Magnetic damping board and preparing method thereof

A magnetic damping and damping plate technology, applied in mechanical equipment, vibration suppression adjustment, building components, etc., can solve problems such as difficulty in controlling thickness, and achieve the effect of simple and easy construction method, firm combination, and reduction of vibration and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Petroleum pitch (No. 10) 25%

[0033] Recycled rubber powder 3%

[0034] Atactic polypropylene 3%

[0035] Solvent oil (motor oil) 2%

[0037] Filler (talcum powder, asbestos powder, wollastonite powder, mica powder) balance

Embodiment 2

[0039] Petroleum pitch (No. 10) 35%

[0040] Recycled Rubber Powder 8%

[0041] Atactic polypropylene 8%

[0042] Solvent oil (motor oil) 4%

[0044] Filler (talcum powder, asbestos powder, wollastonite powder, mica powder) balance

Embodiment 3

[0046] Petroleum pitch (No. 10) 28%

[0047] Recycled rubber powder 5%

[0048] Atactic polypropylene 6%

[0049] Solvent oil (motor oil) 3%

[0050] Magnet Powder 30%

[0051] Filler (talcum powder, asbestos powder, wollastonite powder, mica powder) balance

[0052] B. Heating and mixing: heat to 180-200°C, melt the petroleum asphalt, and then add rubber powder and random polypropylene under stirring, so that the three raw materials are fully stirred and evenly mixed. When the temperature of the above-mentioned raw materials drops to 100-120 degrees , put in solvent oil, magnet powder, and filler, and stir until the above-mentioned raw materials are mixed evenly, which is damping micelles.

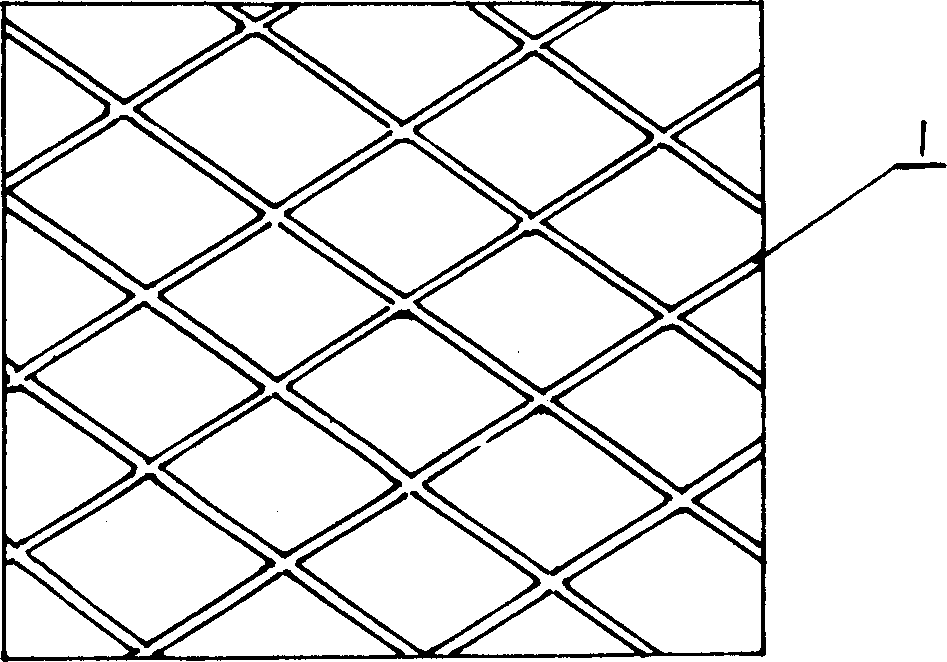

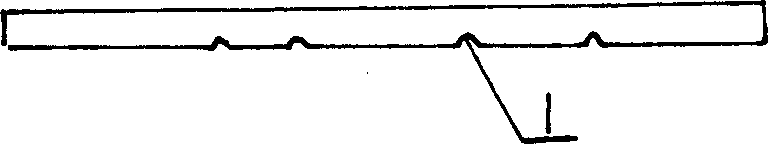

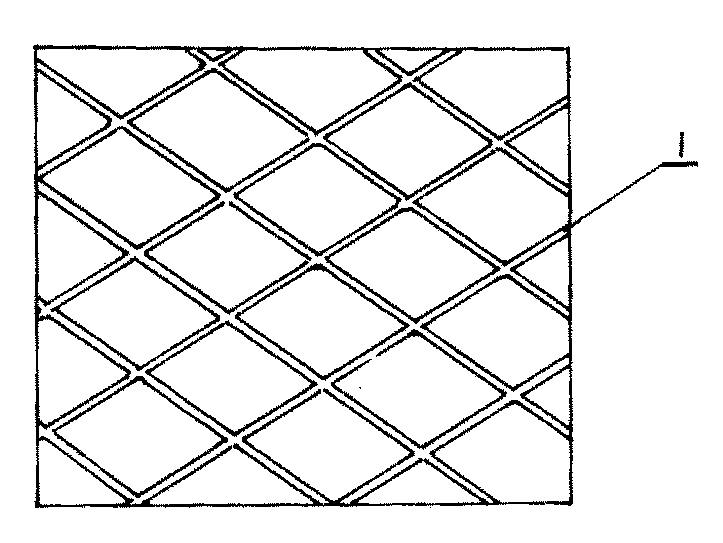

[0053] C. Tablet pressing: Put the prepared damping micelles into a special tablet press and press them into tablets according to the set thickness. One side of the pressed magnetic damping plate is smooth, and the other side has ribbed shallow grooves.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com