Production of oil seed protein isolate

A technology for protein separation and oilseed meal, applied in protein food ingredients, protein composition of vegetable seeds, plant protein processing, etc., can solve the problem of not providing data on product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

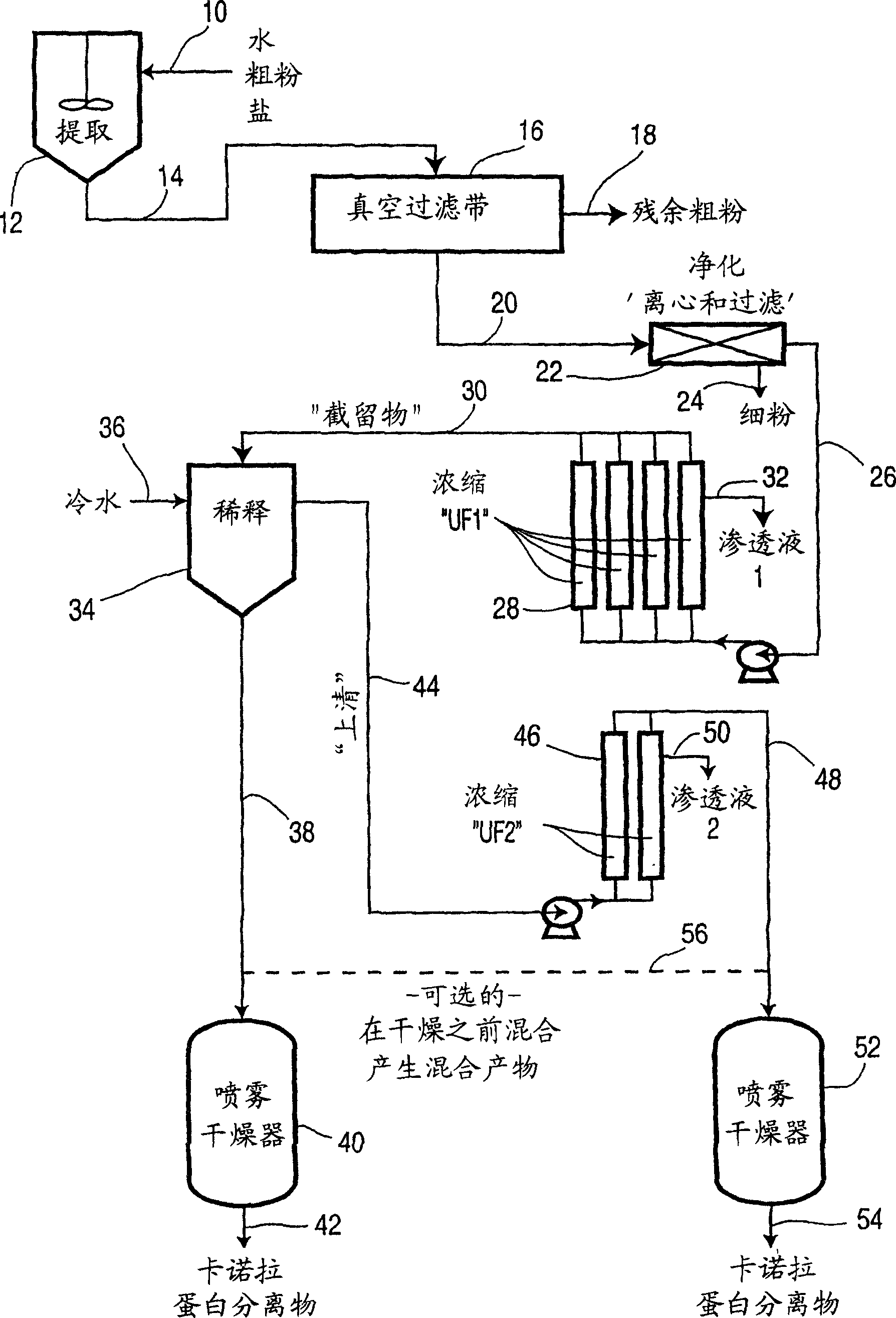

Method used

Image

Examples

Embodiment 1

[0064] This example illustrates the method of the invention.

[0065] At room temperature, "a" Kg commercial canola coarse powder was added to "b"L 0.15mol / L NaCl solution, and stirred for 30 minutes to form a protein aqueous solution with a protein content of "c" g / L. Canola meal residue was removed and washed on a vacuum filter belt. The resulting protein solution was clarified by centrifugation, yielding "d" L of clarified protein solution having a protein content of "e" g / L.

[0066] The volume of the protein extract or "f" L of the protein extract is reduced to "g" L by an ultrafiltration system using a membrane with a molecular weight cut-off of "h" Daltons. The resulting concentrated protein solution contains "i" g / L of protein.

[0067] The concentrated solution at temperature "j"°C is diluted "k" times with water at 4°C. A white cloud of protein micelles immediately forms and settles. The upper layer was removed for dilution with water, and a precipitated, viscous...

Embodiment 2

[0074] The process of Example 1 was repeated by changing the conditions in the above method. Several parameters were investigated.

[0075] (a) Extract parameters

[0076] The extraction parameters were varied to determine their effect on the obtained concentrated protein solution. The results are shown in Table II.

[0077] Table II

[0078] Extraction concentration

extraction temperature

extraction time

NaCl solution

concentration

extract

pH

5%w / v

13℃

30min

0.15M

6.4

5.3g / L

15%w / v

13℃

30min

0.15M

6.2

12.7g / L

15%w / v

8℃

30min

0.15M

-

6.6g / L

15%w / v

34℃

30min

0.15M

-

14.6g / L

15%w / v

22℃

10min

0.15M

5.9

10.5g / L

15%w / v

13℃

60min

0.15M

5.9

10.6g / L

[0079] ...

Embodiment 3

[0085] This example illustrates the effect of the temperature of the dilution water on the yield of protein isolate produced.

[0086] At room temperature, 1200Kg of commercial canola coarse powder was added into 8000L of 0.15mol / L NaCl solution, and stirred for 30 minutes to form a protein aqueous solution with a protein content of 17.4g / L. Canola meal residue was removed and washed on a vacuum filter belt. The resulting protein solution was clarified by centrifugation yielding 7464 L of clear protein solution with a protein content of 14.8 g / L.

[0087] Using a membrane with a molecular weight cut-off of 3000 Daltons, the volume of the concentrated protein extract is reduced through an ultrafiltration system. The resulting concentrated protein solution had a protein content of 230 g / L.

[0088] 50 ml aliquots of the concentrated solution were warmed to 30°C and then diluted 1:10 into tap water at 15°C. A small amount of white cloud-like material composed of very small mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com