Optical packaging equipment

A packaging device and optical technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve problems such as over-density pins, increase packaging volume, and affect the performance of optical components, so as to reduce parasitic capacitance and overcome short-circuit phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

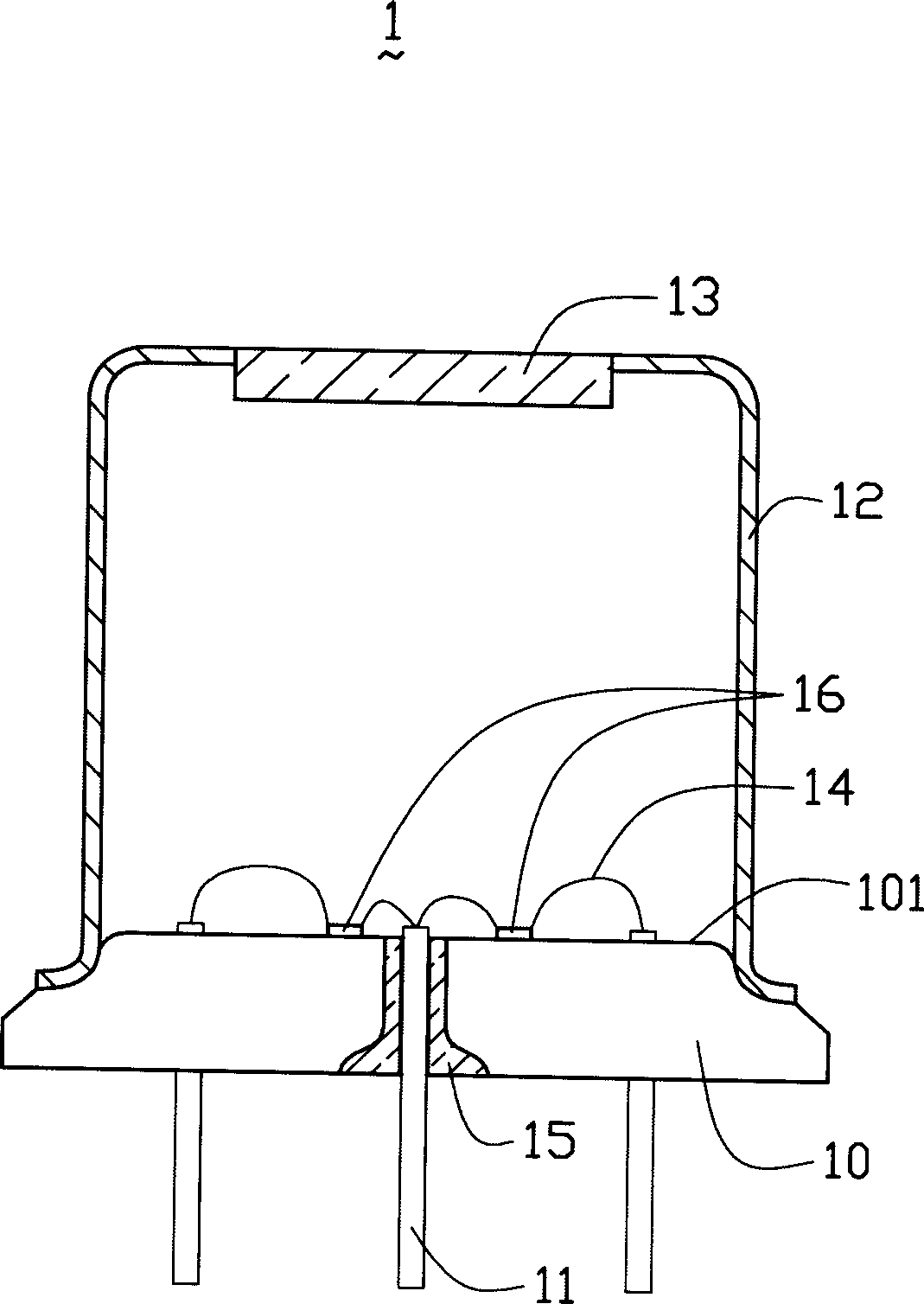

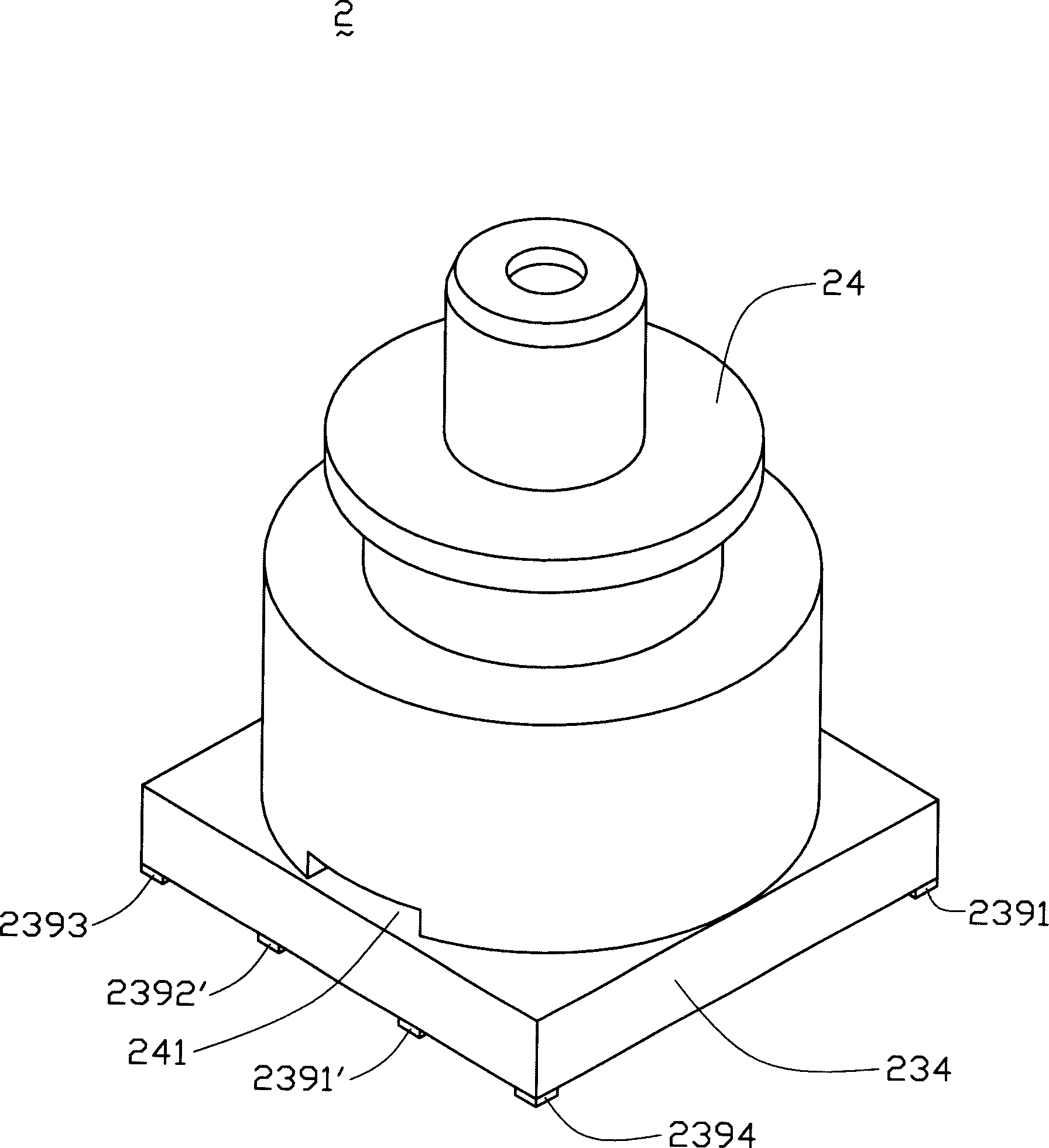

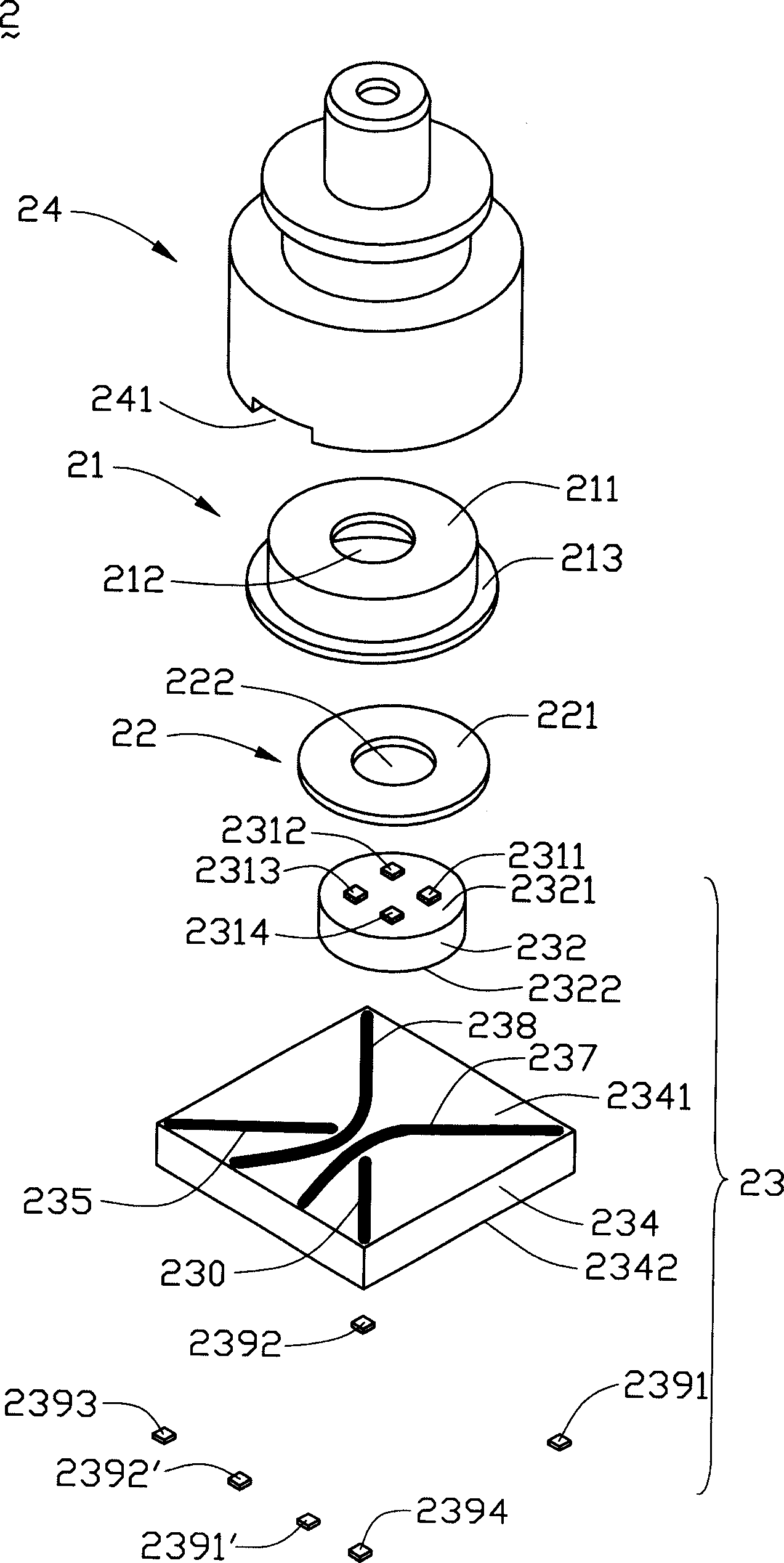

[0015] Please refer to figure 2 and image 3 The optical packaging device 2 of the present invention includes a cover body 21 , a lens component 22 , and a base 23 . The cover body 21 and the base 23 are tightly sealed to form a storage space for accommodating and protecting optical components (not shown) inside the optical packaging device 2 . The optical packaging device 2 further includes a connection part 24, which is located on the outside of the cover body 21, for connecting to an external light guide (such as an optical fiber) or other optical devices (not shown in the figure), and an opening 241 is provided at the bottom of the connection part 24 to facilitate Disassemble from the cover body 21.

[0016] The cover 21 is in the shape of a pot, generally made of metal material, and includes a top 211 and a bottom 213 . An opening 212 is disposed in the middle of the top 211 for transmitting or receiving light signals. The upper surface of the bottom edge 213 fits wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com