Crystallizing kettle for preparing superfine powder using supercritical anti-solvent process

A technology of ultrafine powder and supercritical fluid, which is applied in the direction of liquid separation into beads and granulation, chemical/physical/physicochemical nozzle reactors, etc. It can solve the problem of large particle size and uneven particle size distribution of ultrafine particles. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

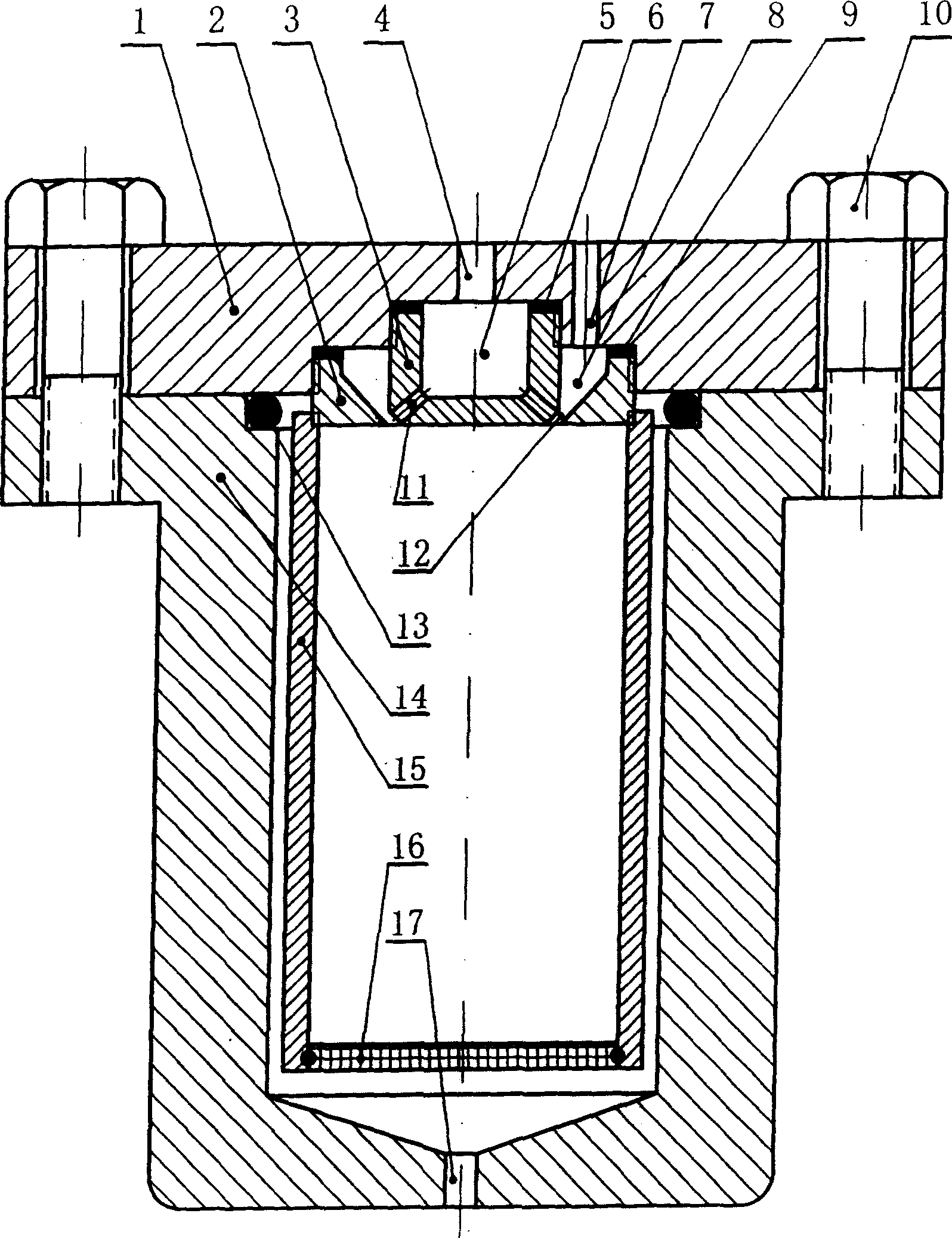

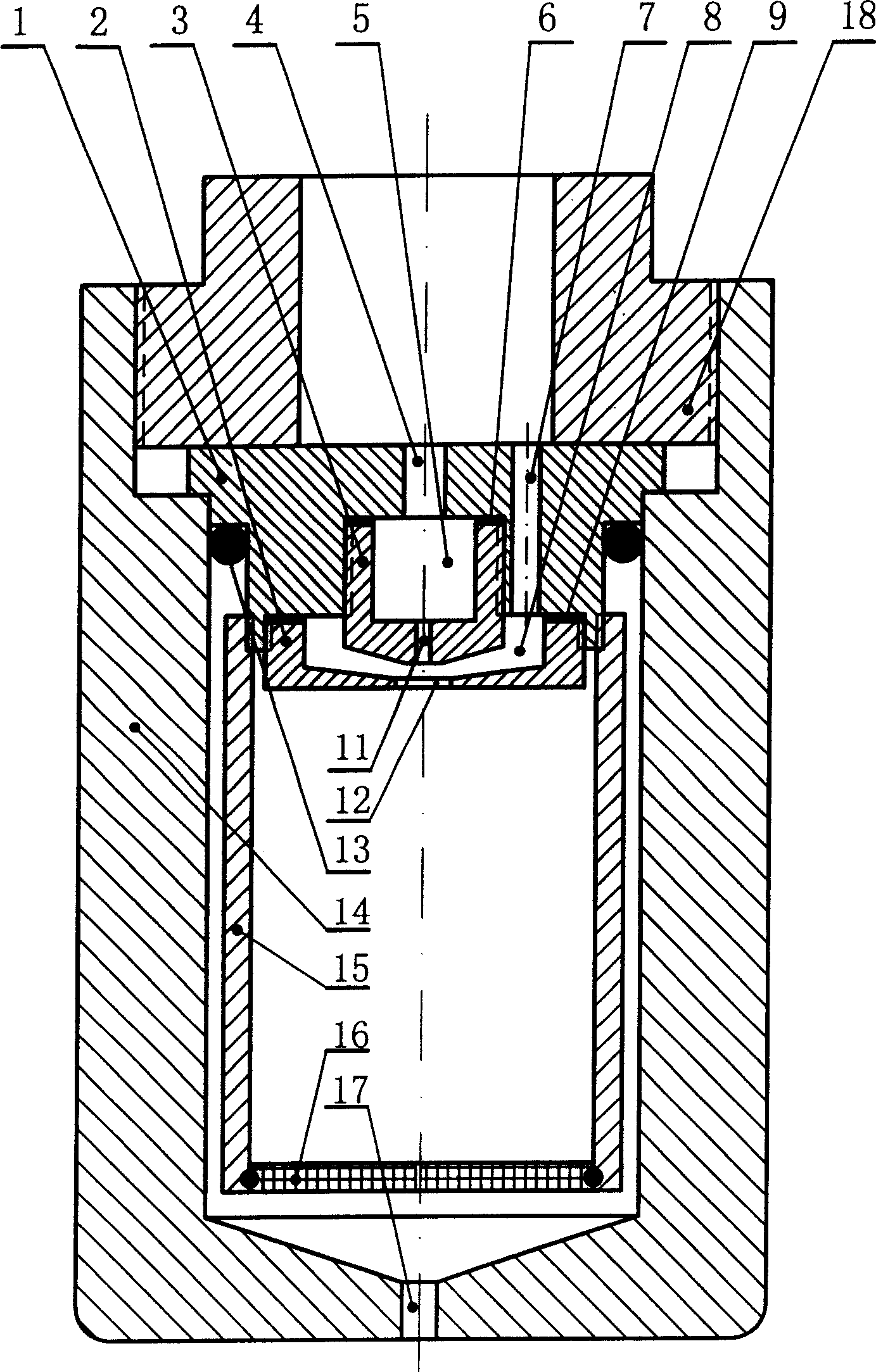

[0017] The first embodiment: the inner nozzle with multiple straight spray holes is suitable for occasions requiring larger output.

[0018] figure 1 The cylindrical inner nozzle 3 is provided with a cylindrical solution chamber 5, and a plurality of penetrating direct injection holes 11 are arranged at the lower end of the chamber wall. These direct injection holes are evenly and axially symmetrically distributed on a conical surface in a radial shape. . The upper end of the cavity wall is connected with the kettle cover 1, and the connection method can be threaded connection, welding and the like. The solution introduction hole 4 is set on the lid of the kettle. The solution cavity 5 of the inner nozzle 3 communicates with the solution introduction hole 4 . The junction of the chamber wall of the inner nozzle 3 and the kettle cover 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com