Aqueous injection of curcuma oil extract and preparation process and use

A technology of turmeric oil and extract, which is applied in the field of injection water, and can solve the problems of storage stability and insufficient anticancer activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] Preferred embodiments of the invention are highly summarized as follows:

[0036] 1. Turmeric oil extract water injection, which is prepared as a raw material with turmeric oil extract containing active ingredients, a surfactant and an aqueous medium, the turmeric oil extract containing active ingredients is separated from turmeric oil and includes as At least about 25 wt% of the aromatic curcumone in the active ingredient, the surfactant is a medicinal non-ionic surfactant, and the concentration of the aromatic curcumone in the aqueous injection is 0.02-4 wt%.

[0037] 2. The aqueous preparation for injection according to item 1, wherein the active ingredient-containing turmeric oil extract includes at least about 30 wt% of aromatic curcumone as an active ingredient.

[0038] 3. The aqueous injection according to item 1, wherein the active ingredient-containing turmeric oil extract comprises at least about 45wt% aromatic curcumone as an active ingredient, or preferably...

preparation example 1

[0061] Preparation method of turmeric oil extract (sesquiterpene ketones)

[0062] With 1000ml of turmeric volatile oil (the content of aromatic curcumone, curcumone and aromatic curcumone derivatives ≥ 15wt%) as raw material, it is refined through the MD-S80 molecular distillation apparatus of Guangzhou Hanwei Electromechanical Co., Ltd., and its process conditions: distillation temperature 35 ~45℃, distillation pressure 70~90Pa, scraping film speed 300-320 rpm, condensing surface temperature 20~25℃, system heat preservation 20~25℃, material flow rate 15~30ml / hour, distillate is obtained, only Collect the distillate, accumulate to a sufficient amount (about 450ml), and continue molecular distillation. The distillation temperature is 45-60°C, the distillation pressure is 30-70Pa, the scraping film speed is 300-320 rpm, the condensation surface temperature is 20-25°C, the system is kept warm at 20-25°C, and the flow rate of the fraction is 15-30ml / hour. 150ml of distillate and...

preparation example 2

[0063] Preparation example 2: using the same raw material as in the preparation example, i.e. turmeric volatile oil, according to the same method in the preparation example 1, only the peak of aromatic curcumone is cut off, and the turmeric oil containing about 95.5wt% aromatic curcumone is obtained Extract. In order to prepare western medicine injections, the turmeric oil extract of Preparation Example 2 can be used, and the preparation method of the injections is exactly the same as in the following examples.

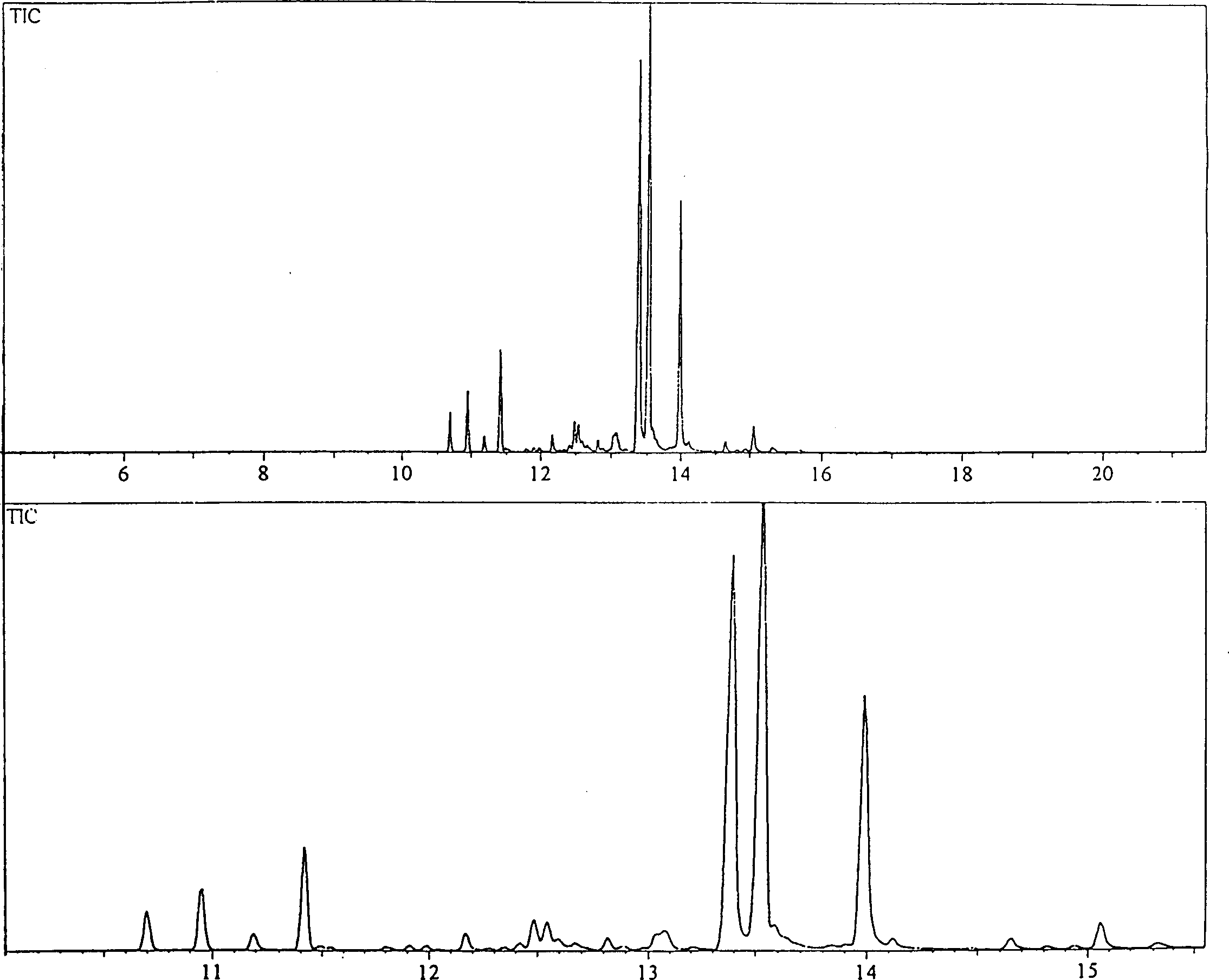

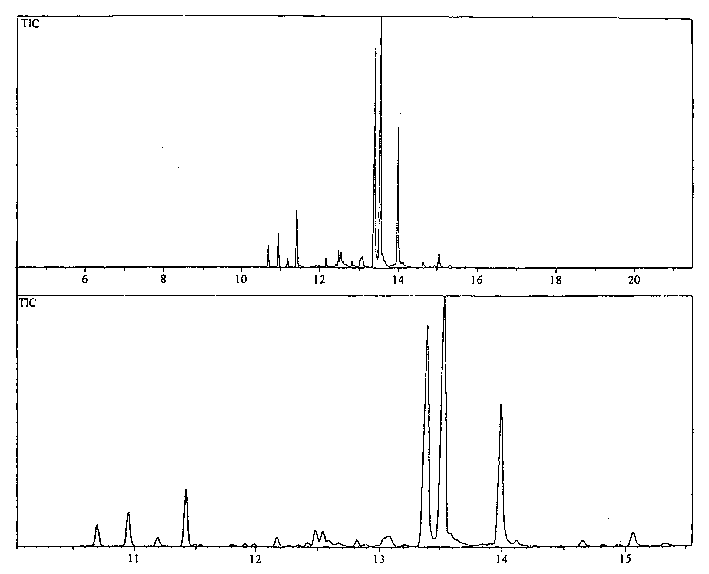

[0064] in the attached figure 1 The fingerprint spectrum of the turmeric oil extract of Preparation Example 1 is given in. in the attached figure 2 The fingerprint spectrum of the turmeric oil extract of Preparation Example 1 stored in the presence of air for 3 months is given in . Wherein the capillary chromatography stationary liquid name: polydimethylsiloxane or poly(5% phenyl) dimethylsiloxane, commercial column name DB1, DB-5 or BP5 etc. The change in peak h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com