LED device and portable telephone, digital camera and LCD apparatus using the same

A LED device and device technology, applied in the direction of electric solid-state devices, semiconductor devices, chemical instruments and methods, etc., can solve the problems of narrow peak emission width, difficulty in obtaining bright white light with color reproduction characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

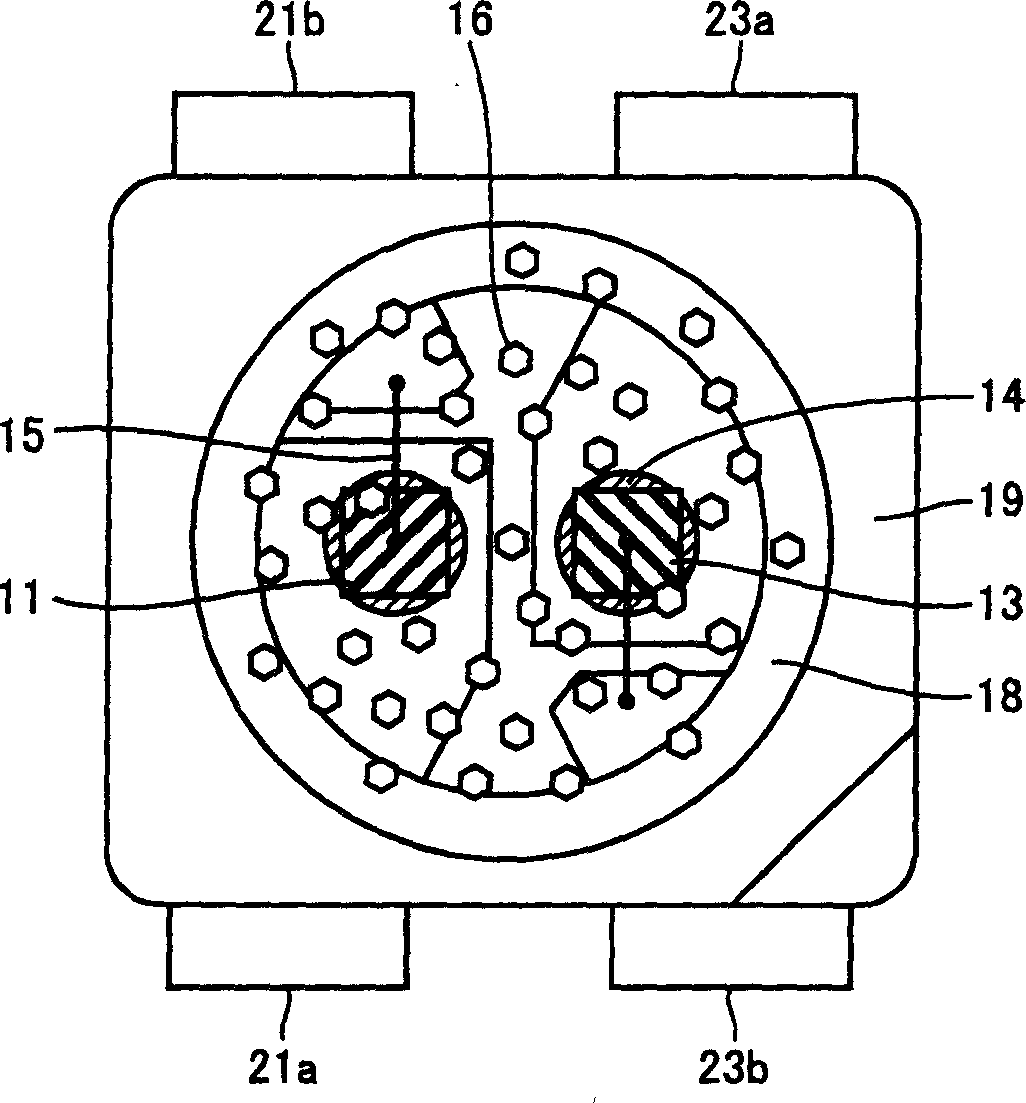

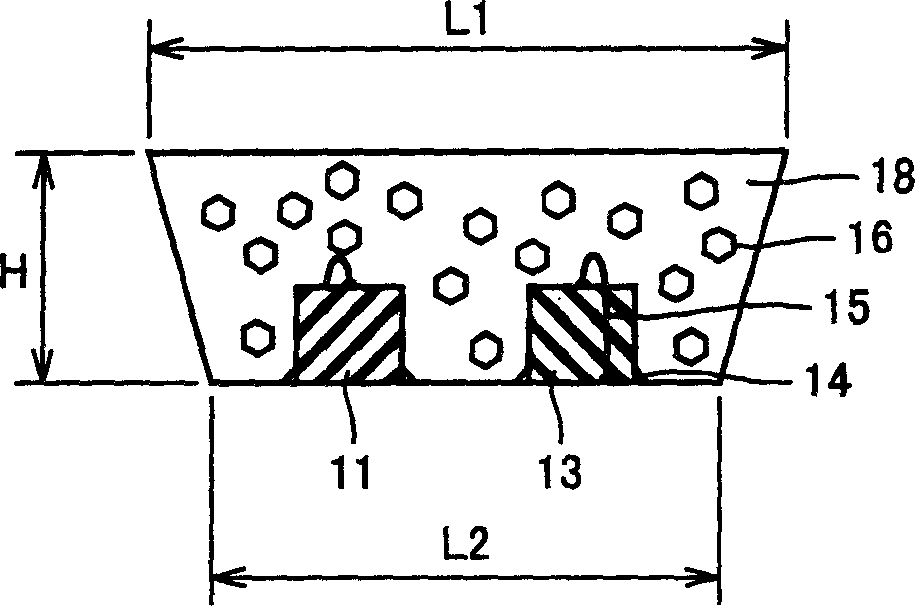

[0057] refer to Figure 1A and 1B , use InGaN with a peak emission wavelength of 460nm as the blue light emitting element, InGaN is on the SiC substrate, the electrodes are arranged in a P / N vertical relative arrangement, and AlGaInP with a peak emission wavelength of 624nm and a P / N vertical relative arrangement is used as the The red light emitting element 13 uses SrGa with an average particle diameter of 8 μm 2 S 4 : Eu as the green fluorescent substance 16. The terminal electrodes 21a, 21b, 23a, and 23b are Cu alloys, and for better wire bonding, the Cu alloys are plated with Au plating. Ag paste was used as the conductive adhesive 14 , and Au wire was used as the bonding wire 15 . The light-transmitting resin 18 is thermosetting epoxy resin (specific gravity: 1.2).

[0058] Figure 1A and 1B The shown LED device was fabricated through the following steps. First, the n-electrodes of the blue light emitting element 11 and the red light emitting element 13 are bonded t...

Embodiment 2

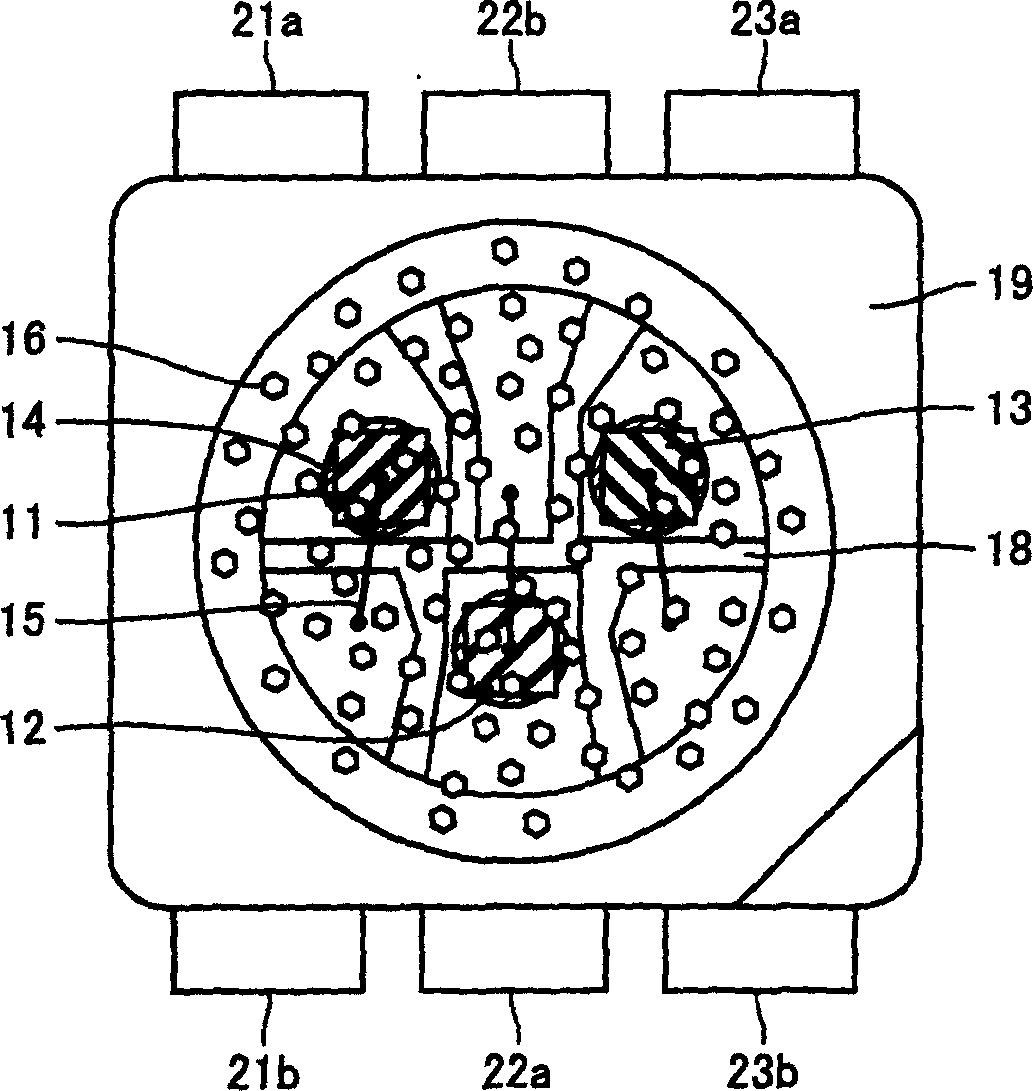

[0065] refer to Figure 2A and 2B , using GaN with a peak emission wavelength of 405nm and electrodes in a P / N vertically opposite arrangement as the ultraviolet / violet light emitting element 12 . The red light emitting element 13, the green fluorescent substance 16, the terminal electrodes 21a, 21b, 23a, and 23b, the conductive adhesive 14, the bonding wire 15, and the light-transmitting resin 18 are the same as those used in Embodiment 1. The LED device was fabricated by the steps similar to that of Example 1.

[0066] In this LED device, when only using 35mA current to drive the red light emitting element 13, the axial luminous intensity of the red light obtained is 1.1cd; For fluorescence, blue-green light with an axial luminous intensity of 1.1cd is obtained. When only 35mA current is used to drive the ultraviolet / violet light emitting element 12, green light with an axial luminous intensity of 2.0cd from the green fluorescent substance 16 is obtained. , and when these...

Embodiment 3

[0068] Adopt and embodiment 2 similar ways to manufacture LED device, just use SrAl 2 o 4 :Eu instead of SrGa 2 S 4 : Eu is used as the green fluorescent substance 16, and 0.1 g of the green fluorescent substance is kneaded in every 1 g of light-transmitting resin.

[0069] In this LED device, when only 35mA current is used to drive the red light emitting element 13, the axial luminous intensity of the obtained red light is 1.1cd; when only 35mA current is used to drive the blue light emitting element, the green fluorescent substance is hardly excited. Obtained is the blue light with an axial luminous intensity of 0.5cd. When only 35mA current is used to drive the ultraviolet / violet light emitting element 12, what is obtained is the green light with an axial luminous intensity of 1.4cd emitted by the green fluorescent substance 16, and when these When the light-emitting elements are all driven by a current of 35 mA, white light with an axial luminous intensity of 3.0 cd and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com