Microcapsule clomazone weed killer composition and its preparing process

A technology of microencapsulation and clomazone, applied in botany equipment and methods, biocides, animal repellants, etc., can solve problems such as herbicide restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

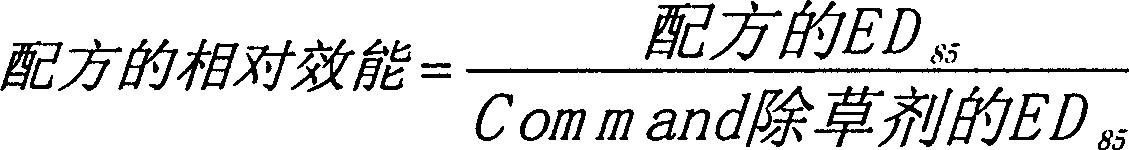

Method used

Image

Examples

Embodiment 1

[0015] Preparation of 0.15 kg / L (1.5 lb / gal) Capsule Suspension (1.5CS) Formulation (Formulation A)

[0016] By stirring, an appropriate amount of polyvinyl alcohol and water can be stirred at 80-90 ° C for 1 hour to obtain a stock solution of 20% (w / w) partially hydrolyzed polyvinyl alcohol with an average molecular weight of 13,000 to 23,000 (Airvol 203). Store the cooled solution for later use.

[0017] Put 20.0 grams of the 20% polyvinyl alcohol aqueous solution prepared above, 1.8 grams of 100% polydimethylsiloxane antifoam base (Dow Corning 1500), 15.0 grams of 2% xanthan gum aqueous solution (Kelzan M) and 400.0 grams of water. The mixture was mixed at high speed in a high shear mixer for 20 seconds before adding premixed 140.0 g of clomazone, 30.0 g of polymethylene polyisocyanate phenyl (PMIPP, Mondur MR) and 30.0 grams of white spirit (C 9 -C 15 Aromatic, naphthalene-depleted hydrocarbon, flash point 95°C, Armoatic 200ND) solution, the mixture was emuls...

Embodiment 2

[0020] Large-Scale Preparation of 0.2 kg / L (2.0 lb / gal) Clamazone Capsule Suspension (2.0CS) Formulation (Formulation E-1)

[0021] Put 2.38kg (5.24 pounds) 20% polyvinyl alcohol (Airvol 203), 2.38kg (2.38 pounds) 20% polydimethylsiloxane antifoam agent (DowCorning) into a 227 liter (500 gallon) stainless steel kettle 1500) in water and 0.095 kg (0.21 lbs) xanthan gum viscosity modifier / stabilizer (Kelzan M) A solution in 129.03 kg (284.20 lbs) of water and stirred at 80°C for one hour. The solution was then cooled to 20°C and placed in a 36.32 liter (80 gallon) batch homogenizer. With the homogenizer running, add premixed 73.25 kg (161.34 lbs) of clomazone, 15.78 kg (34.75 lbs) of polymethylene polyisocyanate to the homogenizer by gravity within 15-90 seconds Ester (PMIPP, Mondur MR) and 15.78kg (34.75 lbs) of white spirit (C 9 -C 15 Aromatic mixture, flash point is 95°C, Armoatic200) solution. The mixture was homogenized for 2-3 minutes. After homogenization was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com