Manufacturing method of packed magnetic metal nanometer carbon ball

A technology of magnetic metal nanometers and a manufacturing method, which is applied in the field of manufacturing high-purity filled magnetic metal nanocarbon spheres, and can solve the problems of being limited to a standstill state, unable to separate by magnetic force, and difficult to prepare filled magnetic metal nanocarbon spheres.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technology of the present invention is mainly to use pulse current (pulse current) to carry out arc discharge reaction under high-pressure inert gas (greater than 1 atmospheric pressure), and through this to change the electrode surface temperature, magnetic metal vapor density and carbon vapor density during arc discharge To improve the yield of carbon spheres, and for the fabrication of magnetic metal-filled nanocarbon spheres.

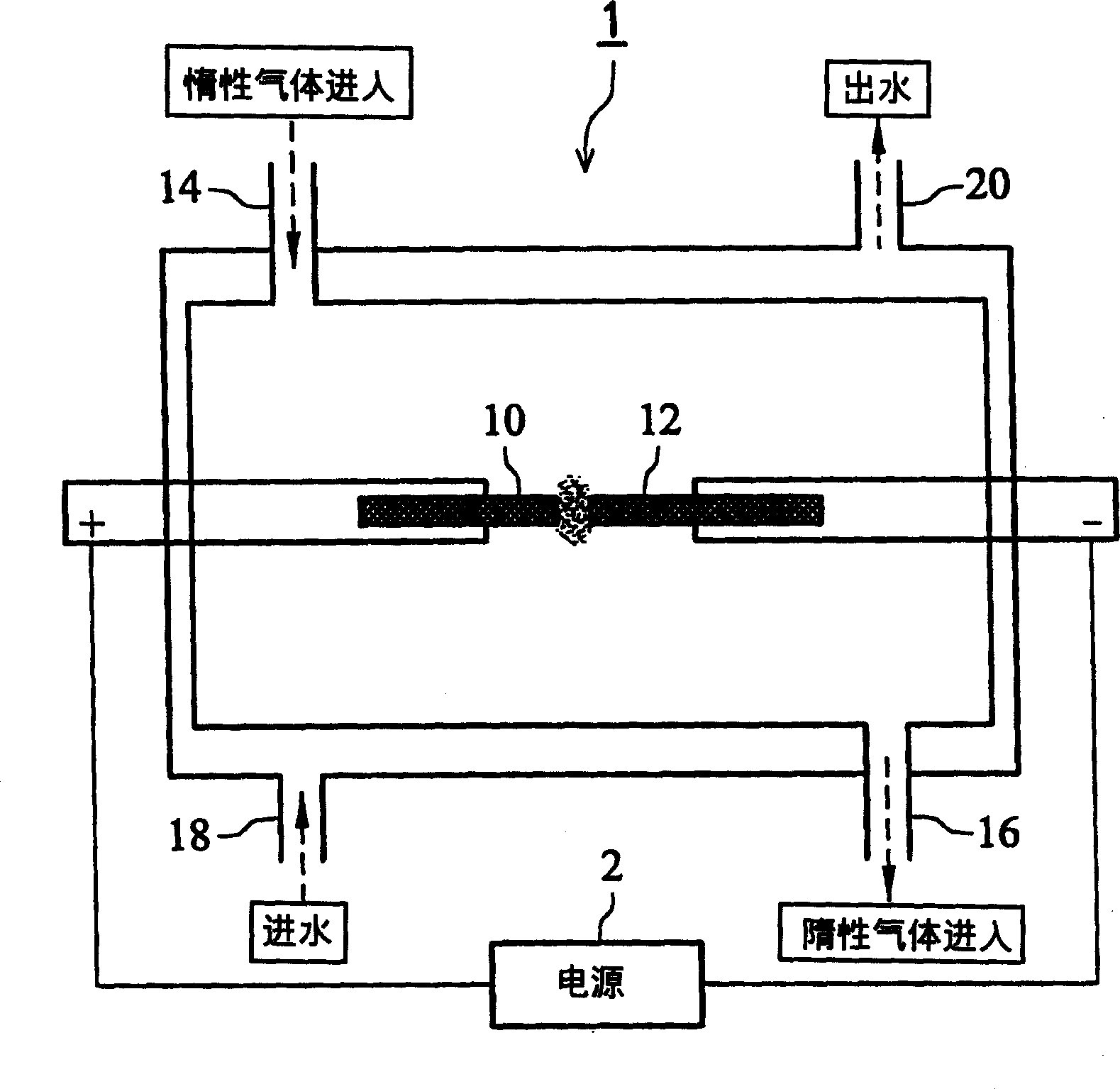

[0016] Please refer to figure 1 , figure 1 A schematic diagram of an arc reaction chamber useful in the practice of the invention is shown. In the arc reaction chamber 1 at least one pair of electrodes 10, 12 is included as an arc discharge. The inert gas enters the arc reaction chamber 1 through the inlet 12 and is discharged through the outlet 16 . The periphery of the arc reaction chamber 1 is surrounded by flowing cooling water. In the figure, 16 is the cooling water inlet, and 18 is the cooling water outlet.

[0017] In the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com