Laser welding absorption film

A technology of absorbing thin film and laser welding, which is applied in the direction of laser welding equipment, welding equipment, superimposed layer coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

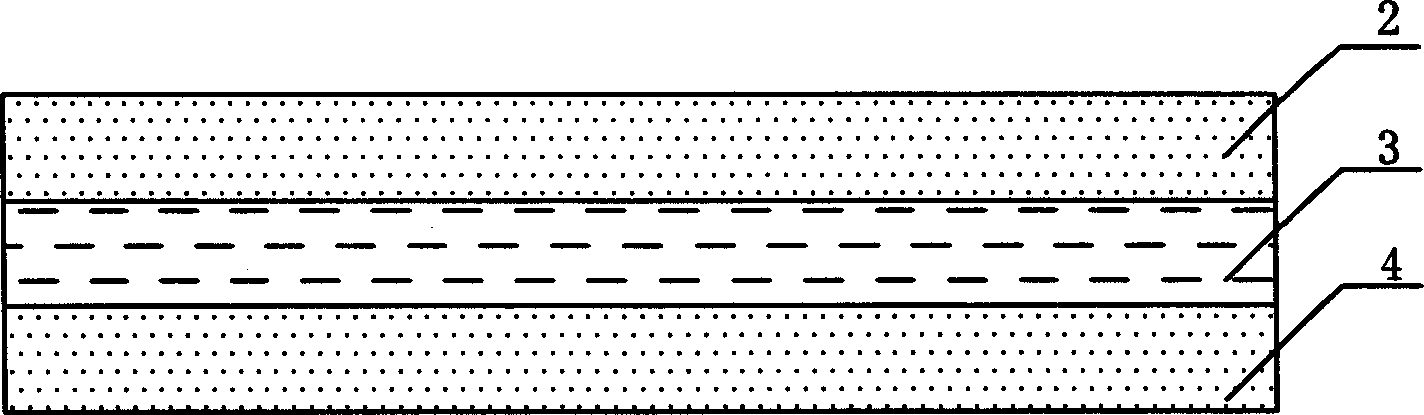

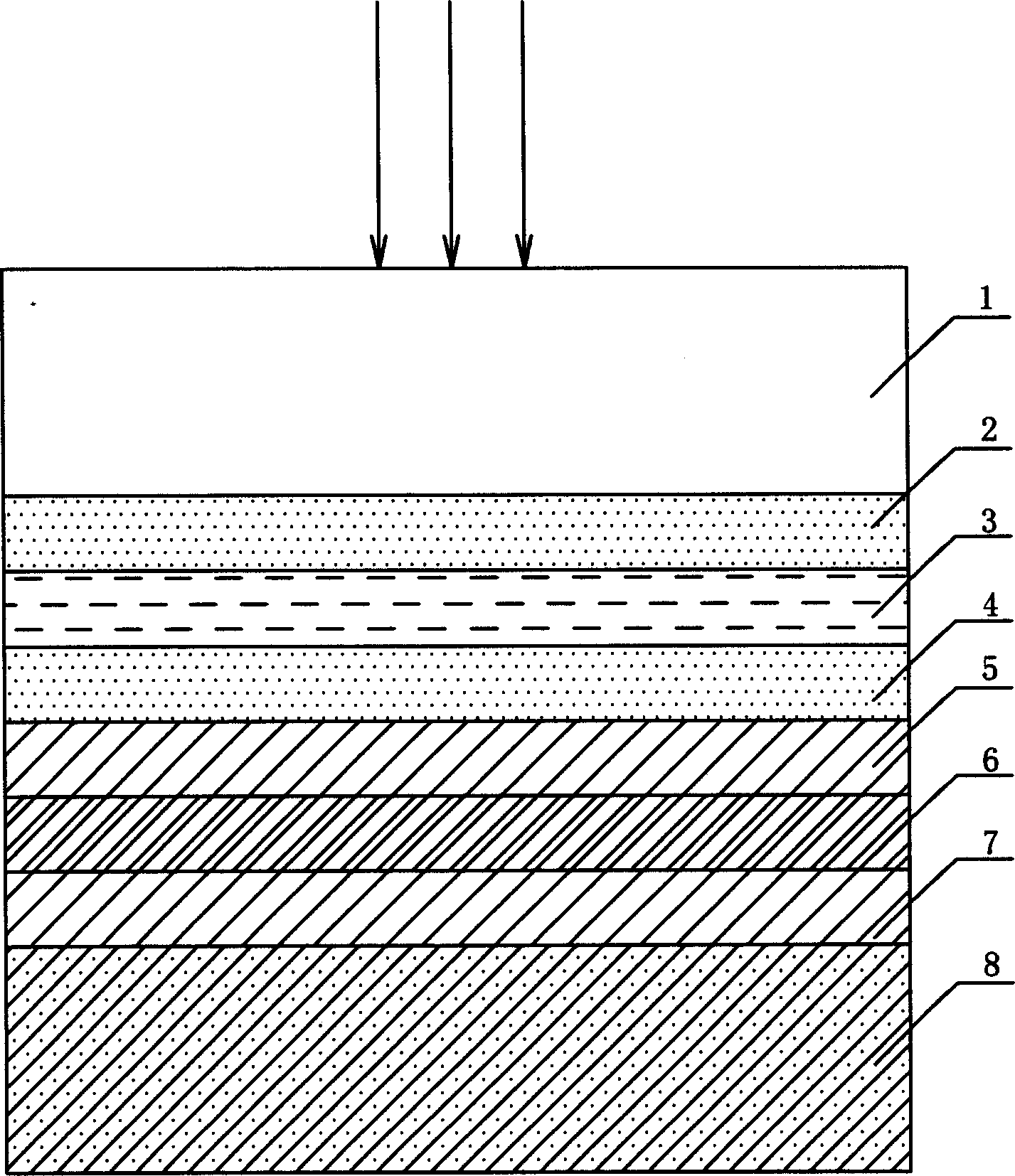

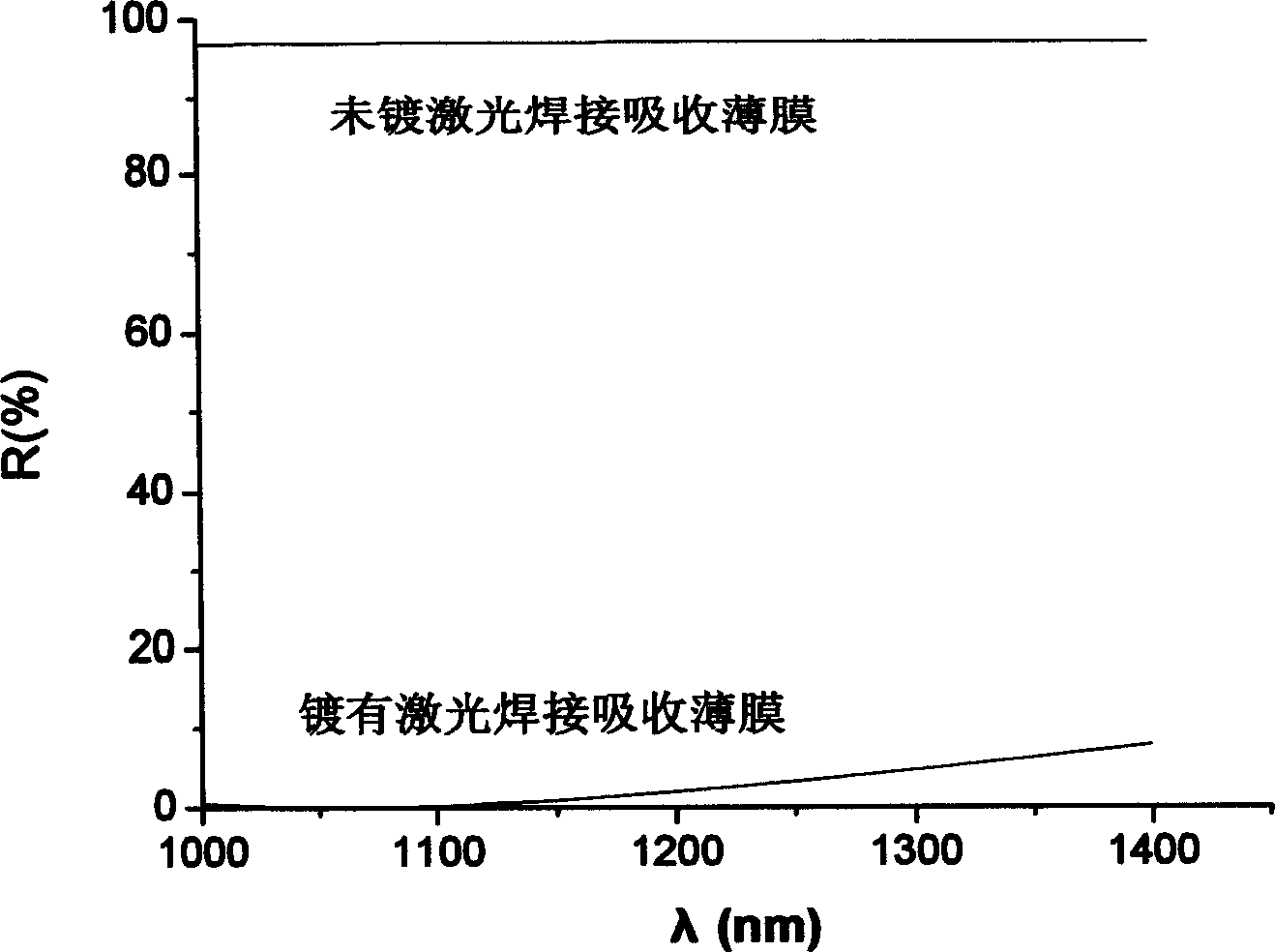

[0025] The transparent material (1) is glass, and the refractive index of glass is 1.53. The thickness of each layer of the laser welding absorbing film is as follows: the thickness of the first metal layer (2) is 19nm, the thickness of the medium layer (3) is 200nm, and the thickness of the second metal layer (4) is 60nm. The curve of its reflectivity changing with the incident laser wavelength is as follows: image 3 shown. When the incident material is glass, the curve of laser reflectivity changing with the thickness of the first metal layer is as follows Figure 4 shown.

Embodiment 2

[0027] The transparent material (1) is quartz, and the refractive index of quartz is 1.47. The thickness of each layer of the laser welding absorbing film is as follows: the thickness of the first metal layer (2) is 19nm, the thickness of the medium layer (3) is 200nm, and the thickness of the second metal layer (4) is 60nm. The curve of its reflectivity changing with the incident laser wavelength is as follows: Figure 5 shown. When the incident material is quartz, the curve of laser reflectivity changing with the thickness of the first metal layer is as follows Figure 6 shown.

Embodiment 3

[0029] The transparent material (1) is a lithium niobate crystal, and the refractive index of the lithium niobate crystal is 2.183. The thickness of each layer of the laser welding absorbing film is as follows: the thickness of the first metal layer (2) is 26nm, the thickness of the medium layer (3) is 200nm, and the thickness of the second metal layer (4) is 60nm. The curve of its reflectivity changing with the incident laser wavelength is as follows: Figure 7 shown. When the incident material is lithium niobate crystal, the curve of laser reflectivity changing with the thickness of the first metal layer is as follows Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com