Angular enclosed battery

A rectangular battery, sealed technology, applied in the direction of battery pack components, battery box/outer, primary battery to battery grouping, etc., can solve the problems of high internal resistance, long connection path, large loss, etc., to reduce connection resistance , easy to connect, ensure the effect of insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

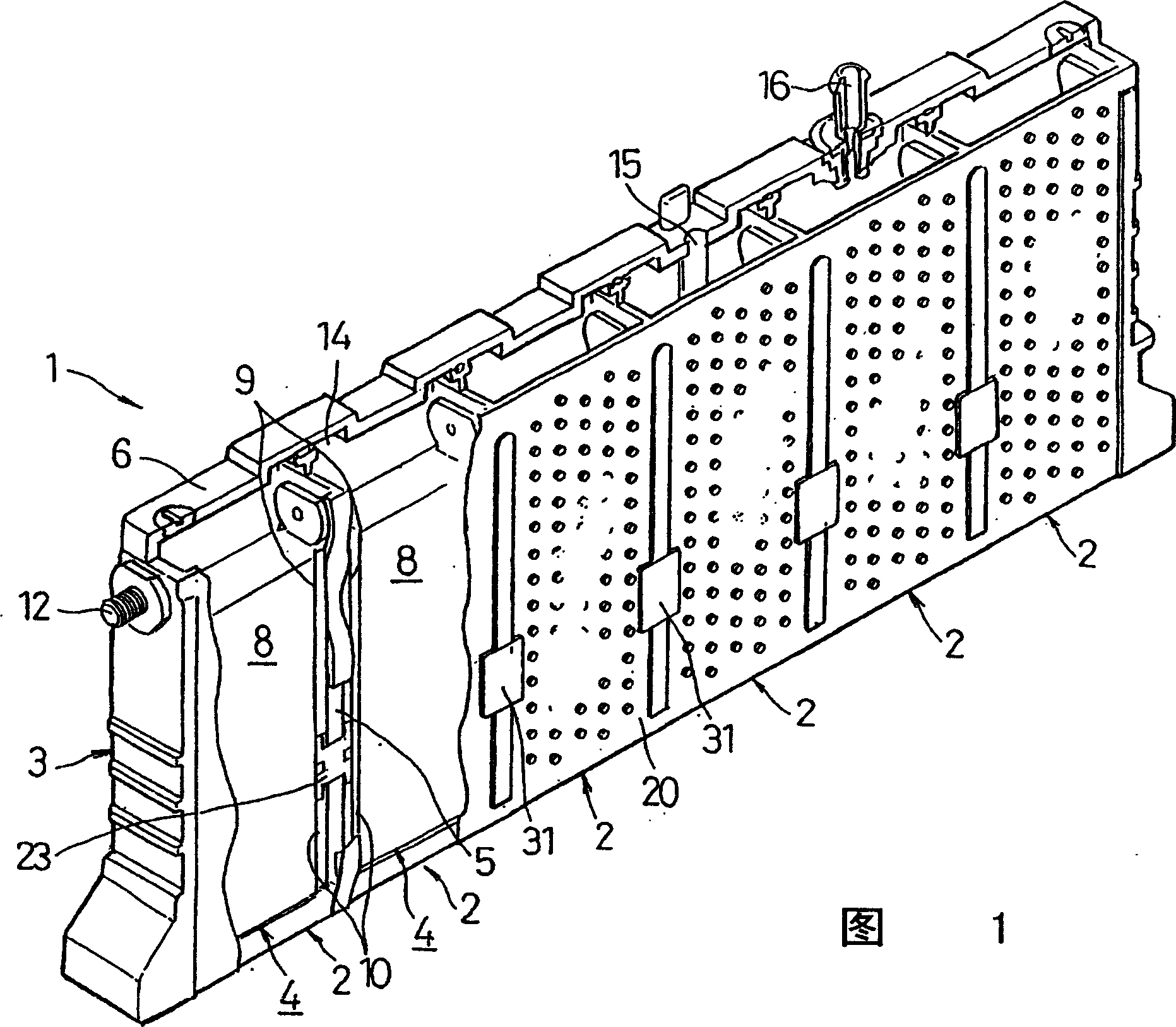

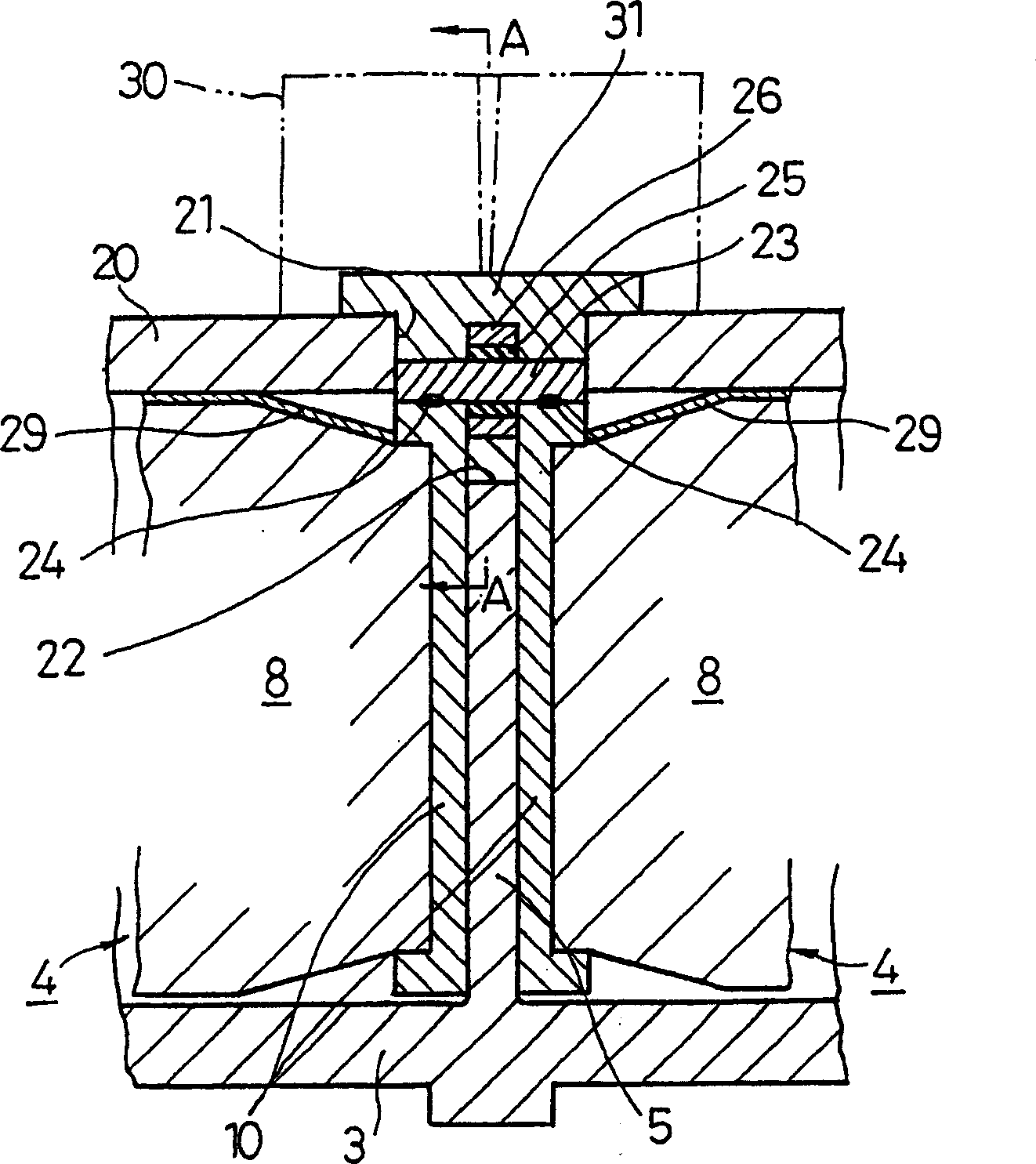

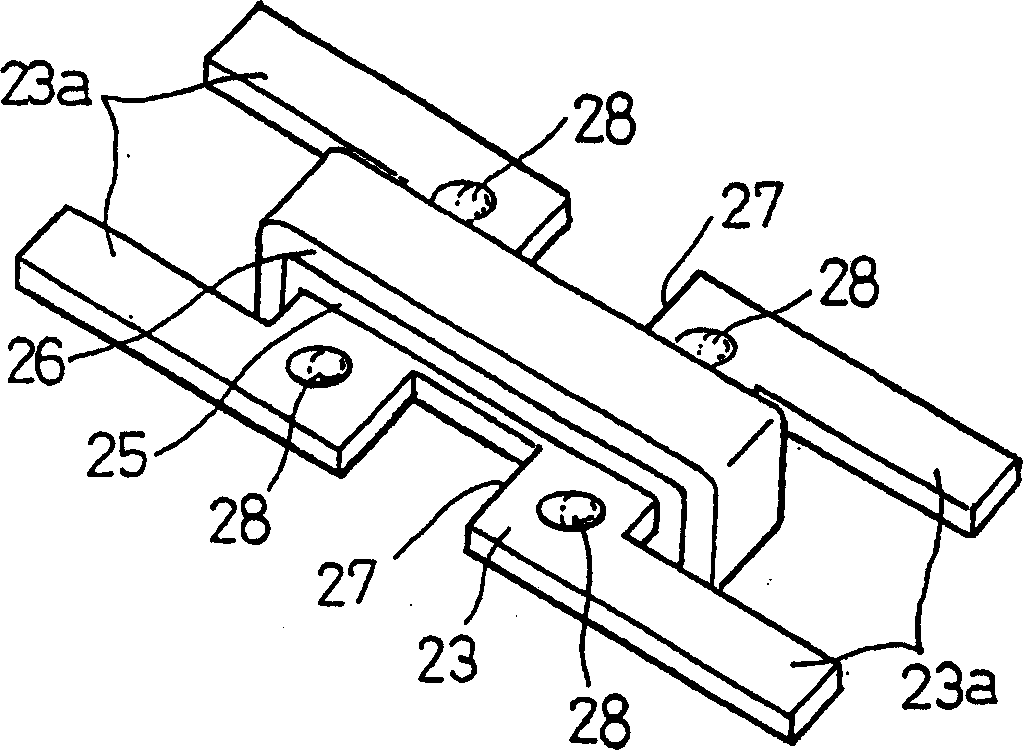

[0055] Hereinafter, refer to Figure 1~ Figure 6 The first embodiment of the rectangular sealed battery of the present invention will be described. However, for the reference Figure 22 , 23 The same components of the conventional technology described are marked with the same reference signs, and the differences are mainly described.

[0056] In FIG. 1, the rectangular battery tank 3 of the rectangular sealed battery 1 of the present embodiment is formed by using a plurality of rectangular parallelepiped battery tanks 4 with narrow short sides and wide long sides as partition walls 5. Shared, so as to be integrally connected to each other. The rectangular battery tank 3 is made of a synthetic resin material such as a composite of PP and PPE, which is resistant to electrolyte. The electrode plate group 8 to which the current collector 10 (10a, 10b) is connected on both sides is accommodated in each battery tank 4 together with electrolyte solution, and the unit cell 2 is comprised....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com