Method for powder disinfection and apparatus thereof

A technology of object powder and gas source device, which is applied in the field of object powder disinfection and disinfection device, which can solve the problems of destruction of active ingredients of traditional Chinese medicine powder, high irradiation cost, taste discount of condiments, dehydrated vegetables and tea leaves, etc., to reduce the cost of disinfection , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

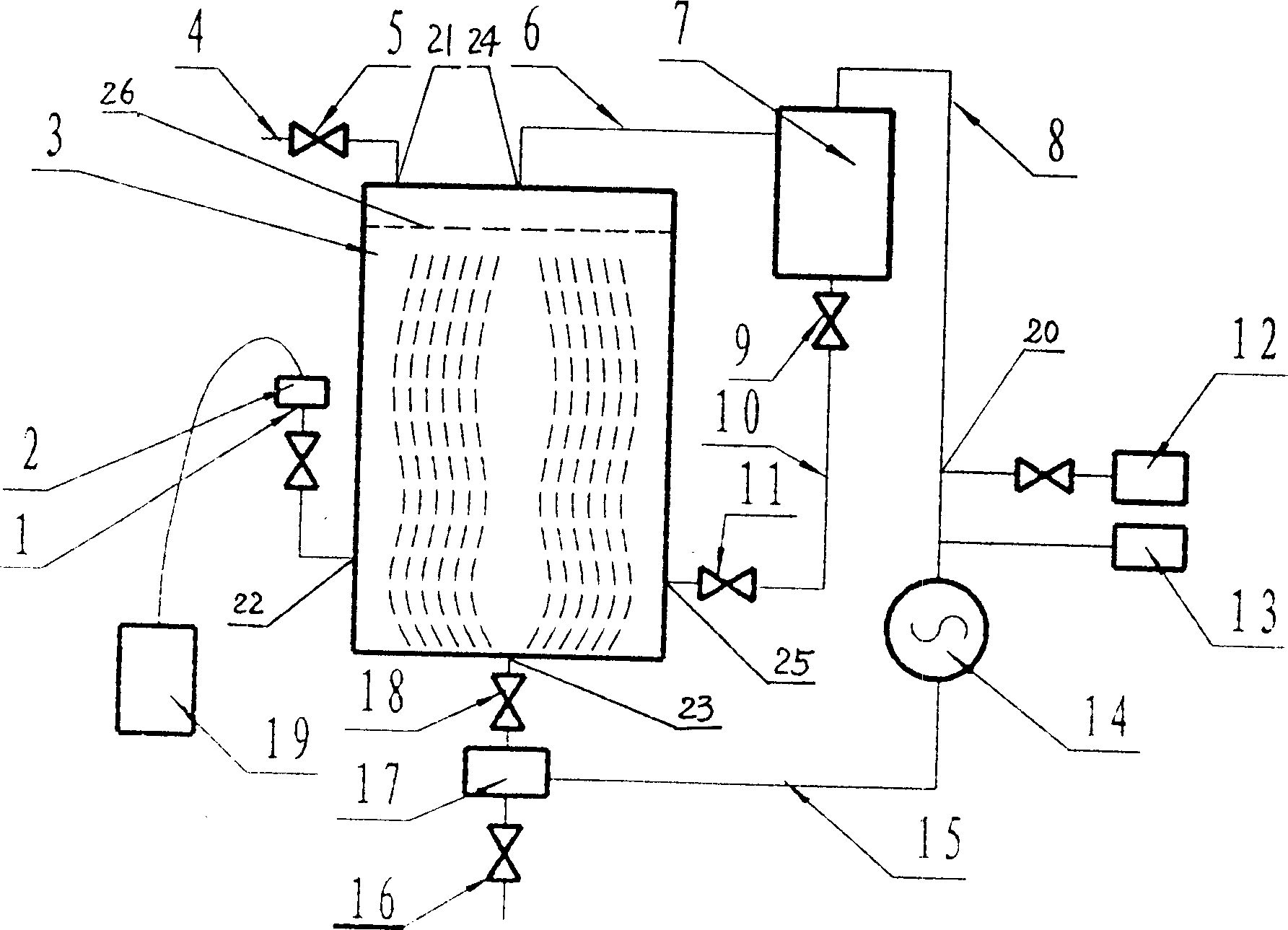

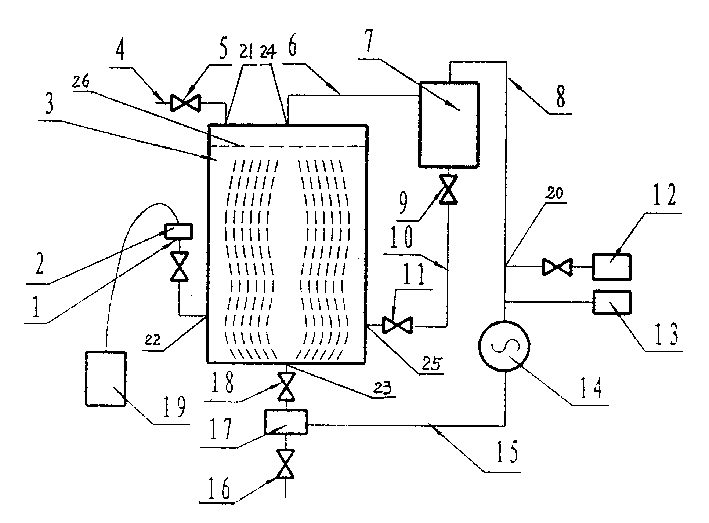

[0014] The method for sterilizing the powder of the present invention is to add the powder into the mixing bin, and pass the ozone-containing pressure disinfection gas source through the air inlet of the mixing bin, so that the powder is blown up and in a suspended state, so that The powder particles are fully contacted and mixed with ozone, and the pressure disinfection gas source passes through the powder filter device and returns to the air inlet of the mixing bin for recycling through the pressure disinfection gas source device, and the processed material is discharged from the discharge port. During disinfection, the mixing bin can be at normal temperature and pressure, or can be selected within the range of pressure 0-3Mpa and temperature 20-150°C. The source of ozone gas is preferably introduced from the bottom of the mixing bin. When the powder in the mixing bin is blown out, it can be recovered by a cyclone separator and added back into the mixing bin.

[0015] The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com