Alloying hot galvanizing plating coat analysis method

An analysis method, hot-dip galvanizing technology, applied in the direction of testing metals, material inspection products, etc., can solve problems such as difficulty in separation, large analysis errors, and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Take sample 1 and analyze according to the following analysis method

[0067] (1) Preparation of coating metallographic samples

[0068] a. Sample mounting: first cut sample 1 into large pieces of 10×20mm, and cold mount with epoxy resin;

[0069] b. Sample cutting: After the above-mentioned metallographic sample after cold mounting is solidified, it is cut off from the middle at a slow speed with a grinding wheel;

[0070] c. Grinding and polishing: grind and polish the metallographic sample cut above, and rinse with alcohol during polishing. The sandpaper is from coarse to fine. Rinse and dry with alcohol every time you change the sandpaper to avoid contamination of the coating. rinse with alcohol;

[0071] d. Etching: After the metallographic sample rinsed with alcohol is dried, it is etched with an etchant, and the etchant is 0.5% nitric acid alcohol solution;

[0072] Through the above steps, the clear and complete coating metallographic structure of sample 1 w...

Embodiment 2

[0081] Sample 2 was analyzed by the same analysis method as in Example 1.

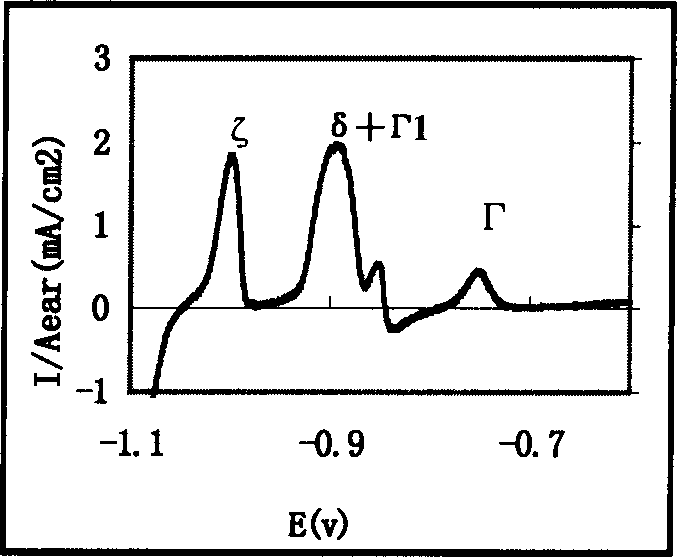

[0082] The quantitative results of sample 2 are shown in Table 3 as normal alloying. The Fe% of the coating is 9.1%. The coating structure has a certain amount of ζ phase and δ, Γ1, and Γ phase on the surface. The electron microscope scanning morphology of the coating is shown in the figure 6(b)(c). Its polarization curve is shown in Fig. 6(a).

Embodiment 3

[0084] Sample 3 was analyzed by the same analysis method as in Example 1.

[0085] The quantitative results of sample 3 are shown in Table 3. It is overalloyed, and the Fe% of the coating is 12.7%. There is no ζ phase in the coating structure, and it mainly consists of δ, Γ1, and Γ phases. The electron microscope scanning morphology of the coating is As shown in Figure 7(b)(c). Its polarization curve is shown in Fig. 7(a)

[0086] Table 3 quantitative calculation results (%)

[0087] Alloy Phase Name Sample 1 Sample 2 Sample 3

[0088] η 22

[0089] ζ 66(ζ+δ) 34

[0090] δ+Γ1 4(Γ1) 56 91

[0091] Γ 8 9 9

[0092] By adopting the analysis method of the invention, a complete, real and clear alloyed hot-dip galvanized coating structure can be obtained. Due to the low enough potential scanning speed, each phase of the coating can be dissolved phase by phase, and the dissolution process of each phase can be distinguished.

[0093] According to the polarization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com