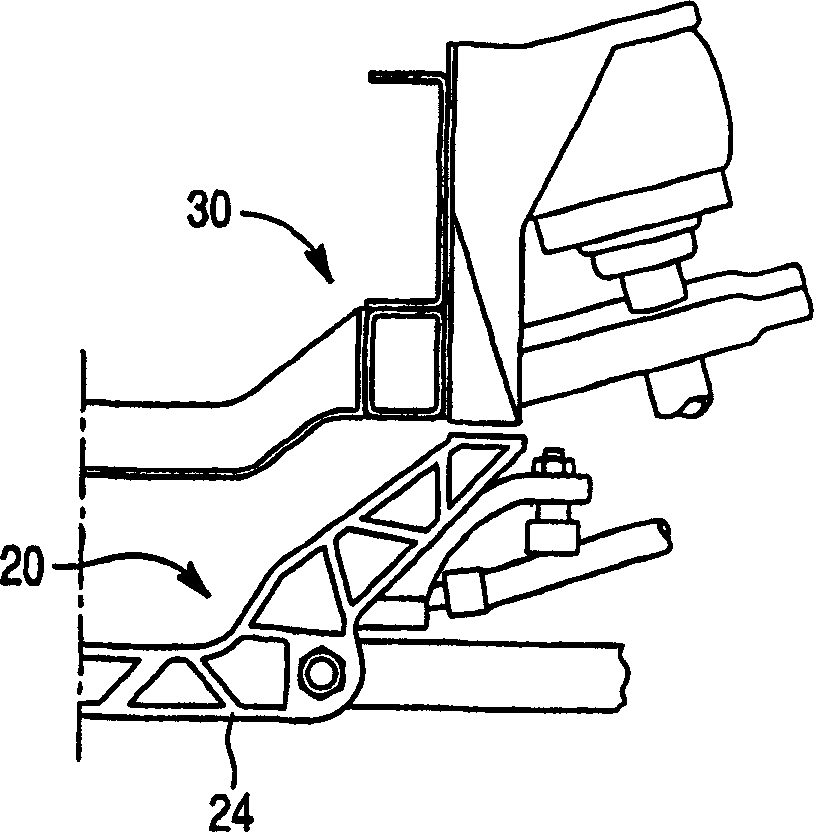

[0024] refer to figure 1 , the first embodiment of the present invention will now be described. The modular subframe assembly 10 of the present invention includes a modular one-piece cast aluminum subframe lower portion 20, a steel chassis reinforcement upper portion 30, and a vibration isolation liner interposed between the upper and lower portions 20, 30 of the subframe assembly 10 Set of 16.

[0025] exist figure 1 In the embodiment shown in the upper section 30 is provided with a pair of aligned steel chassis reinforcement beams 32, a front engine mounting cross member 34, a rear engine mounting cross member 36 and an engine mounting bracket 38 (only one shown). Suspension mounting brackets 39 are also provided on the upper portion 30 .

[0026] The lower portion 20 is shown as a one-piece cast aluminum body formed to mount the upper and lower arms of the suspension system. Alternatively, a separate bracket 23 is used to mount the upper control arm 40 to the lower subf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com