Glass substrate and glass cutting method

A glass substrate and glass cutting technology, applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve the problems of small cracks and broken glass, disadvantages, etc., achieve light weight, increase productivity and yield, and increase strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the glass substrate and glass cutting method of the present invention, and comparative examples based on the embodiments will be described in detail below with reference to the accompanying drawings. In the following embodiments, a case where the present invention is applied to a glass substrate of a portable terminal equipped with a touch panel, and a cutting method for obtaining such a glass substrate will be described. However, it is obvious that various changes and modifications can be made unless the invention departs from the scope of the present invention.

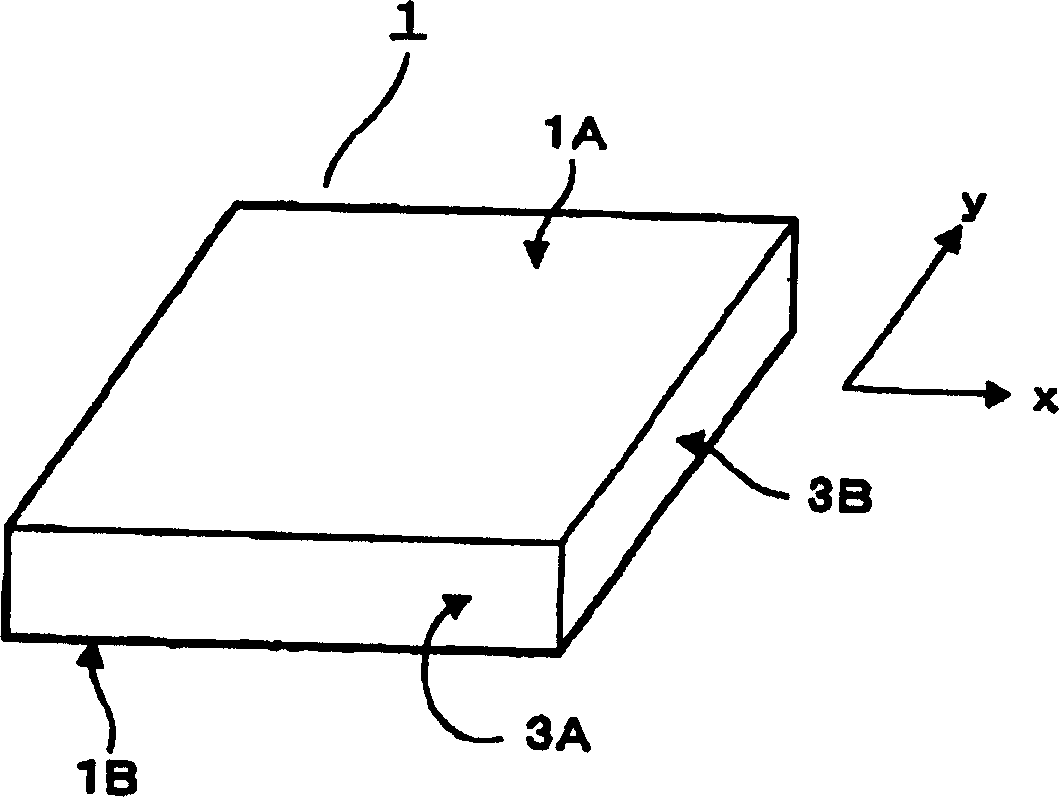

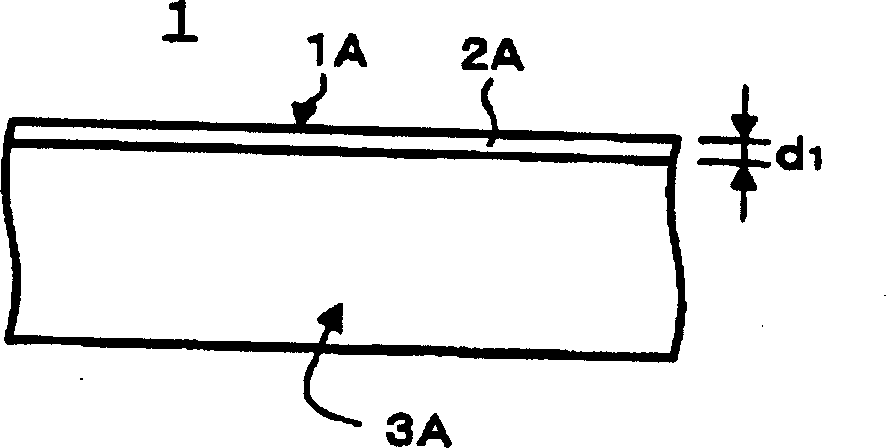

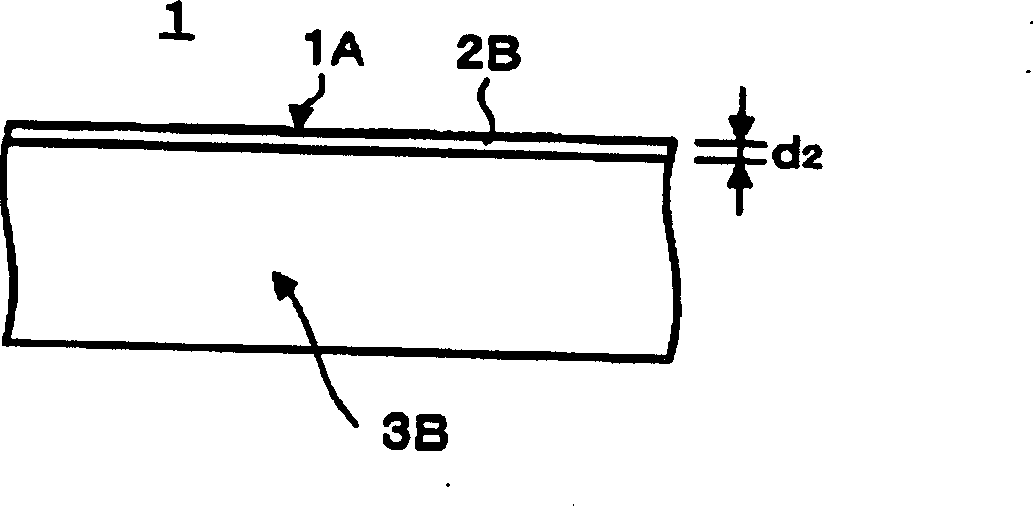

[0047] exist Figures 1A to 1D In , a schematic structure of a glass substrate based on the structure of the present invention is shown. In addition to Na, K and SiO 2 In addition to the so-called soda glass, non-alkali glass can also be used as the material of the glass substrate 1 .

[0048] Such as Figure 1A As shown, a glass substrate 1 has a first major surface 1A and a second major s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com