Magnetic filter system

A filter system and magnetic zone technology, applied in the direction of filter separation, magnetic separation, separation methods, etc., can solve the problem of not being able to further retain particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

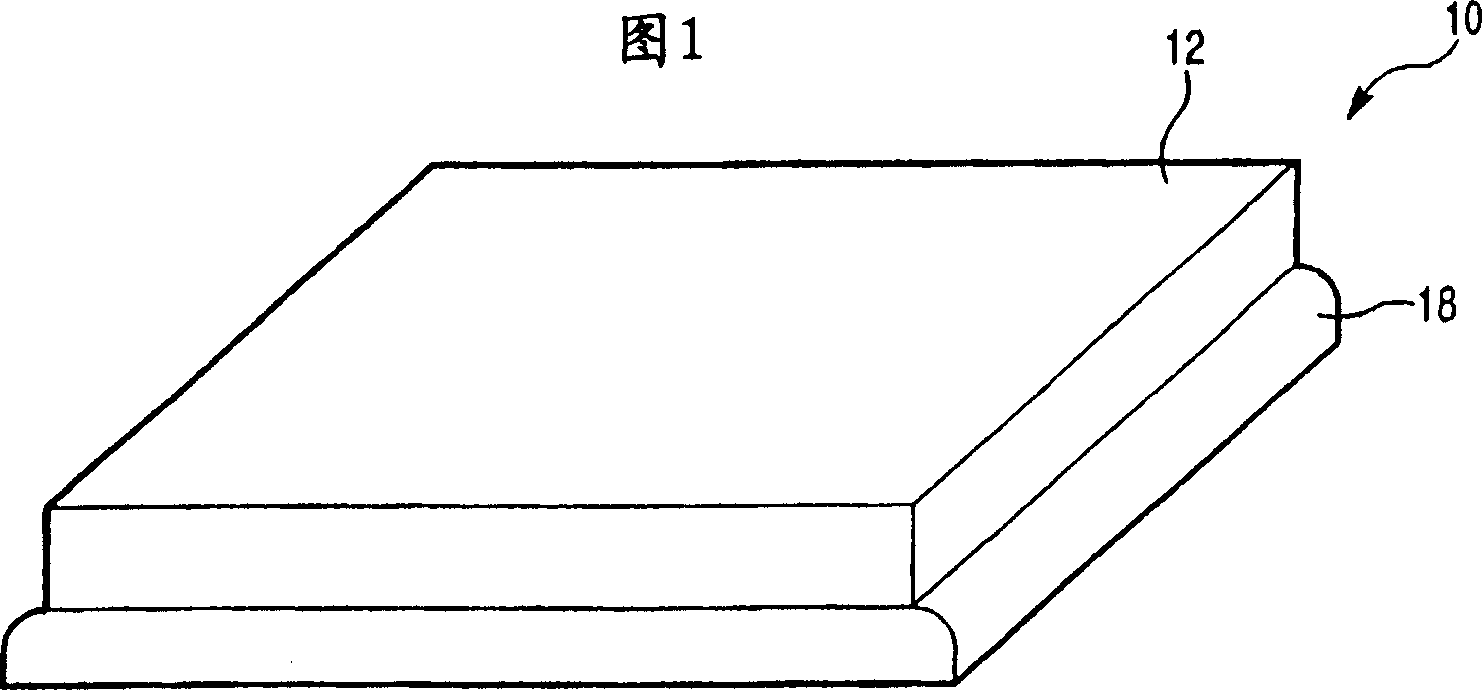

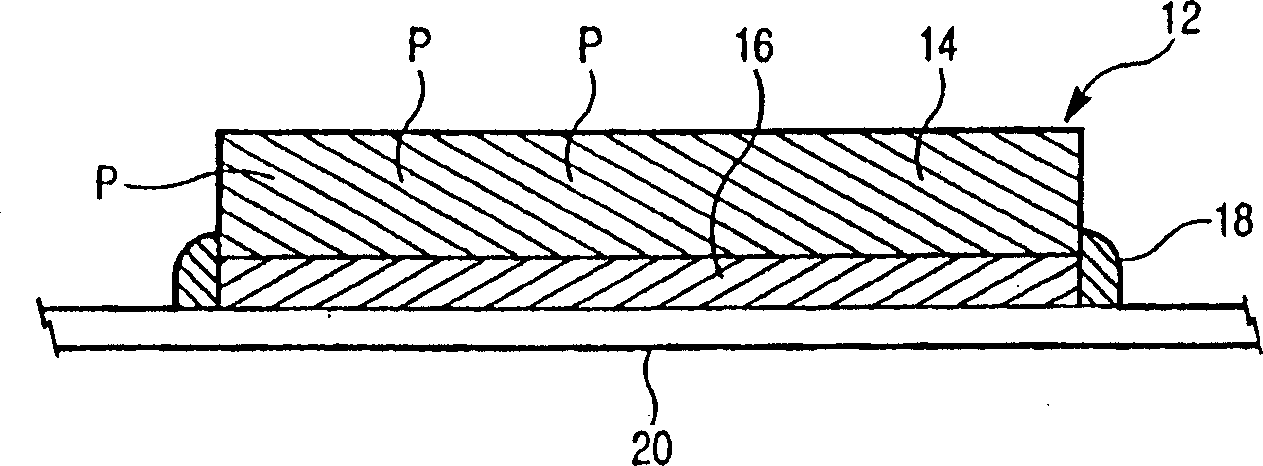

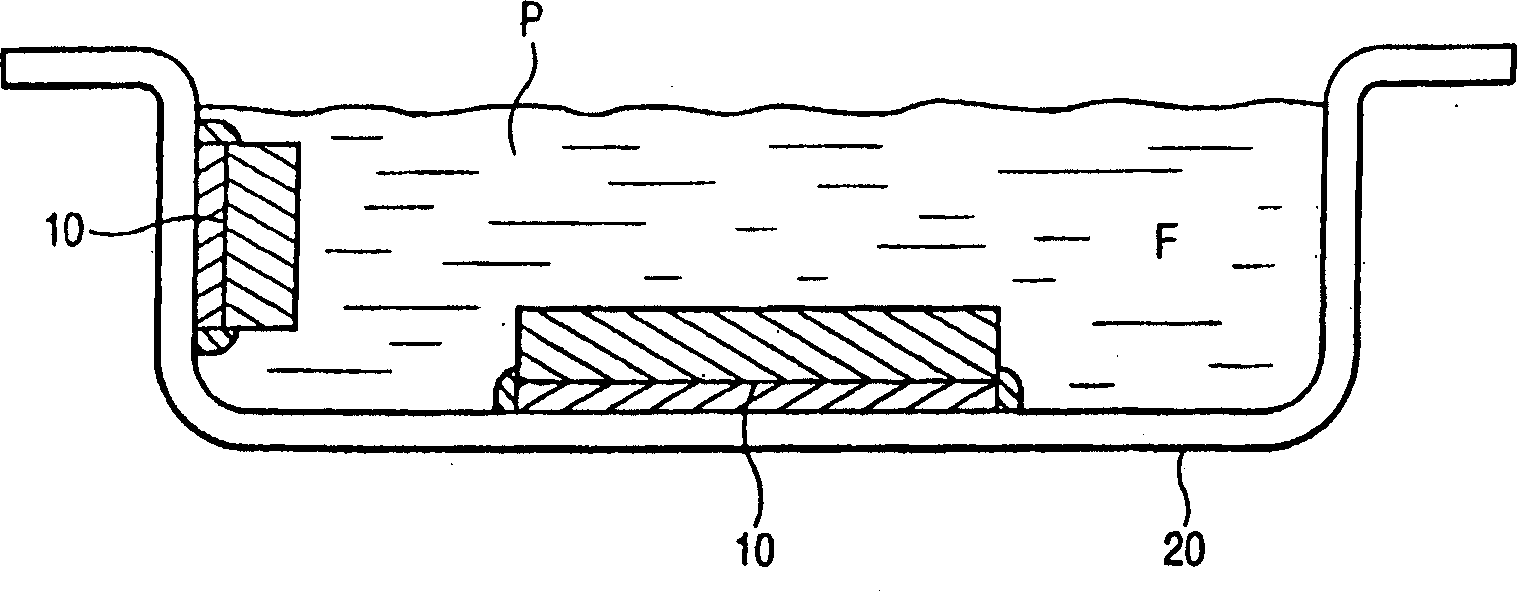

[0024] In general, some embodiments of the present invention provide filtration systems utilizing two-part filters. The two-part filter includes a fibrous region substantially adjacent to a magnetic region, which is typically disposed near an interior surface of the liquid handling system, and the fibrous region extends into the liquid to be filtered. The system may include a housing forming a lip around the perimeter of the two-part filter. In other embodiments, the magnetic material may be part or all of the fiber region itself, the discrete parts being optional.

[0025] Referring now to the drawings, and in particular FIGS. 1 and 2 , an embodiment of a filtration system includes a magnetic filtration system for filtering metal particles from a liquid in a liquid container of a mechanical system, and includes a first magnetic layer and a magnetic layer adjacent to and overlying the magnetic layer. the second fiber layer.

[0026] More specifically, filtration system 10 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com