Method for determining fusion mugget area of resistance spot welding for allautal through technique of syncretizing multiple informations

An aluminum alloy plate and multi-information fusion technology, which is applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of irregular shape of nugget, insufficient reflection of nugget changes, measurement errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

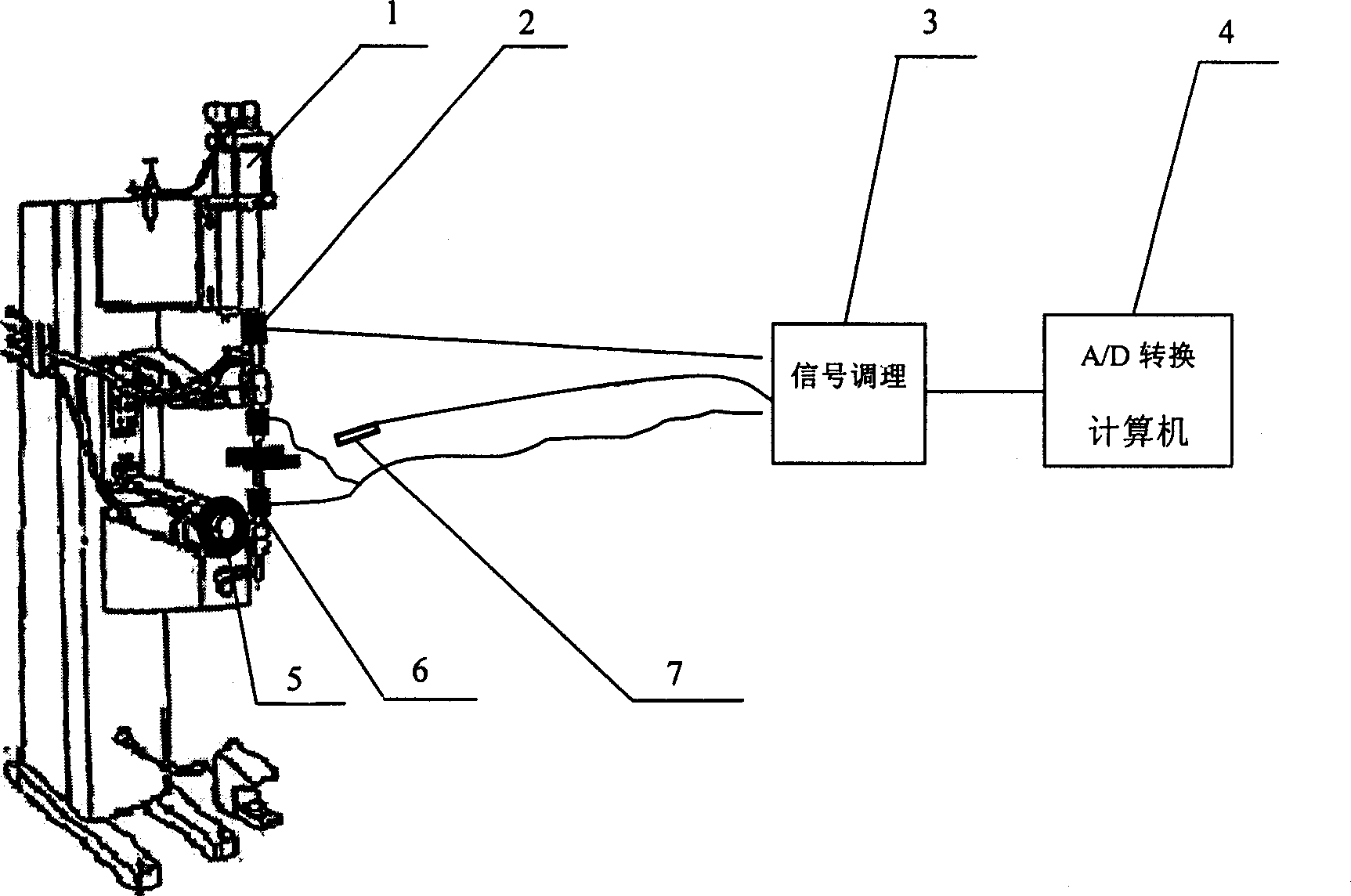

[0026] Aluminum alloy resistance spot welding nugget area detection device: it includes two parts: data acquisition system (including sensor, signal conversion circuit) and computer, its function is to detect current, voltage, displacement and sound related to quality during spot welding signal parameters, and analyze and process the detection parameters to obtain the area of the nugget. The device can detect 4 different types of physical quantities at the same time, so there are 4 measurement channels.

[0027] Voltage measurement channel: it is composed of two electrode clips directly clamped on the electrodes of the spot welding machine, a voltage conversion circuit (output 0~5V) and a shielded cable. It transmits the voltage value output by the conversion circuit to a high-speed data acquisition card ( ADLINK DAQ2010 four-channel, synchronous, 2M / s).

[0028] Current measurement channel: it is composed of a current sensor-inductive collar (measurement range 500A~99,000A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com