Vehicular wood active carbon and preparing method tehreof

A technology for activated carbon and vehicles, which is applied in the field of wooden activated carbon for vehicles and its preparation, which can solve the problems of complex procedures, low adsorption capacity, high cost, etc., and achieve the effects of shortened process flow, stable quality and reduced raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

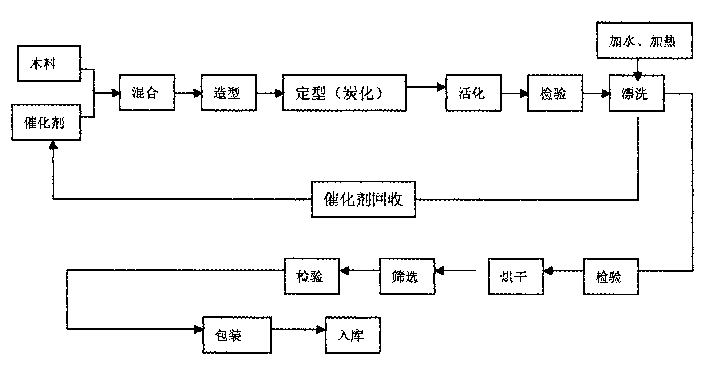

Method used

Image

Examples

Embodiment 1

[0027] The aqueous solution of zinc chloride prepared into Baume degree 60 and sawdust (less than 10% water) is mixed in a weight ratio of 3:1, and then mixed, shaped, shaped, carbonized, activated, rinsed, and dried. product. Its technological conditions are as shown in table 1, and the performance of the activated carbon product of preparation is as shown in table 2:

[0028] project

[0029] project

Embodiment 2

[0031] Mix 80% phosphoric acid and sawdust (less than 10% water) in a weight ratio of 2:1, and then process mixing, molding, setting, carbonization, activation, rinsing, and drying to make a product. Its process condition is as shown in table 3, and the activated carbon product performance of preparation is as shown in table 4:

[0032] project

[0033] project

[0034] The invention is a new type of activated carbon with high adsorption performance applied to a vehicle fuel volatilization recovery device (commonly known as a carbon tank), which can effectively reduce the emission of vehicle pollution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com