Lapping apparatus and lapping method

A device, a technology for lapping films, applied in grinding/polishing equipment, lapping devices, lapping machine tools, etc., to solve problems such as hindering smooth operation of valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

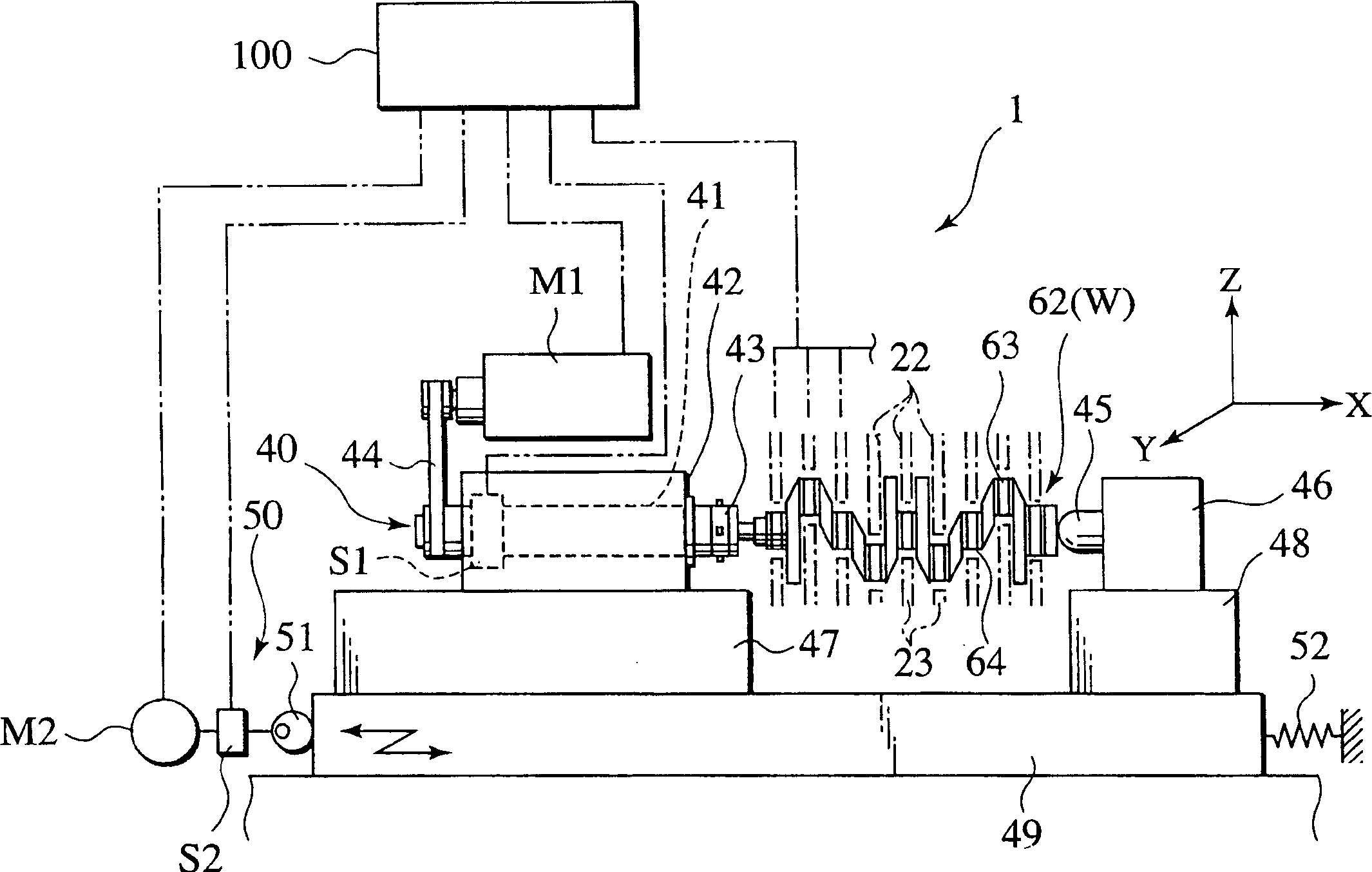

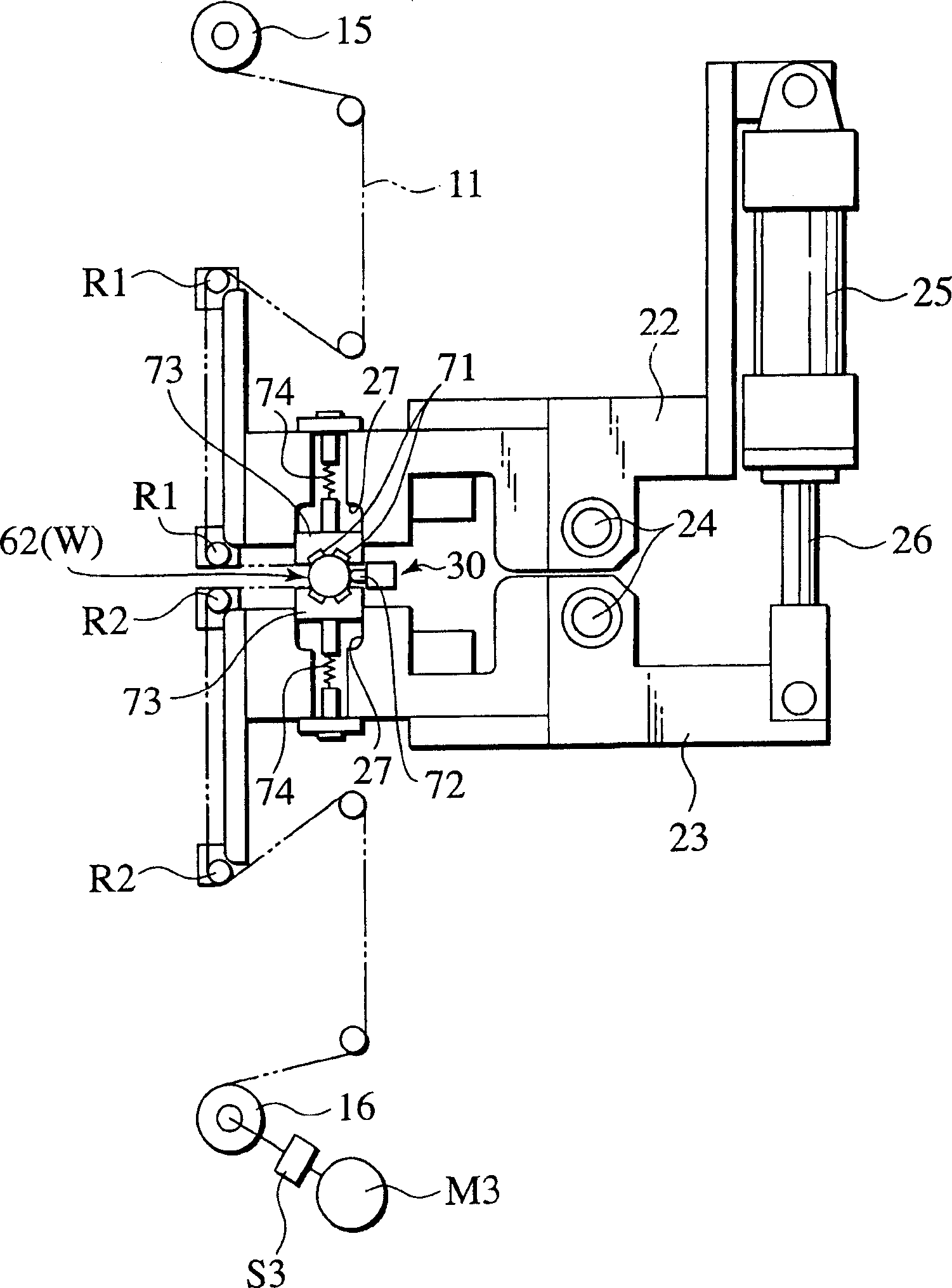

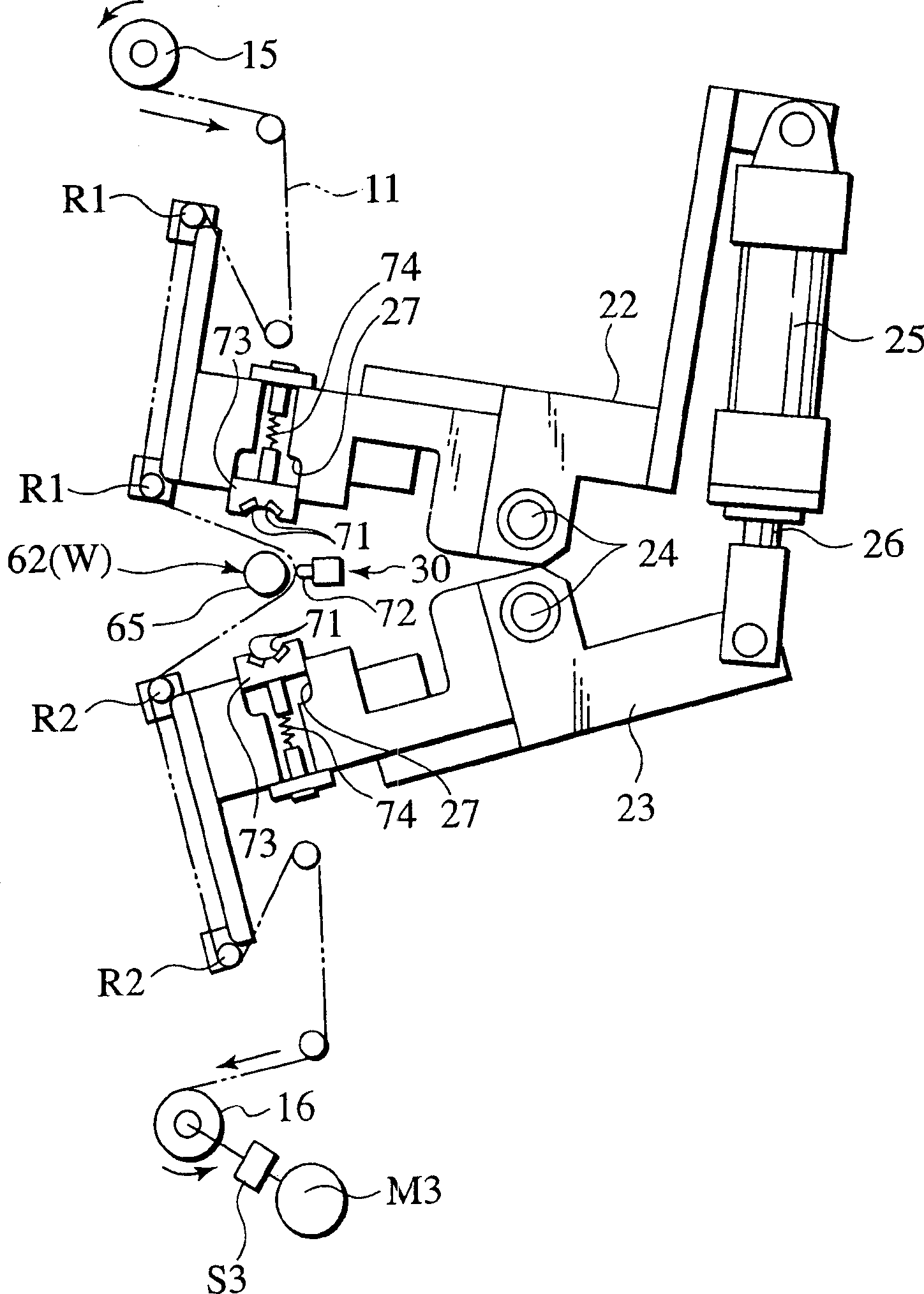

[0050] figure 1 A grinding apparatus 1 according to a first embodiment of the present invention is shown. figure 2 The closed state of the upper and lower arms 22, 23 provided in the grinding apparatus 1 in an openable and closable manner is shown. image 3 The open state of the upper and lower arms 22, 23 is shown. Figure 4A and 4B The essential parts of the grinding apparatus 1 are shown, wherein Figure 4A A state is shown in which the second bottom plate 72 constituting the soft bottom plate is driven to the operating position in which the second bottom plate 72 is pushed toward the mouth base 67 of the lubricant hole 66, and Figure 4B A state is shown in which the soft soleplate is driven to an inoperative position in which the soft soleplate is separated from the mouth base 67 of the lubricant hole 66 . 5A to 5C as well as 6A to 6C The range in which the soft soleplate 72 is driven between the non-operating position and the operating position is shown. Figure...

no. 2 example

[0092] Figure 10 The closed state of the upper and lower arms 22, 23 provided in the grinding apparatus 2 according to the second embodiment of the present invention in an openable and closable manner is shown. in addition, Figure 11A and Figure 11B The bottom plate 80 and the bottom plate shell 83 used in the second embodiment are shown. It should be noted that the same elements in the second embodiment as those in the first embodiment are denoted by the same reference numerals as in the first embodiment, and descriptions thereof will be omitted.

[0093] like Figure 10 As shown, the grinding apparatus 2 according to the second embodiment is suitable for grinding a crankshaft 62 as a workpiece W having the same opening portion 66 (such as a lubricant) formed with an opening as in the first embodiment. The pre-machined surface 65 of the hole), and the polishing apparatus 2 includes the polishing film 11 and the base plate 80 for pressing the abrasive-grained surface of...

no. 3 example

[0111] Hereinafter, a third embodiment of the present invention will be described with reference to the accompanying drawings. The same elements in the third embodiment as those in the first embodiment are denoted by the same reference numerals as in the first embodiment, and descriptions thereof will be omitted.

[0112] Figure 12 A grinding apparatus 3 according to a third embodiment of the present invention is shown. Figure 13 The closed state of the upper and lower arms 22, 23 provided in the grinding apparatus 3 in an openable and closable manner is shown. figure 1 4 shows the open state of the upper and lower arms 22, 23. Figure 15 The essential parts of the grinding device 3 are shown. also, Figure 16Camshaft position with vibration is shown. Figure 17 The structure corresponding to the chassis pressing unit 330 (as opposed to the chassis driving unit) is shown. Figure 18 Changes in the bottom plate pressing force P are shown. and, Figure 19A An exemplar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com