Wear-resistant flame-retardant TPU material and preparation method thereof

A composite flame retardant and raw material technology, applied in the field of TPU materials, can solve problems such as surface wear and affect the service life of TPU, and achieve the effects of strong heat insulation, good rigidity, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

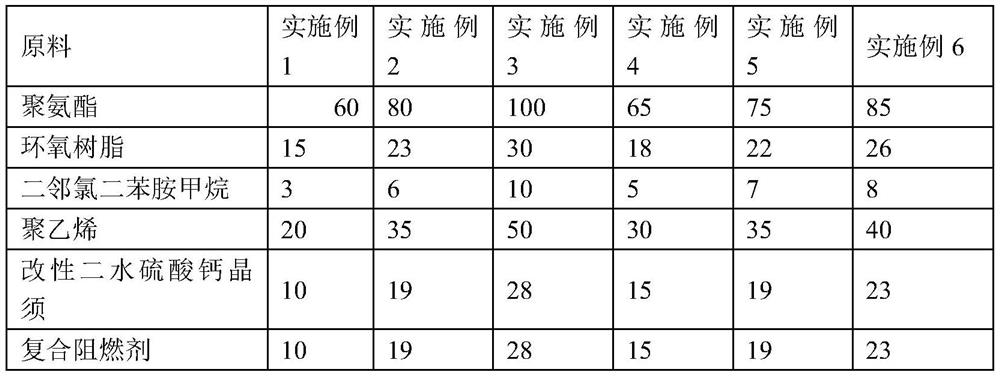

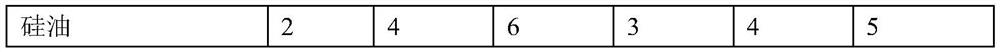

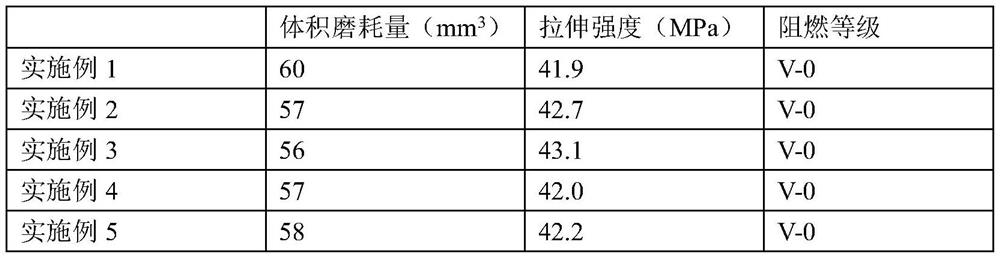

Examples

preparation example 1

[0042] A modified calcium sulfate dihydrate whisker prepared by the following method:

[0043] S1: Mix 10kg of calcium oxide and 90kg of water evenly to obtain a calcium hydroxide suspension, then place the calcium hydroxide suspension at a temperature of 70°C and stir at a speed of 150r / min for 25min;

[0044] S2: Heat the calcium hydroxide suspension to 90°C, stir at a speed of 380r / min, and at the same time add concentrated sulfuric acid dropwise to the calcium hydroxide suspension at a flow rate of 1mL / min for 30min, then Insulate for 35 minutes, cool down, then carry out suction filtration, put the filter residue at a temperature of 80°C and dry to constant weight to obtain calcium sulfate dihydrate whiskers;

[0045] S3: Put calcium sulfate dihydrate whiskers into ethanol solution to prepare a suspension of calcium sulfate dihydrate whiskers with a calcium sulfate dihydrate whisker concentration of 8%, raise the temperature to 75°C, Add tetrabutyl titanate to the suspen...

preparation example 2

[0048] A modified calcium sulfate dihydrate whisker prepared by the following method:

[0049] S1: Mix 11kg of calcium oxide and 95kg of water evenly to obtain a calcium hydroxide suspension, then place the calcium hydroxide suspension at a temperature of 75°C and stir at a speed of 200r / min for 30min;

[0050] S2: Heat the calcium hydroxide suspension to 95°C, stir at a speed of 400r / min, and at the same time add concentrated sulfuric acid dropwise to the calcium hydroxide suspension at a flow rate of 2mL / min for 35min, then Insulate for 40 minutes, cool down, and then perform suction filtration, put the filter residue at a temperature of 90°C and dry to constant weight to obtain calcium sulfate dihydrate whiskers;

[0051] S3: Put calcium sulfate dihydrate whiskers into ethanol solution to prepare a suspension of calcium sulfate dihydrate whiskers with a calcium sulfate dihydrate whisker concentration of 9%, raise the temperature to 80°C, Add tetrabutyl titanate to the susp...

preparation example 3

[0054] A modified calcium sulfate dihydrate whisker prepared by the following method:

[0055] S1: Mix 12kg of calcium oxide and 100kg of water evenly to obtain a calcium hydroxide suspension, then put the calcium hydroxide suspension at a temperature of 80°C and stir at a speed of 250r / min for 35min;

[0056] S2: Warm up the calcium hydroxide suspension to 100°C, stir at a speed of 420r / min, and at the same time add concentrated sulfuric acid dropwise to the calcium hydroxide suspension at a flow rate of 3mL / min for 40min, then Insulate for 45 minutes, cool down, and then carry out suction filtration, put the filter residue at a temperature of 100°C and dry to constant weight to obtain calcium sulfate dihydrate whiskers;

[0057] S3: Put calcium sulfate dihydrate whiskers into ethanol solution to prepare a suspension of calcium sulfate dihydrate whiskers with a calcium sulfate dihydrate whisker concentration of 10%, raise the temperature to 85°C, Add tetrabutyl titanate to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com