Manufacturing process and installation for the thin bolt with spanner pilot hole and hexangular socket head

A manufacturing method and technology of guide holes, which are applied in the field of screw manufacturing, can solve problems such as the deviation of the drill axis of the drill bit, the angle of the edge trimming of the drill lip is not correct, and the reduction of the use effect, so as to shorten the working time, reduce defective products, The effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

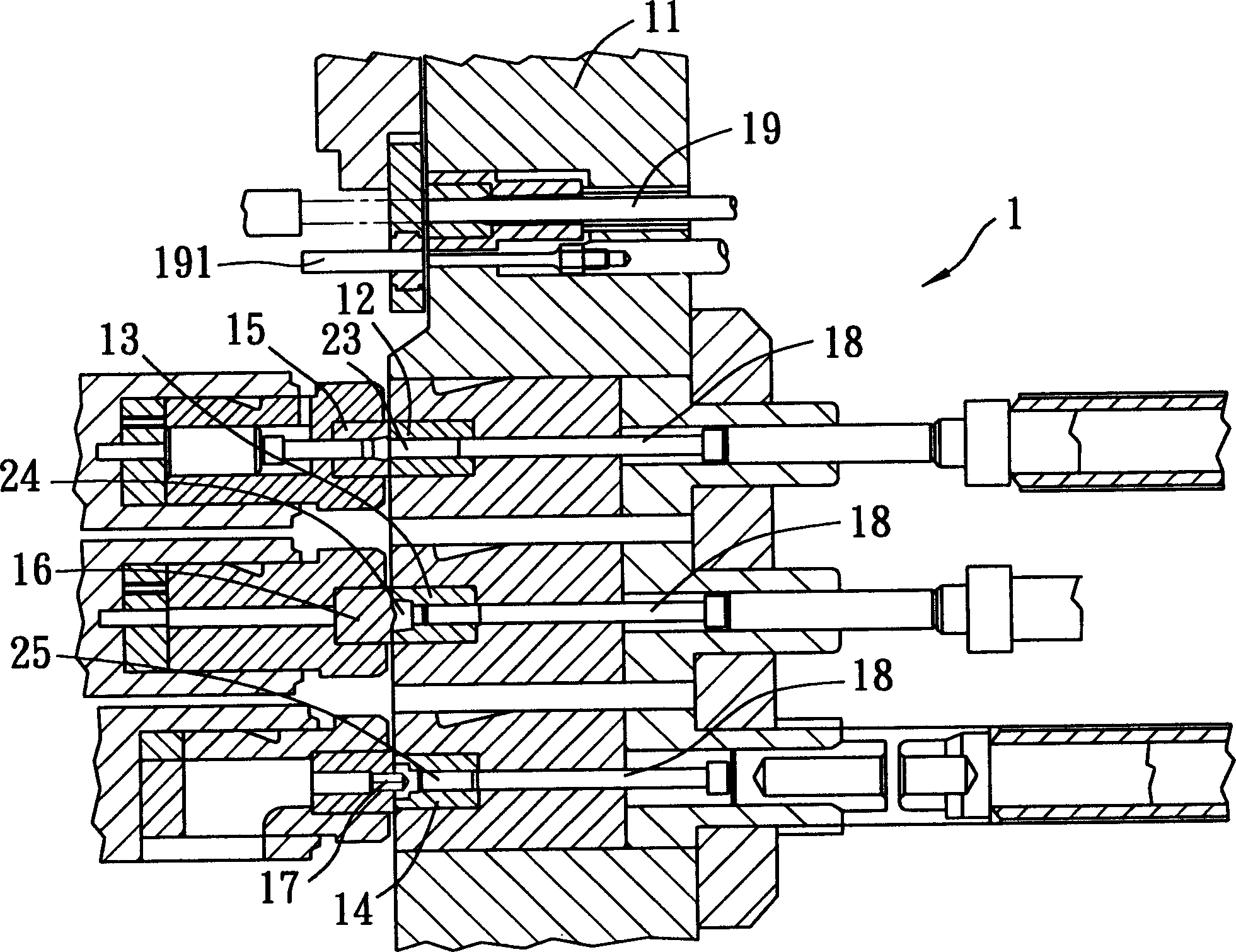

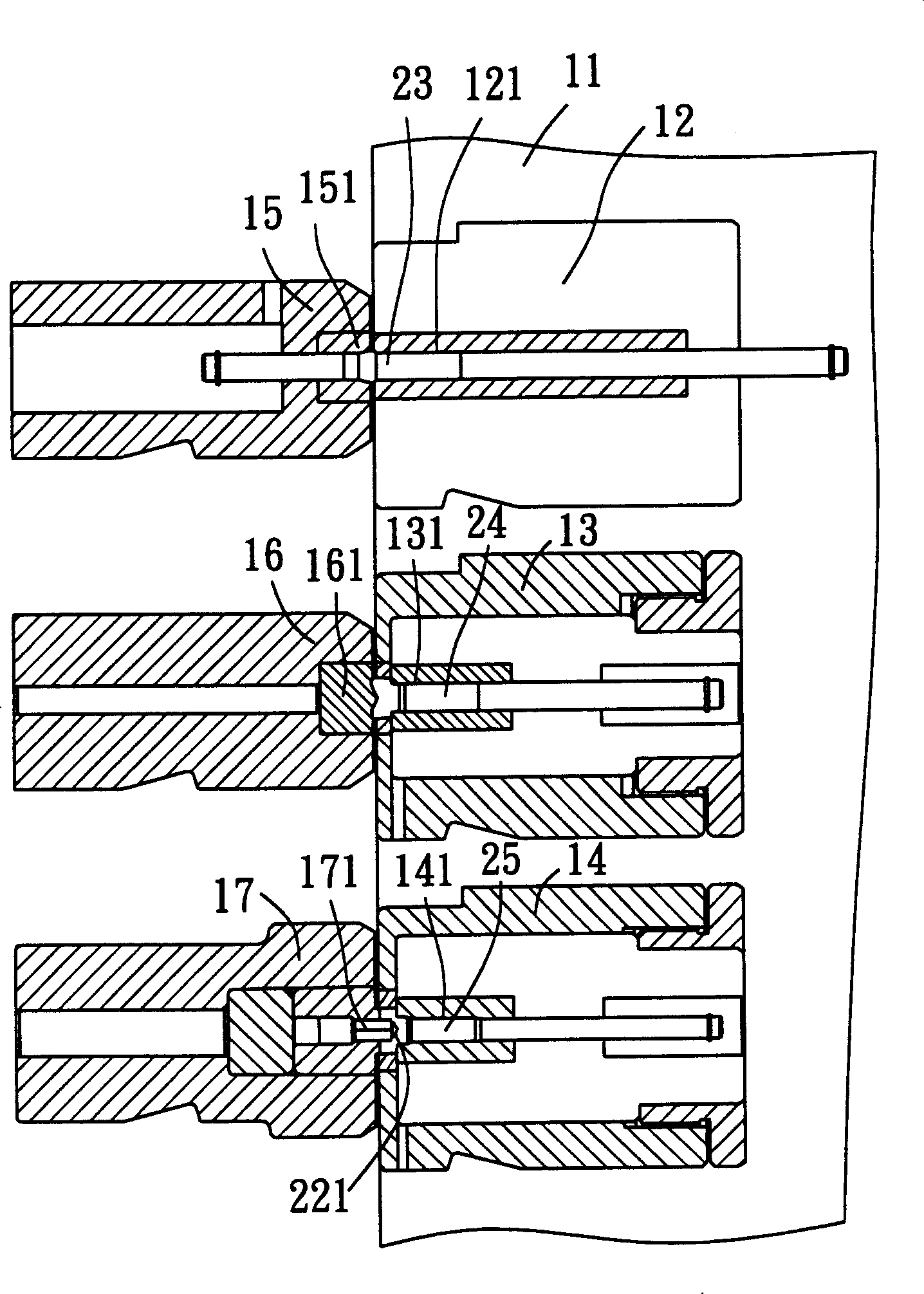

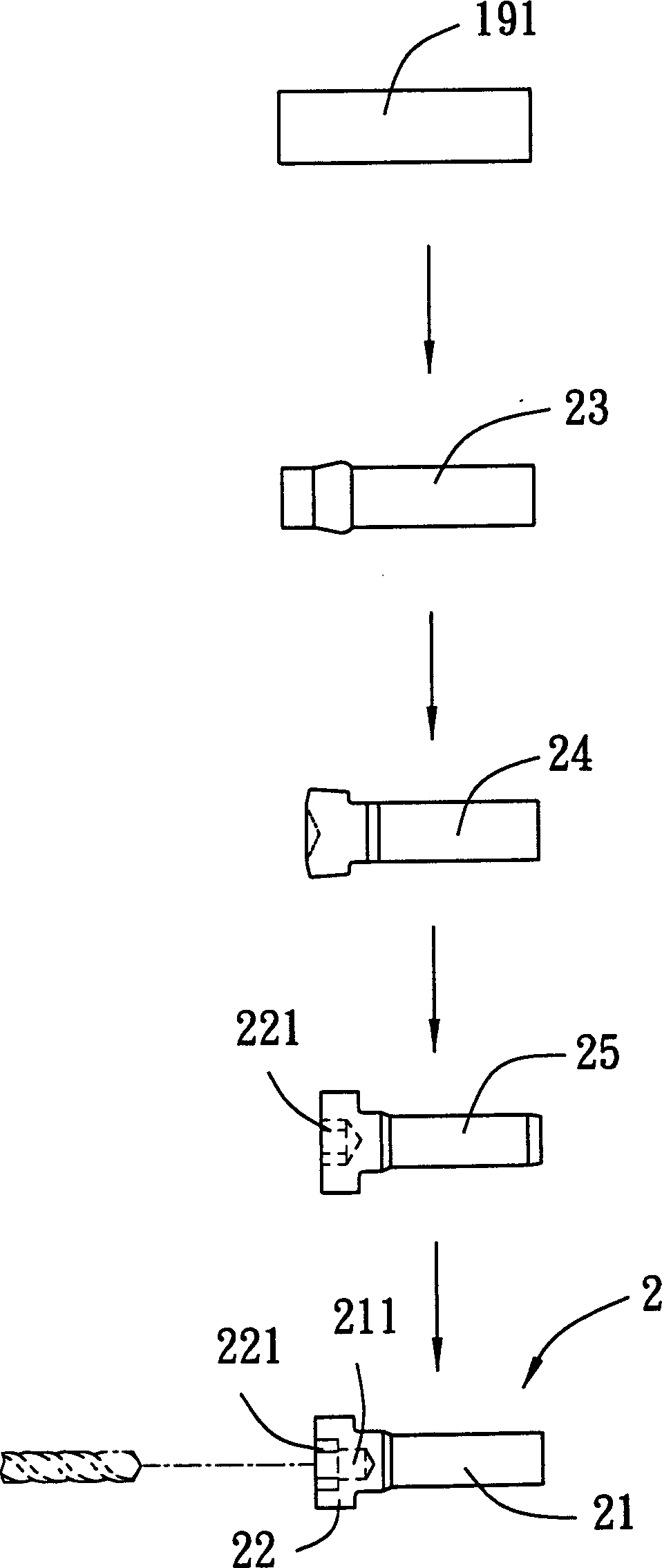

[0031] Such as Figure 5 , Image 6 and Figure 7 As shown, the first preferred embodiment of a screw manufacturing device of the present invention comprises a machine platform 3, a first female mold 41, a second female mold 42, A third female mold 43 and a fourth female mold 44, and a first male correspondingly positioned in front of the female molds 41-44 and driven by a power source to punch back and forth relative to the female molds 41-44 Die 51, a second male die 52, a third male die 53 and a fourth male die 54. As for other devices and actions of the screw manufacturing device, it is the same as in the past and will not be repeated. The above-mentioned male dies 51-54 must be matched with the corresponding female dies 41-44 to sequentially define die cavities of a predetermined shape, and forge and form the screws of the required shape. Therefore, in the following description, they are respectively The female die and the corresponding male die are described sequenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com