Method for preparing 1-ethene under ethene oligomerizating catalyst system

An ethylene oligomerization and catalyst technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of high local temperature, uneven mass and heat transfer, catalyst deactivation, etc., to achieve uniform mixing, Good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

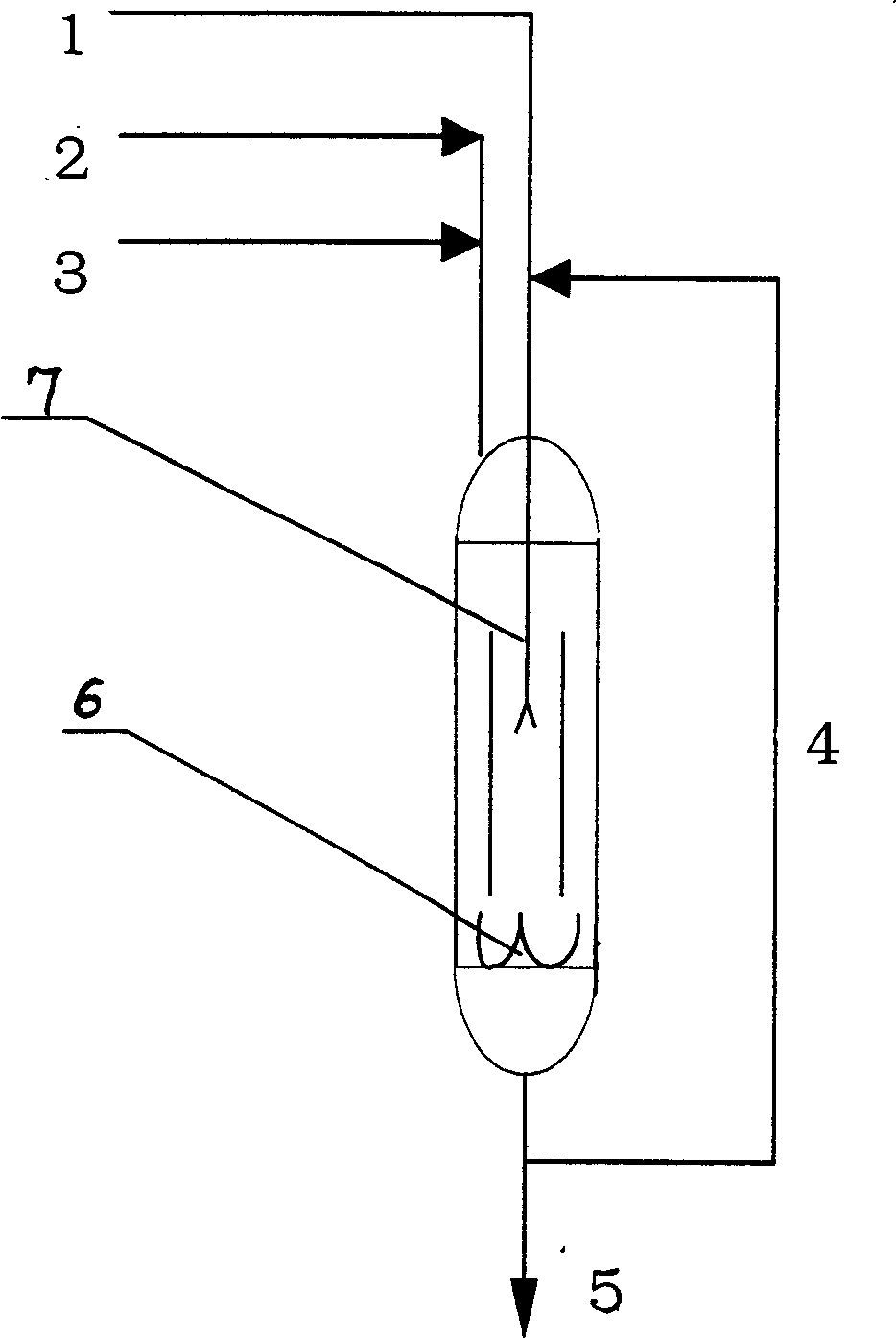

[0032] An ethylene feed pipe (1) is installed on the top of the reactor, at least one nozzle (7) is installed at the inner end of the feed pipe reactor, a solvent (2) and a catalyst (3) mixing feed pipe are installed, and a nozzle is placed at the outlet end of the reactor. The baffle (6) and the outlet are respectively connected with the separation device (5) and the feed pipe (4). After cleaning the reactor with n-heptane, vacuum-dry it at 100°C for 1 hour, cool to room temperature, replace it with ethylene, open the ethylene inlet valve, keep the pressure in the reactor at 5.0Mpa, and feed the solvent at a certain flow rate. Catalyst pyrrole derivative (b) and alkylaluminum (c) and improver (d) component, chromium compound (a) component, open the circulation pump and cooler, make the jet loop effect in the reactor, keep the reactor The internal temperature was maintained at 115°C, and the outlet valve of the reactor was opened to allow the reaction liquid to enter the separ...

Embodiment 2-7

[0034] The process conditions and results are shown in Table 1.

[0035] Reality

[0036] Catalyst a

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com