Electric imaging system using organic laser matrix radiation area light valve

An electrical imaging and laser technology, applied to the structure/shape of lasers, laser components, and optical resonators, to achieve the effect of suppressing the appearance of laser spots and improving image uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] To facilitate understanding, where possible, identical reference numerals have been used to designate identical elements that are common to the figures.

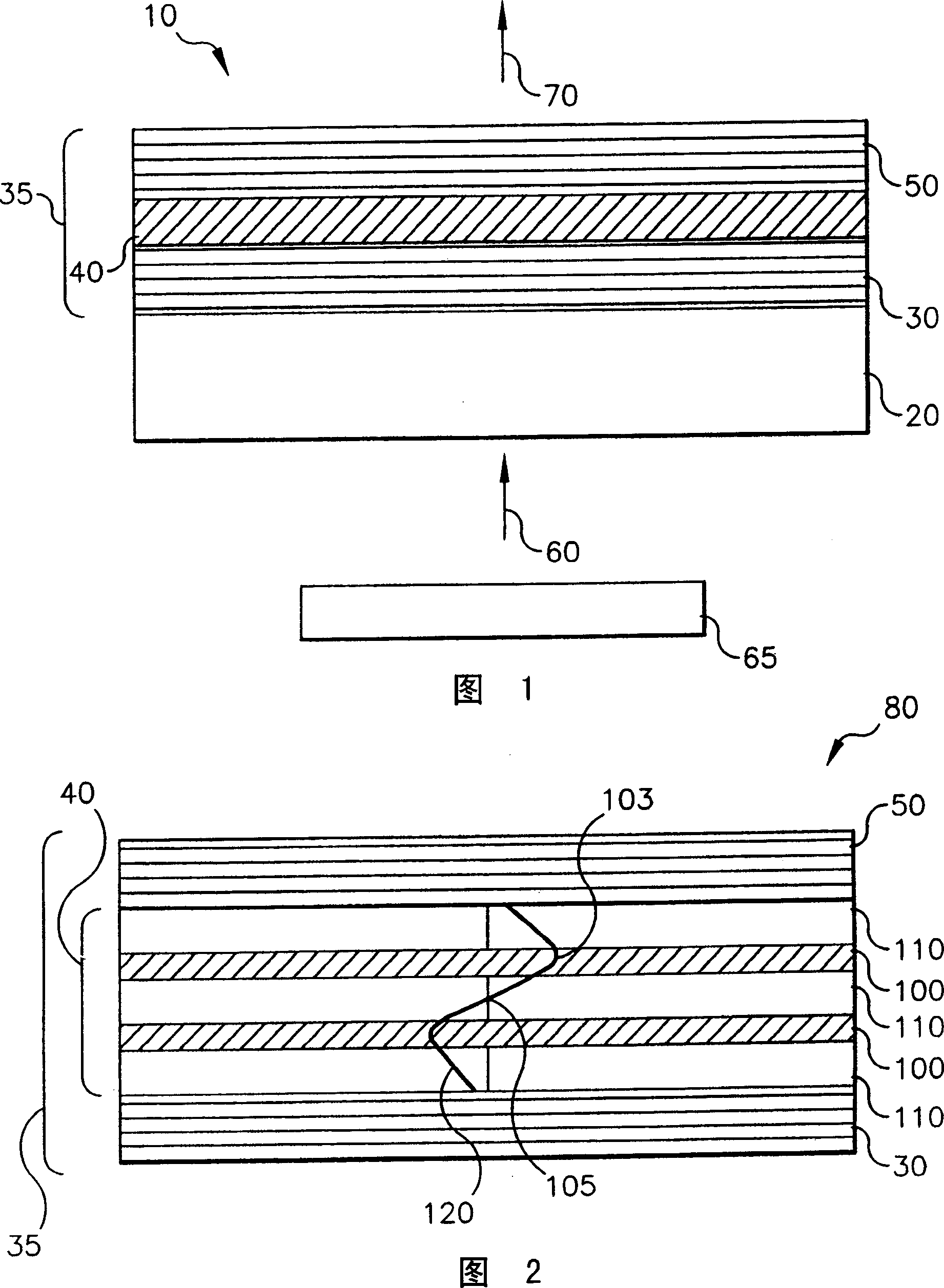

[0035] FIG. 1 shows a schematic diagram of a vertical cavity organic laser device 10 . Substrate 20 can be transparent or opaque, depending on the desired direction of optical pumping and laser emission. The transparent substrate 20 can be transparent glass, plastic or other transparent materials such as sapphire. Alternatively, opaque substrates including, but not limited to, semiconductor materials (eg, silicon) or ceramic materials may be used where optical pumping and emission occur through the same surface. An organic laser thin film structure 35 comprising a first dielectric stack 30 followed by an organic active region 40 and a second dielectric stack 50 is deposited on the substrate. The pump beam 60 emitted by the photon source 65 optically pumps the vertical cavity organic laser device 10 through the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com