Biological sensor and testing method therewith

A technology of a biosensor and a measurement method, which is applied in the field of biosensors and the measurement using the biosensor, can solve the problems of inability to perform simultaneous measurement, inability to measure, and decrease in measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

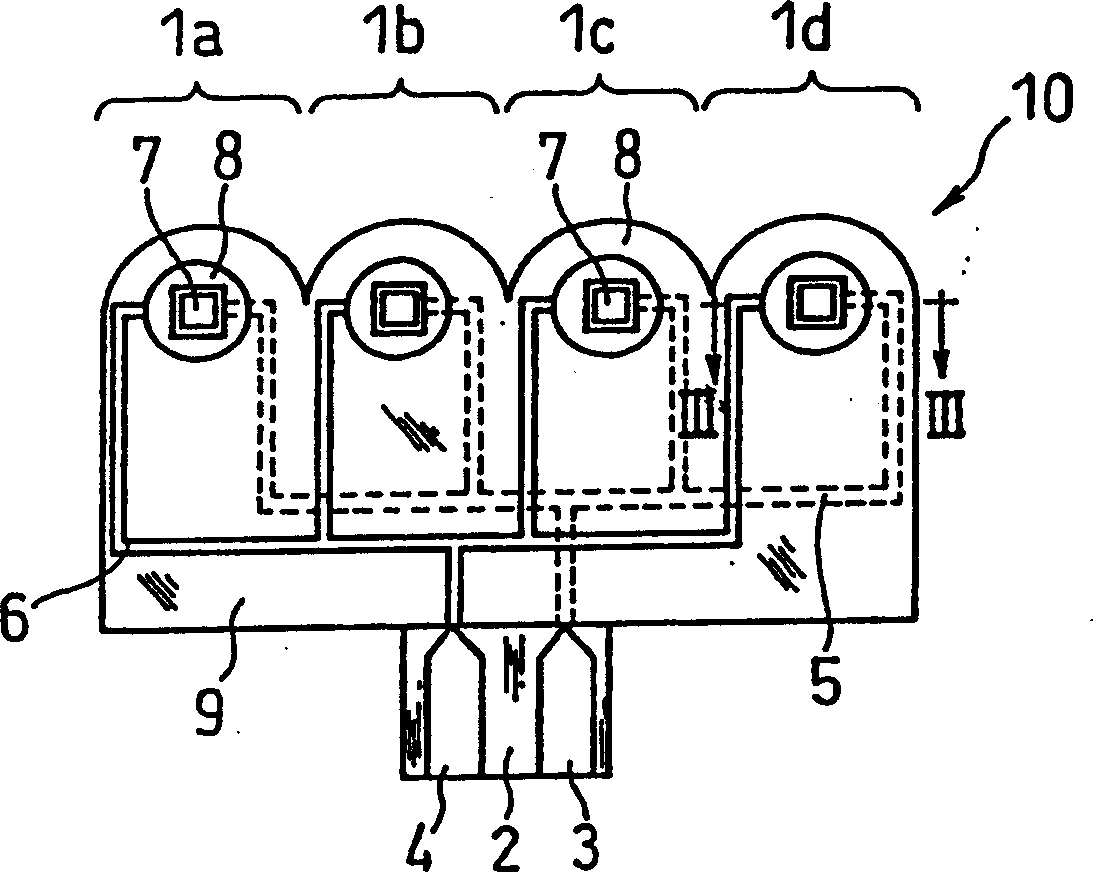

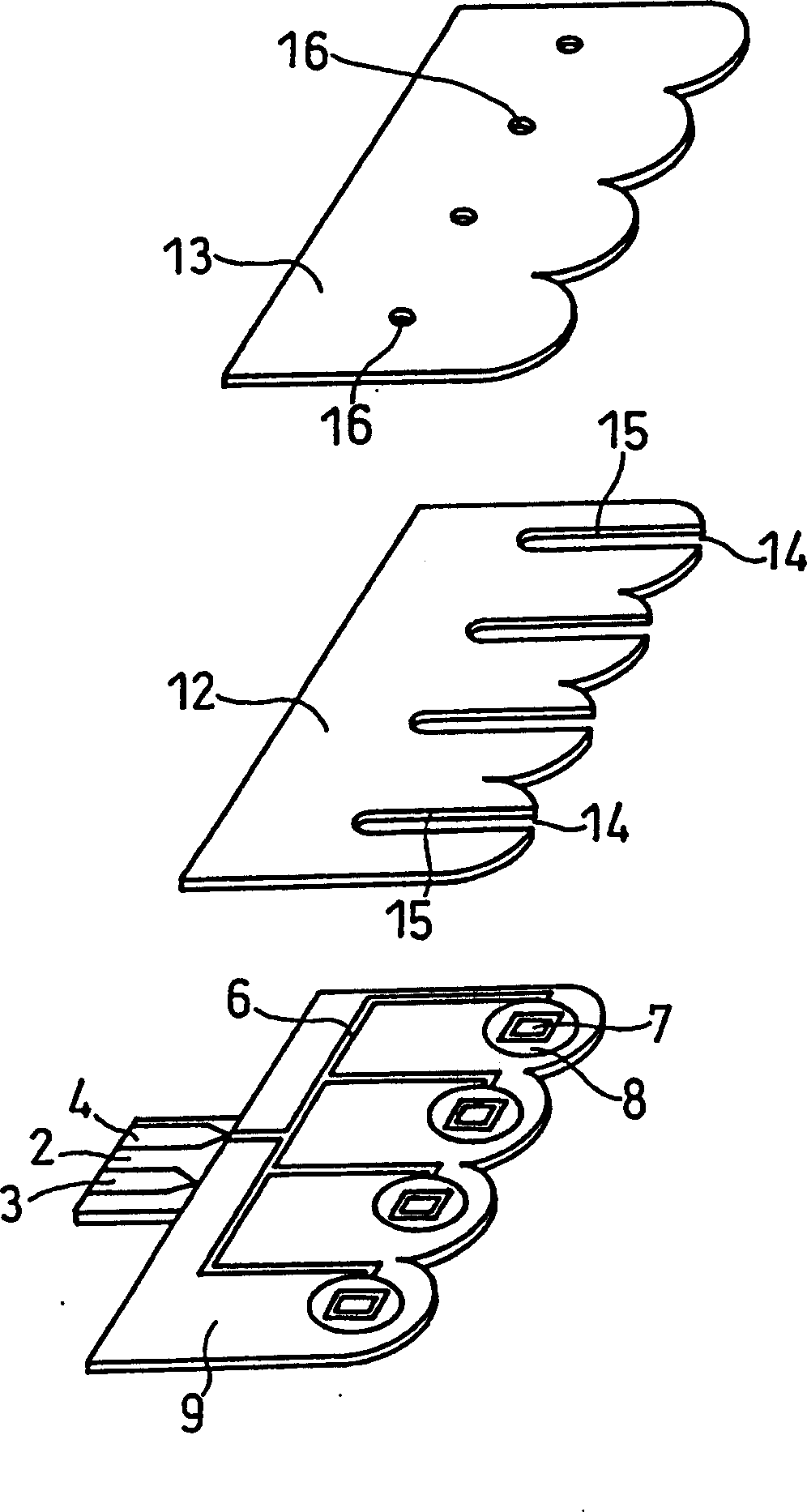

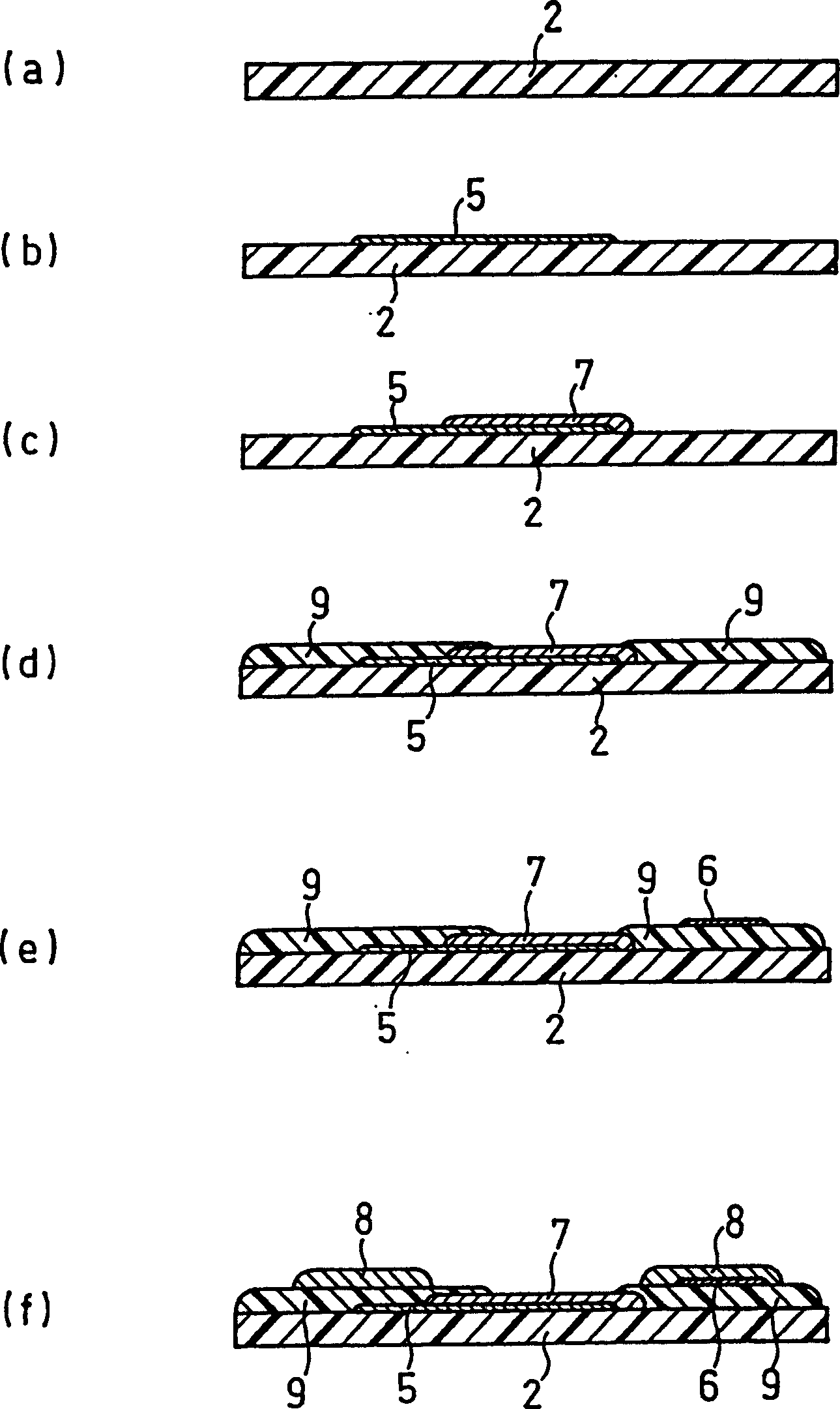

[0063] figure 1 It is a top view of the biosensor according to Embodiment 1 of the present invention, with the separator and cover removed. figure 2 It is an exploded perspective view of the same biosensor without the reagent unit and the control unit. image 3 is the edge indicating the formation process of the electrode system part figure 1 Sectional view of the III-III line cut. Figure 4 is along figure 1 Cross-sectional view of a III-III line cut biosensor comprising a reagent part and a control part.

[0064] The production method of the biosensor 10 of this embodiment is as follows. First, a silver paste is applied by screen printing on a substrate 2 made of an insulating resin to form a measuring pole terminal 3 and a measuring pole lead wire 5 ( image 3 (b)). Next, apply a conductive carbon paste containing a resin binder to form the measuring electrode 7 ( image 3 (c)). Then apply insulating paste to form insulating layer 9 ( image 3 (d)). Apply silver ...

Embodiment approach 2

[0079] Figure 5 It is a top view of the biosensor according to Embodiment 2 of the present invention, with the separator and cover removed. Figure 6 It is an exploded perspective view of the same biosensor without the reagent unit and the control unit. Figure 7 Indicates the formation process of the electrode system part Figure 5 Sectional view of line VII-VII. Figure 8 is along Figure 5 Cross-sectional view of a biosensor comprising a reagent part and a control part cut by line VII-VII.

[0080] The production method of the biosensor 20 of this embodiment is as follows. First, on the substrate 22 made of insulating resin, silver paste is applied by screen printing method to form the terminal 23 for the measuring pole, the terminal 24 for the matching pole, the lead wire 25 for the measuring pole and the lead wire 26 for the matching pole ( Figure 7 (a)). Next, apply a conductive carbon paste containing a resin binder to form the measuring electrode 27 ( Figure ...

Embodiment approach 3

[0090] Figure 13 It is a plan view of the biosensor according to Embodiment 3, with the separator and cover removed. Figure 14 It is an exploded perspective view of the same biosensor without the reagent unit and the control unit.

[0091] The same as the manufacturing method of Embodiment 1, the substrate 52 of the biosensor 50 of this embodiment is formed with terminals 53 for measuring electrodes, lead wires 55 for measuring electrodes, measuring electrodes 57, insulating layer 59, terminals 54 for matching electrodes, and electrodes for matching electrodes. With wire 56 and matching pole 58. Next, a reagent portion is formed on the electrode system. The partition plate 62 used in the present embodiment has slits 65a, 65b, 65c, and 65d of different lengths for forming the sample solution supply channels of the respective sensor units, and these slits are connected to form the sample solution supply channel indicated by 64. An open portion of the mouth. The spacer 62 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com