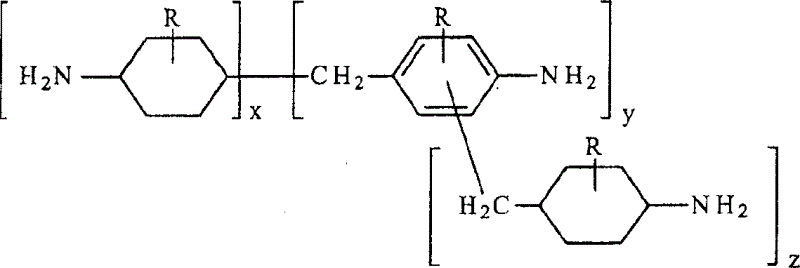

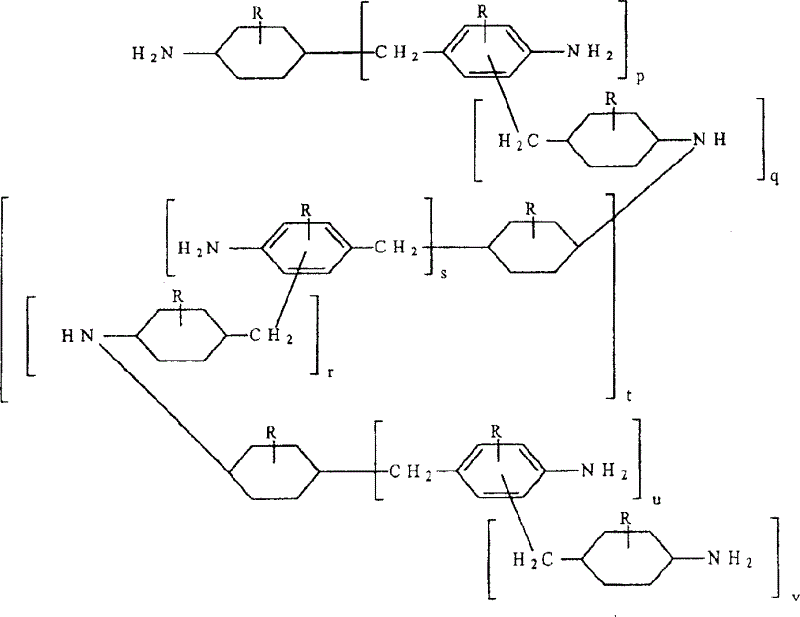

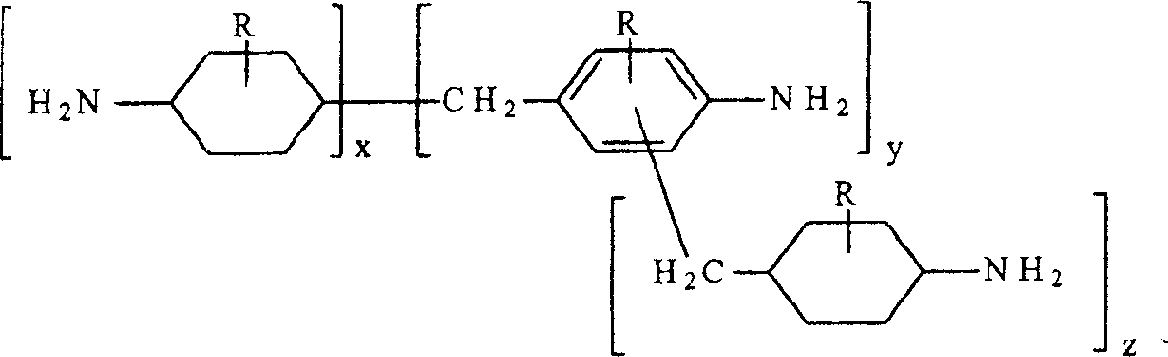

Hydrogenation of methane diphenylamine homolog and epoxy resin cured therefrom

A methylene bridged and resin technology, applied in the field of methylene bridged polyamine and its preparation, can solve the problems of long reaction time, unsuitable raw material for hydrogenated methylene diphenylamine, low yield and the like, and achieves The effect of excellent thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A series of epoxy curing agents are prepared from heavy MPCA raw materials by blending various raw materials. These samples were then compared with MPCA epoxy curing agent, where MPCA is based on US5,280,091.

[0064] Sample 1 was prepared by hydrogenating MDA-50, then removing the 2-ring component, leaving the heavy MPCA as the bottom fraction.

[0065] Sample 2 was prepared by hydrogenating a 1:1 mixture of MDA-85 (15% oligomer) and MDA-50, and then removing the 2-membered ring component, leaving the heavy MPCA as the bottom fraction.

[0066] Sample 3 was prepared from a 1:1 mixture of MDA-85 and MDA-50. After the hydrogenation (going deeper to obtain higher secondary amine components), the 2-membered ring component is removed, and the heavy MPCA remains as the bottom fraction.

[0067] Sample 4 is similar to sample 3, except that there is a higher level of partially hydrogenated methylene diphenylamine (ABCHA) but a lower content of secondary amines.

[0068] Control sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com