Semiconductor laser device and solid laser device using same

A laser device and semiconductor technology, which is applied in the direction of semiconductor laser devices, semiconductor laser optical devices, semiconductor lasers, etc., can solve the problems that the end face excitation method of excitation efficiency cannot be used, and the parallel component is difficult to focus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be specifically described below according to the accompanying drawings.

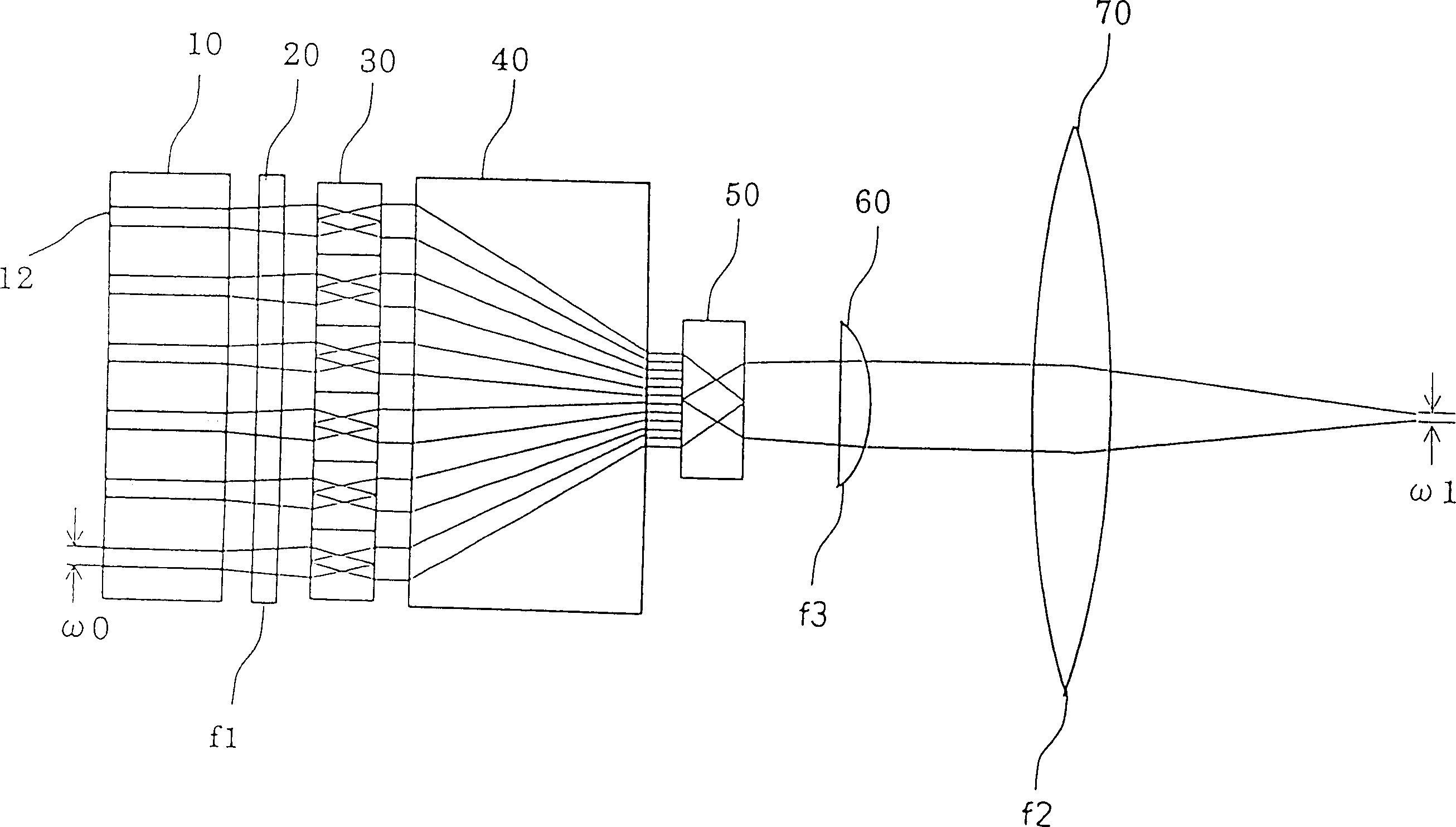

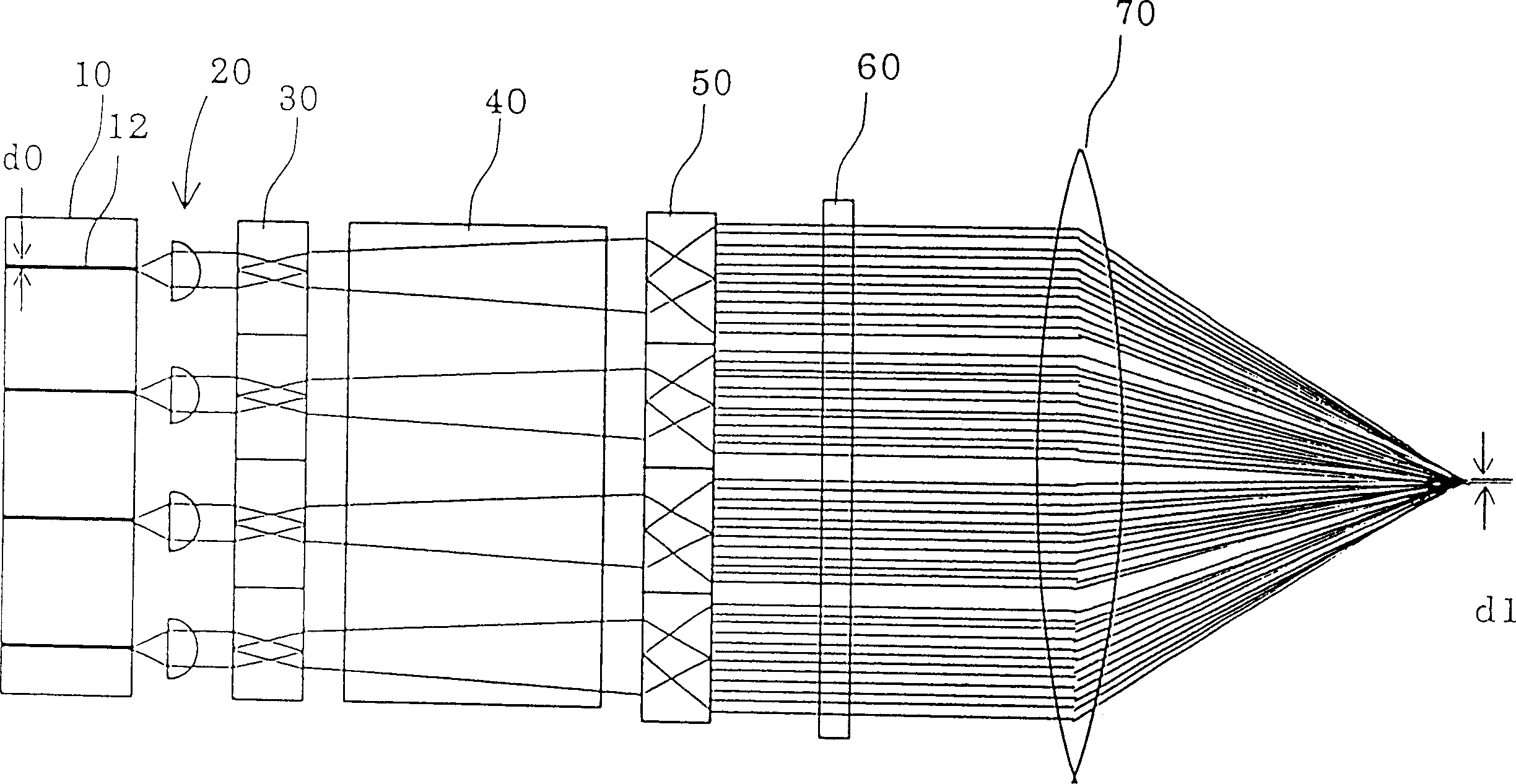

[0073] figure 2 is a plan view of the semiconductor laser device of the present invention, image 3 for its front view.

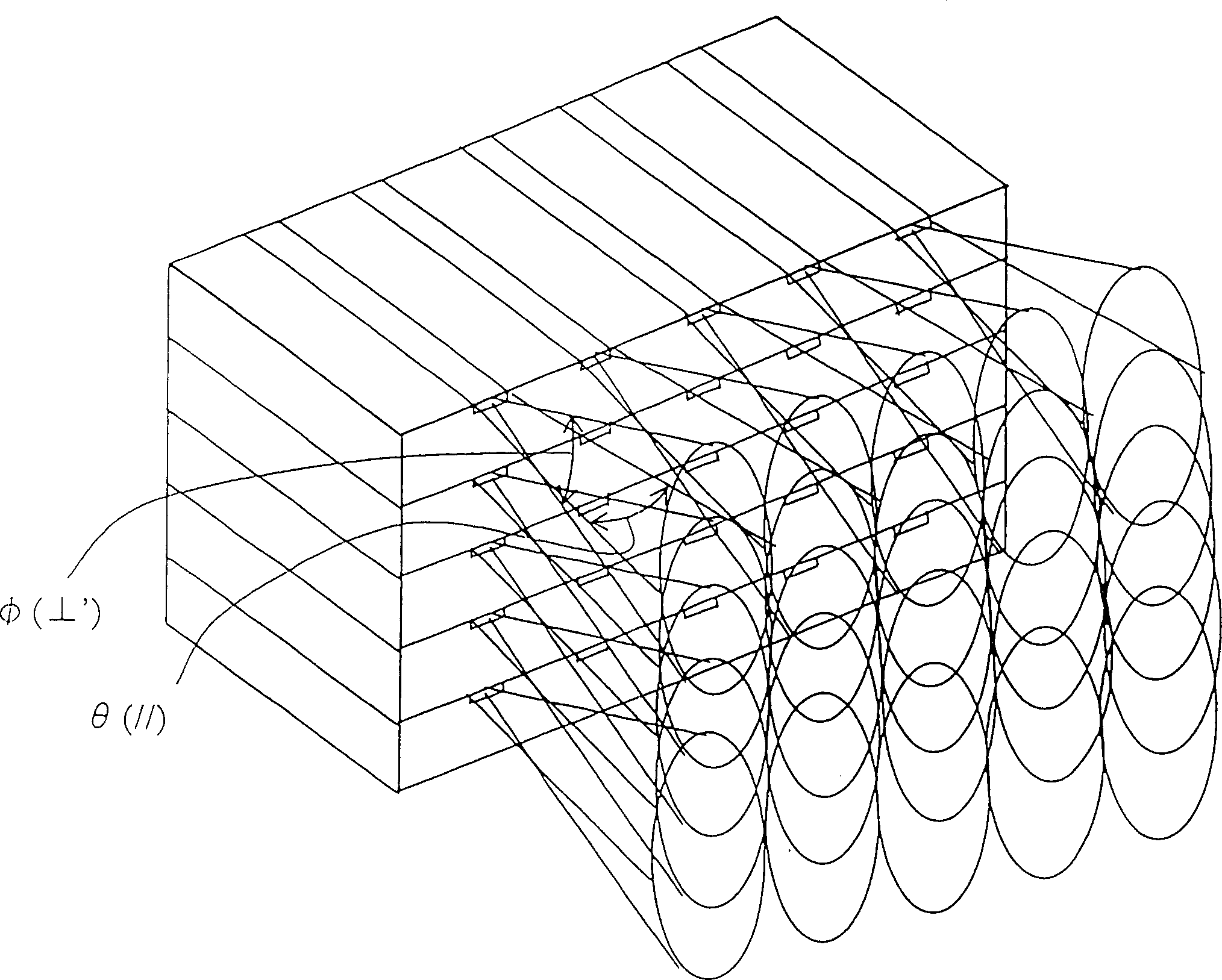

[0074] The stacked array semiconductor laser 10 is stacked with a linear array semiconductor laser (4 layers are shown in the figure) within a height range of 5 to 40 mm. In the linear array semiconductor laser, between intervals with a width of about 10 mm, 10 to 100 active layer strips 12 emitting laser beams (in the figure, 6 are shown for convenience) are arranged in a row.

[0075] In the cross-section of each active layer strip 12, for example, the width is in the range of 100-200 μm, and the thickness is in the range of 0.1-1 μm. The laser light emitted from the end face of the active layer strip constitutes the light emitting source of the stacked array semiconductor laser 10. , the radiation angle in the thickness direction is in the rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com