Appts for cleaning edges of wafers

A wafer and edge technology, applied in the field of wafer cleaning devices, can solve problems such as damage, reduced wafer productivity, and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

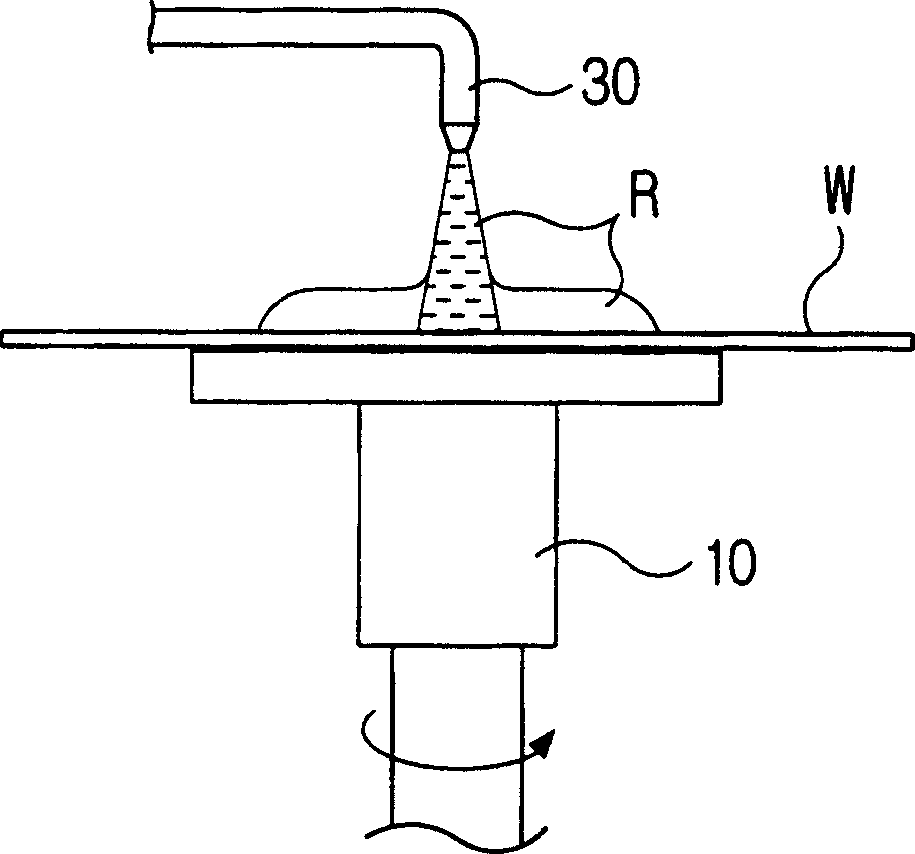

[0035] image 3 It is a schematic diagram of cleaning the edge of the wafer by the dry cleaning process using dry ice of the present invention.

[0036] Such as image 3 As shown, the device for cleaning the edge of the wafer of the present invention is arranged on a side portion of a wafer (W) held by suction by a rotary chuck 10, and the device for cleaning the edge of the wafer includes a jet of solidified carbon dioxide CO that is converted into particles. 2 (referred to as dry ice) nozzle body 1, and a nozzle body holder 2 that moves the nozzle body 1 between a rest position and a cleaning position. The nozzle body holder 2 (referred to below as a pneumatic cylinder) is shown in the figures as a pneumatic cylinder, but may include a stepper motor. The nozzle body 1 has a lower bracket 5 connected to the piston 4 of the pneumatic cylinder 2, which is mounted to the cleaning device via a bracket 6 arranged on the side part of the rotary chuck 10.

[0037] When the spin c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com