Intergrated optimization control method for mixed-batch assembling line

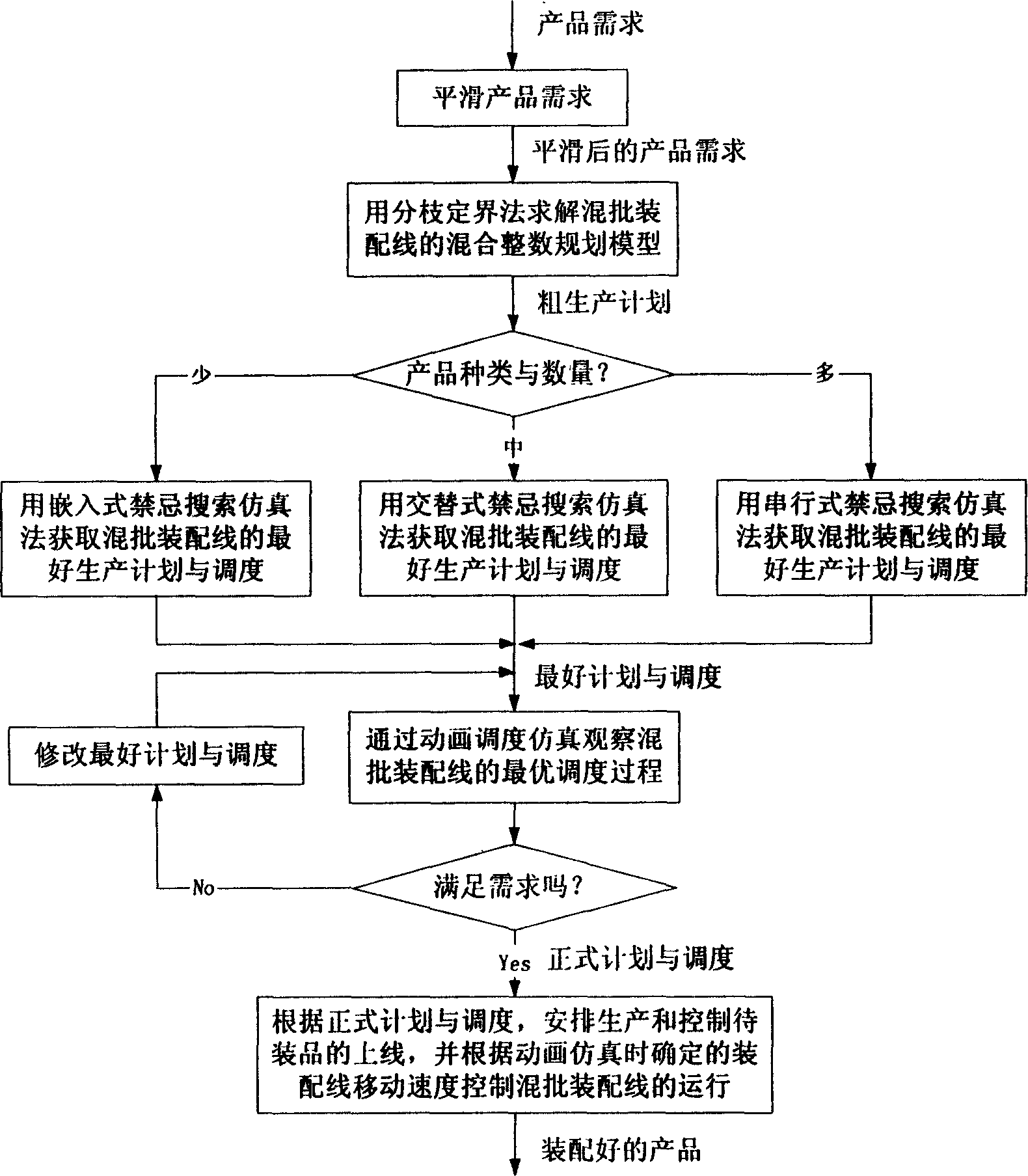

A technology for optimizing control and assembly line, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as computational complexity, and achieve the effect of solving integrated optimization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solution adopted by the present invention to solve its technical problems and the specific implementation methods are as follows

[0058] 1. Mixed batch assembly line:

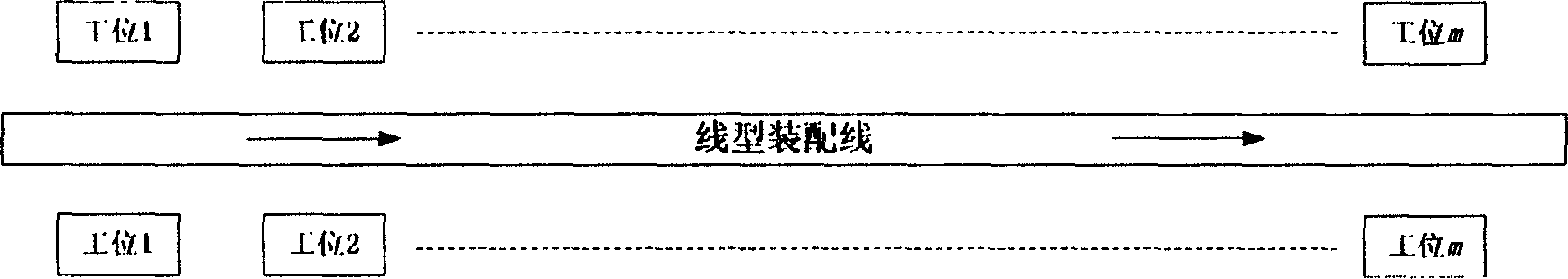

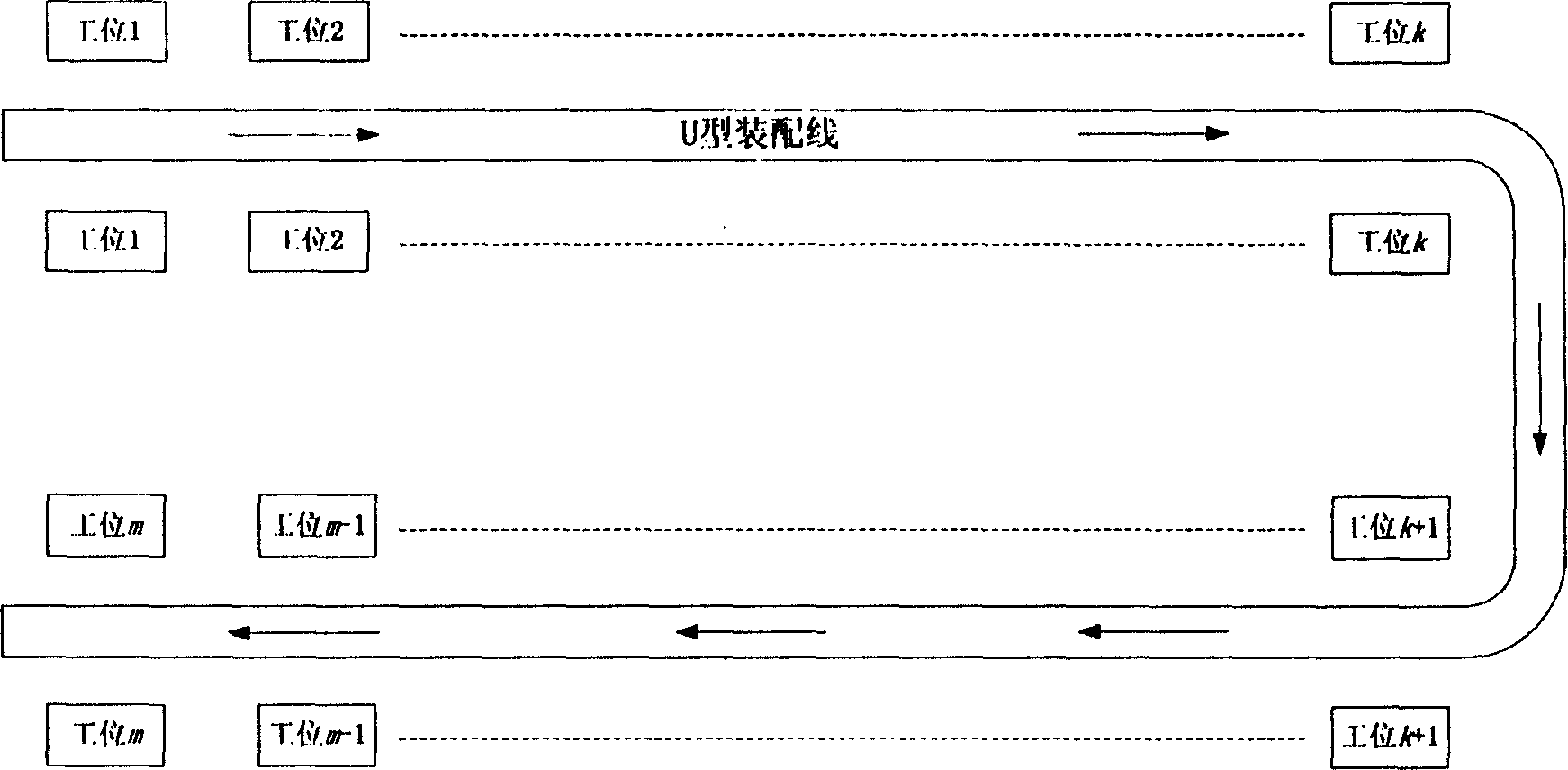

[0059] The mixed batch assembly line that the present invention relates to has two kinds, i.e. linear assembly line (see figure 1 ) and U-shaped assembly line (see figure 2 ). In the figure, stations 1 and m (1<k<m) represent the on-line assembly station and the off-line assembly station of the product respectively, and the arrows represent the moving direction of the product during the assembly process. Each assembly station can be distributed on both sides of the assembly line, or on one side, with a buffer zone. Each station can only hold at most one product at any time. The total number of products on the line is at most equal to the number m of stations on the line at any time, that is, if there is one product at each station at a certain moment, the only way to wait is for a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com