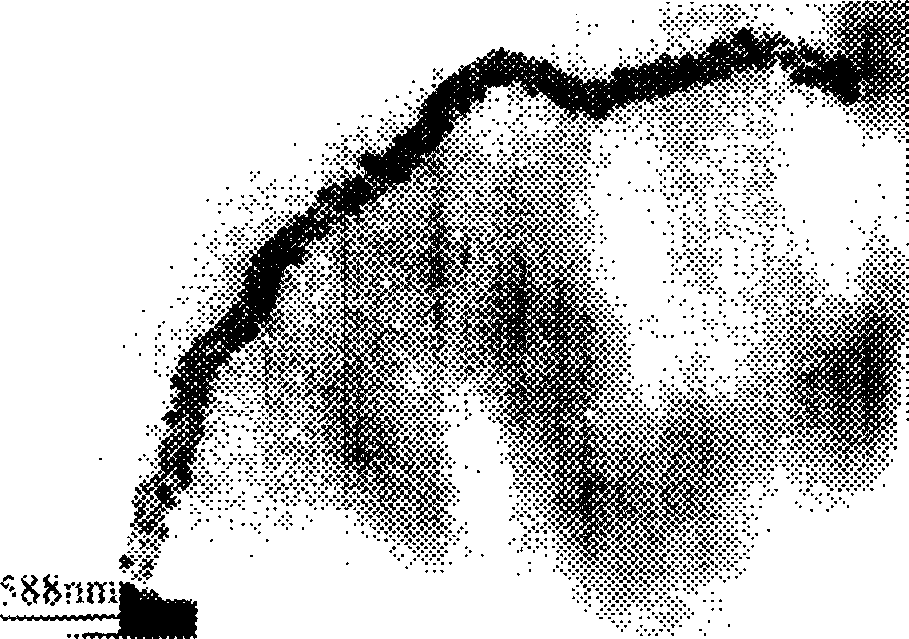

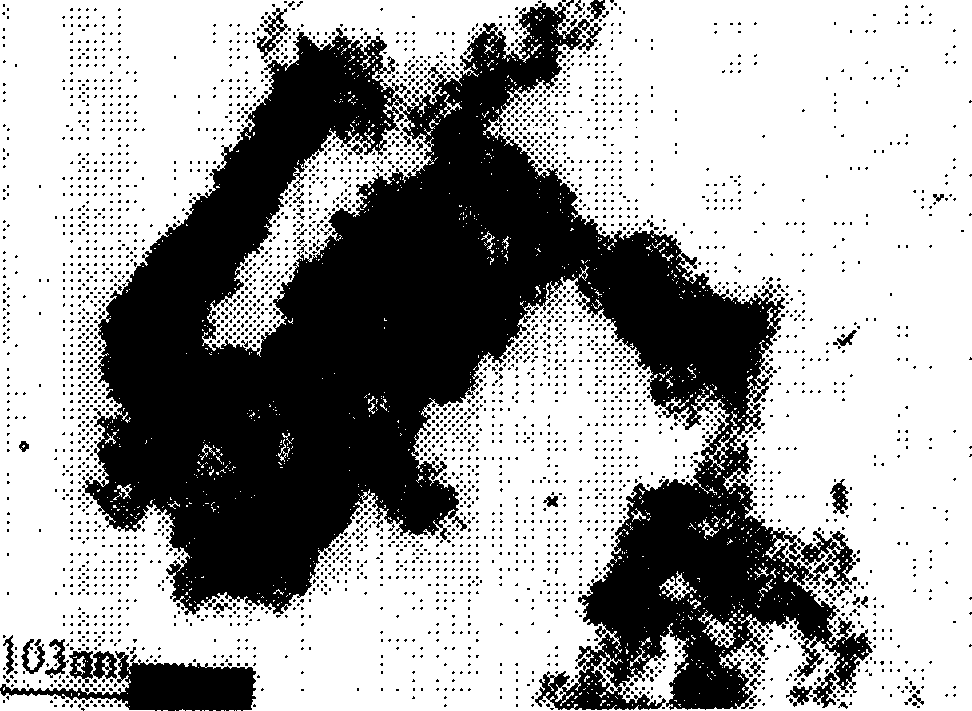

Preparation method of carbon nano-pipe/silver complix functional material

A carbon nanotube and composite function technology, which is applied in the field of preparation of carbon nanotube/silver composite functional materials, can solve the problems of affecting the performance of composite materials, carbon nanotubes are inactive, and the metal body has poor adhesion, and achieves good dispersibility, The effect of high product purity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1). Disperse 1.0 gram of carbon nanotubes in 1 liter of acetone under stirring to obtain a suspension containing carbon nanotubes;

[0040](2). Preparation of silver nitrate aqueous solution, adding ammonia to make it a complex solution, the concentration of silver nitrate in the complex solution is 0.08mol / L, and the concentration of ammonia is 0.16mol / L, the complex solution is added to the step ( 1) in the suspension, the volume ratio of the suspension to the complex solution is 1:0.1, and the silver ammonium ions are adsorbed at room temperature for 26 hours, and centrifuged and washed to obtain carbon nanotubes adsorbed with silver ammonium ions;

[0041] (3). The carbon nanotubes that are adsorbed with silver ammine ions obtained in step (2) are dispersed in acetone, and its concentration in acetone is 1.0g / L; then add sodium citrate solution in this dispersion, Make the concentration of the mixed sodium citrate solution 0.2mol / L, stir at 25°C for 2 hours to obta...

Embodiment 2

[0043] (1). Disperse 0.5 gram of carbon nanotubes into 1 liter of absolute ethanol under stirring to obtain a suspension containing carbon nanotubes;

[0044] (2). Preparation of silver nitrate aqueous solution, adding ammonia to make it a complex solution, the concentration of silver nitrate in the complex solution is 0.005mol / L, and the concentration of ammonia is 0.01mol / L, the complex solution is added to the step ( 1) in the suspension, the volume ratio of the suspension to the complexing solution is 1:1, and the silver ammonium ions are adsorbed at room temperature for 48 hours, and centrifuged and washed three times to obtain carbon nanotubes adsorbed with silver ammonium ions;

[0045] (3). The carbon nanotubes adsorbed with silver ammonium ions obtained in step (2) are dispersed in dehydrated alcohol, and its concentration in dehydrated alcohol is 0.5g / L; Hydrazine solution, make the concentration of the mixed hydrazine hydrate solution 0.01mol / L, react at 35°C for 1 ...

Embodiment 3

[0047] (1). Disperse 10 grams of carbon nanotubes in 1 liter of absolute ethanol under ultrasound to obtain a suspension containing carbon nanotubes;

[0048] (2). Preparation of silver nitrate aqueous solution, adding ammonia to make it a complex solution, the concentration of silver nitrate in the complex solution is 0.01mol / L, and the concentration of ammonia is 0.02mol / L, the complex solution is added to the step ( 1) in the suspension, the volume ratio of the suspension to the complexing solution is 1:5, and the silver ammine ions are adsorbed at 50° C. for 2 hours, and centrifuged and washed three times to obtain carbon nanotubes adsorbed with silver ammine ions;

[0049] (3). The carbon nanotubes adsorbed with silver ammonium ions obtained in step (2) are dispersed in dehydrated alcohol, and its concentration in dehydrated alcohol is 10g / L; then add triethanolamine in this dispersion solution, the concentration of the mixed triethanolamine solution was 1.2 mol / L, reacte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com