Position design of alignment marks

A technology for aligning marks and designing structures, which is applied in the direction of photomechanical equipment, pattern surface photolithography, optics, etc. It can solve the problems affecting the correct reflection path of light and affecting the stability, so as to achieve good flatness and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

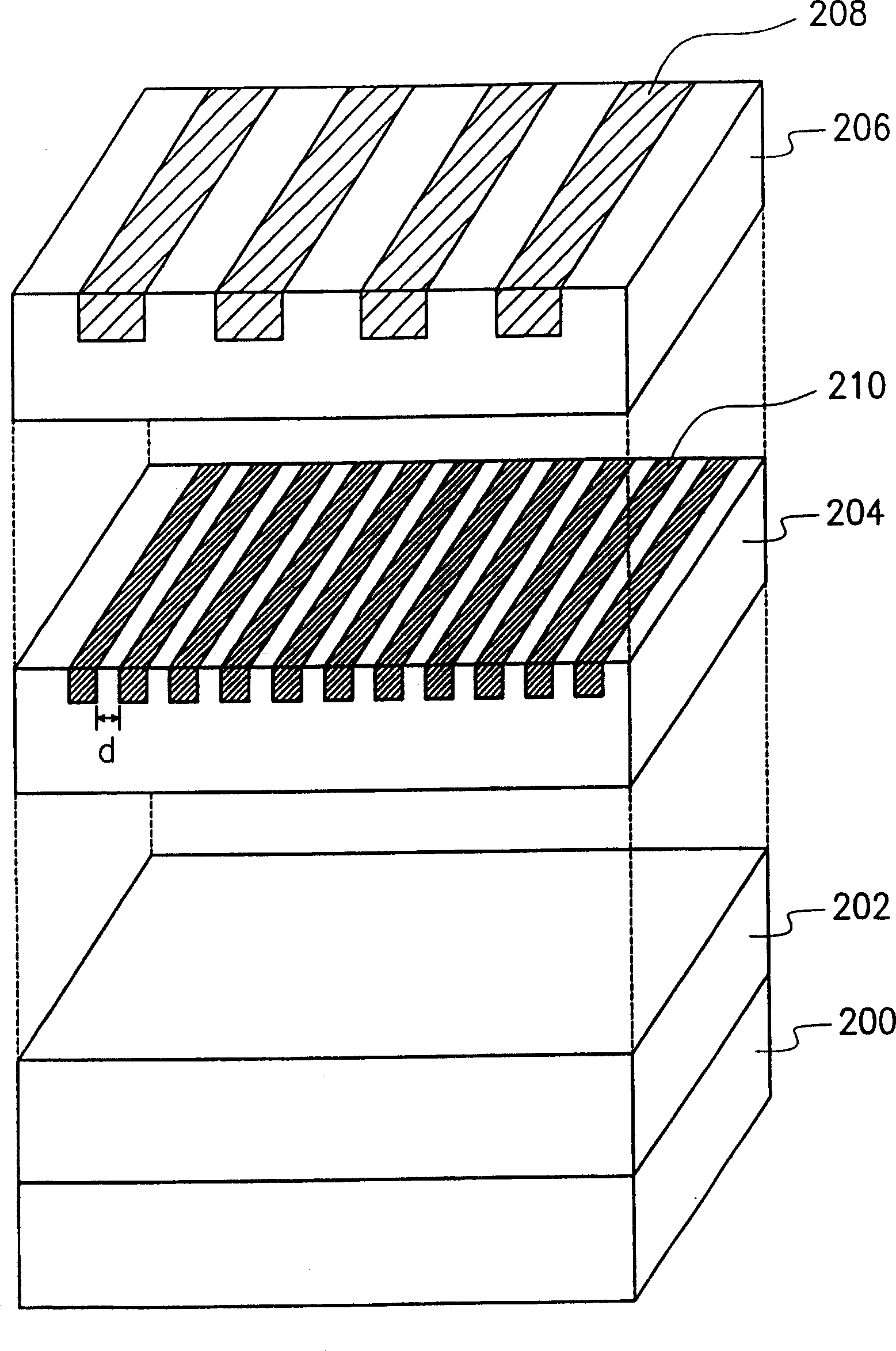

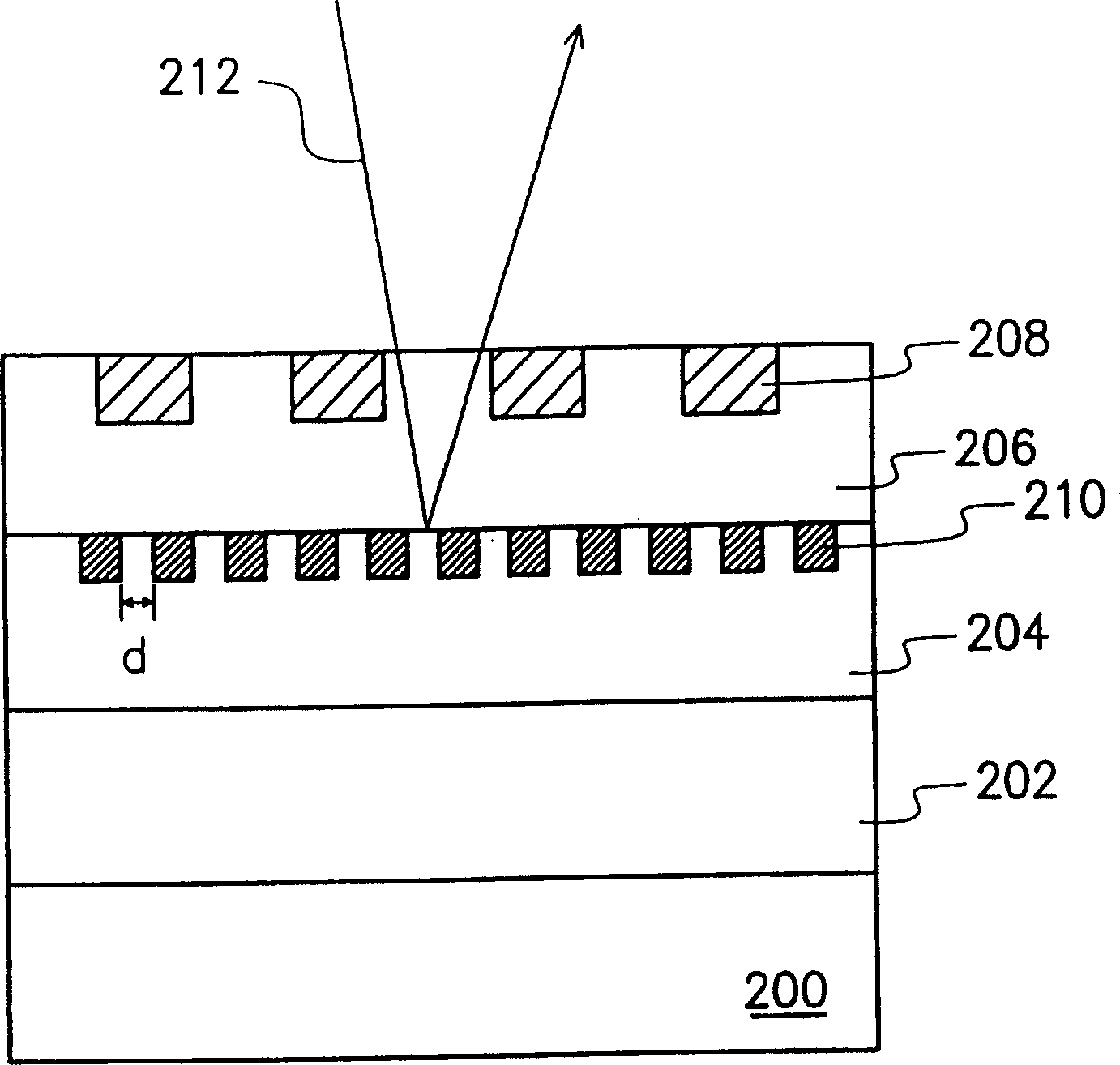

[0024] Please also refer to figure 2 as well as image 3 , figure 2 What is shown is an exploded schematic diagram of the three-dimensional structure of the position design of the non-zero layer alignment mark of the preferred embodiment of the present invention, and image 3 What is shown is a cross-sectional schematic diagram of the positional design of the non-zero layer alignment mark of the preferred embodiment of the present invention.

[0025] Depend on figure 2 and image 3 It can be seen that the alignment mark 208 is disposed in a planarized dielectric layer 206 on the semiconductor substrate 200, and the method for forming the alignment mark 208 is, for example, firstly forming several long lengths with similar positions in the dielectric layer 206. strip-shaped openings (not shown), and metal material is filled in the strip-shaped openings to form non-zero layer alignment marks composed of a plurality of metal lines. Usually, the alignment mark manufacturin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com