Cleaning processing method and apparatus for medical or medicinal rubber stopper

A processing device and processing method technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as inconsistent cleaning effects, uneven content and concentration of impurities, and unsatisfactory cleaning effects. Achieve the effect of reducing mutual contact friction, avoiding re-pollution, and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

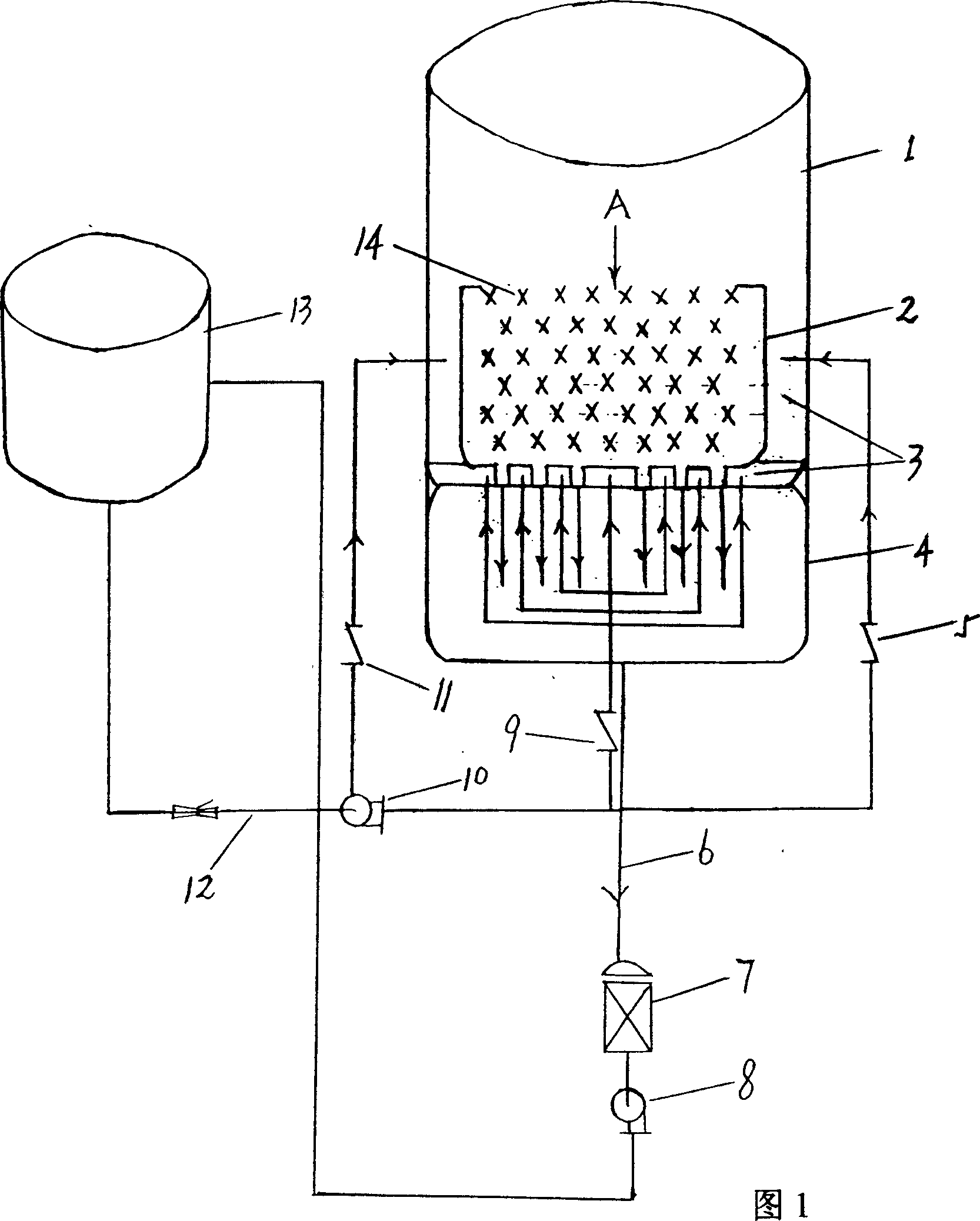

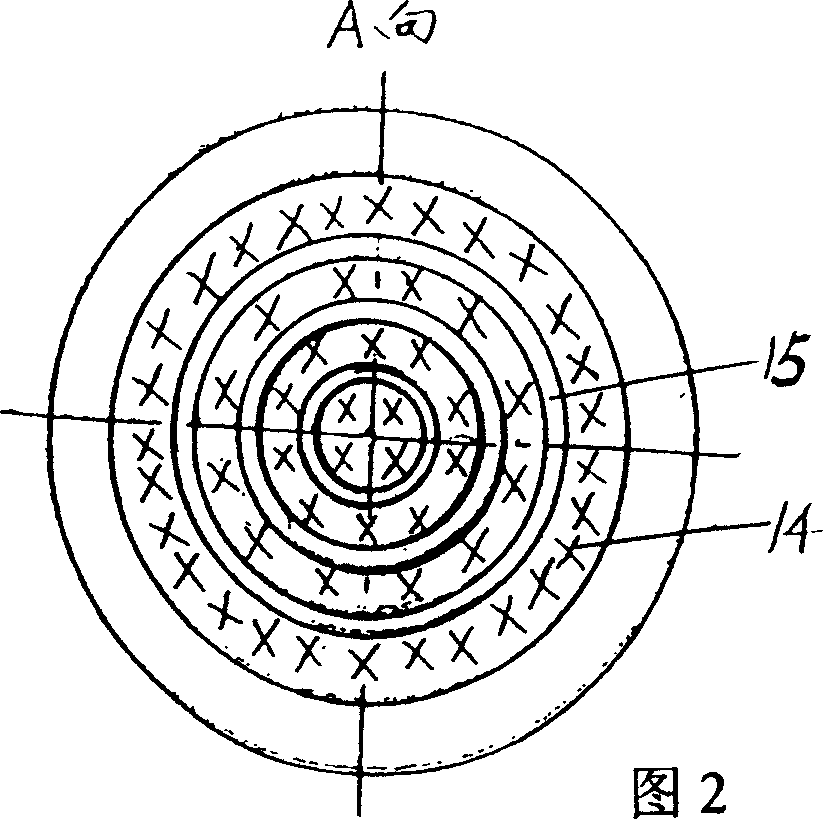

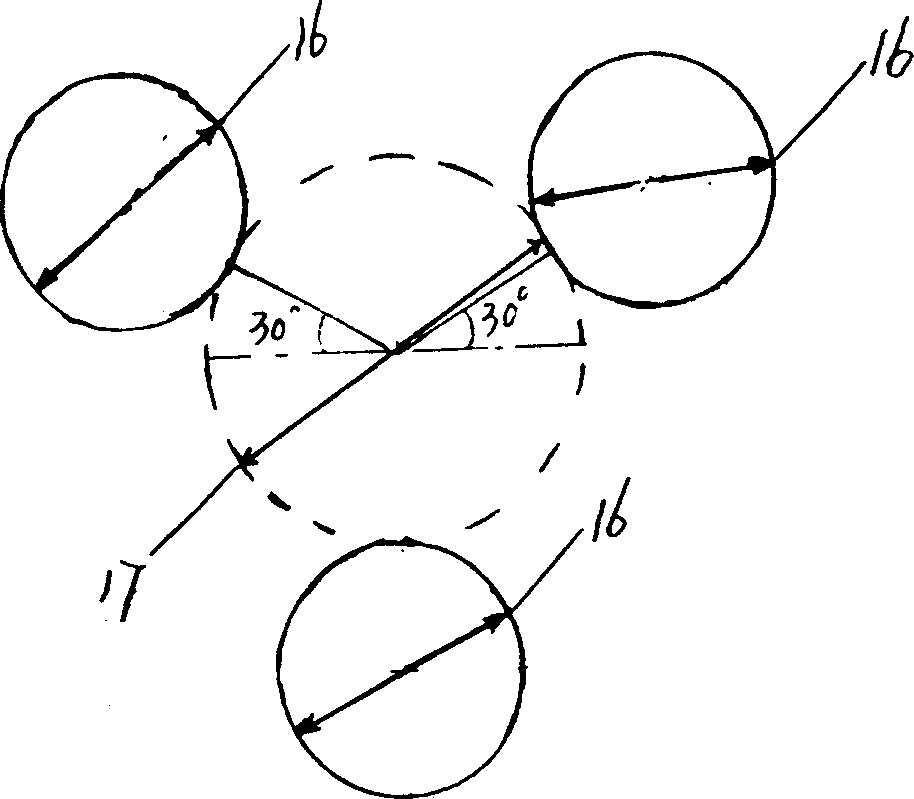

[0036] See Figure 1, Figure 2 and image 3 .

[0037] The device shown in FIG. 1 is adopted, and its composition includes a container 1 , a washing tub 2 , a water storage bucket 13 , a water inlet pipe 12 , and a water outlet pipe 6 . Container 1 is a cylinder with a diameter of D=800mm, and its bottom and side walls are arranged with water spray holes 14, and the aperture of the water spray holes is D 1 = 15mm, D 2 =40mm; the hole spacing D of the spray hole 3 =6mm, three reflow grooves 15 are arranged at the bottom of the container 1, the groove width H 1 = 8mm. The clean water (deionized water) flowing out from the water storage tank 13 enters the container 1 after being pressurized by the water inlet pipe 12 and the booster pump 10 and is sprayed out from the water spray hole 14 with a liquid flow with a certain pressure. The reflux tank is collected in the drainage tray, and returns to the water storage tank through the water outlet pipe 6, the filter device 7, and t...

Embodiment 2

[0040] The cleaning device and method are the same as in Example 1. It is used for washing and processing double-fork freeze-dried vaccine rubber stoppers, and the processing volume of each batch is 30kg. Geometric size of rubber stopper: d 1 =19mm; d 2 = 13.5 mm; h 1 = 9.2 mm. Cleaning time is 25 minutes. Table 2 compares the test results of insoluble impurity particles on the surface of the obtained product with those of the rolling cleaning device and method.

[0041] particle size

PUM

| Property | Measurement | Unit |

|---|---|---|

| Geometry | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com