Temperature induced emissivity reversibly variable material

A technology of emissivity and mass percentage, applied in the field of material science and engineering, can solve the problems of complex structure, high price, no materials, etc., and achieve the effect of reducing environmental pollution, saving fossil energy, huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

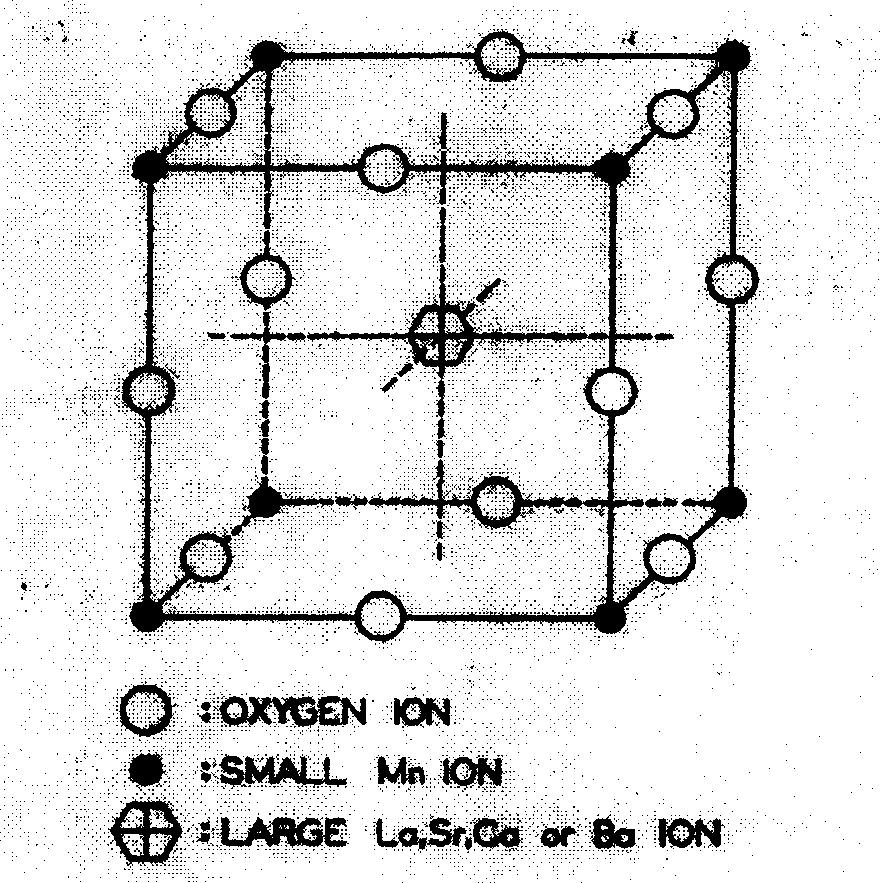

Method used

Image

Examples

Embodiment 1

[0038] The material ratio of temperature-induced emissivity reversible change is:

[0039] La 2 o 3 15%

[0040] CaO 10%

[0041] mn 3 o 4 70%

[0042] Na 2 O, K 2 O 5%

[0043] The total amount meets 100%

[0044] Weigh each component material according to the above-mentioned ratio, and grind it with a grinder, and its fineness is not more than 5% based on the sieve balance of a 0.080mm square hole sieve. Then the ground powder was pressed into tablets and fired in air at 950°C for 14 hours. After taking it out for cooling, crushing, re-grinding, tableting, firing in air at 1200°C for 20 hours, and cooling to room temperature with the furnace, the material of the present invention is obtained. The emissivity of the temperature-induced emissivity reversible change material changes from 0.90-0.92 above 340K to 0.66-0.86 below 340K, the range of change is about 0.26, the transition temperature is about 340K, and the emissi...

Embodiment 2

[0046] The material ratio of temperature-induced emissivity reversible change is:

[0047] La 2 o 3 5%

[0048] SrCO 3 5%

[0049] mn 3 o 4 75%

[0050] Na 2 O, K 2 O 15%

[0051] The total amount meets 100%

[0052] Weigh each component material according to the above-mentioned proportioning, and use a grinder to grind, and the fineness is not more than 3% based on the sieve balance of a 0.080mm square hole sieve. Then the ground powder was pressed into tablets and fired in air at 850°C for 15 hours. After taking it out for cooling, crushing, re-grinding, tableting, firing in air at 1150°C for 20 hours, and cooling to room temperature with the furnace, the material of the present invention is obtained. The emissivity of the temperature-induced emissivity reversible change material changes from 0.85-0.86 above 320K to 0.58-0.59 below 320K, the range of change is about 0.27, the transition temper...

Embodiment 3

[0054] The material ratio of temperature-induced emissivity reversible change is:

[0055] La 2 o 3 25%

[0056] SrCO 3 10%

[0057] mn 3 o 4 50%

[0058] CaO 15%

[0059] The total amount meets 100%

[0060] Each component material is weighed according to the above-mentioned proportioning, and a grinder is used for grinding, and its fineness is not more than 2% based on the sieve balance of a 0.080mm square hole sieve. Then the ground powder was pressed into tablets and fired in air at 1100°C for 5 hours. After taking it out for cooling, crushing, re-grinding, tableting, firing in air at 1250°C for 10 hours, and cooling to room temperature with the furnace, the material of the present invention is obtained. The emissivity of the temperature-induced emissivity reversible change material changes from 0.80-0.82 above 296K to 0.46-0.64 below 296K, the range of change is about 0.36, the transitio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com