Method for changing inclination angle of hydride gas phase transverse epitaxy GaN film

A hydride vapor phase and lateral epitaxy technology, which is applied to electrical components, gaseous chemical plating, coating, etc., can solve the problem of high dislocation density of GaN epitaxial layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

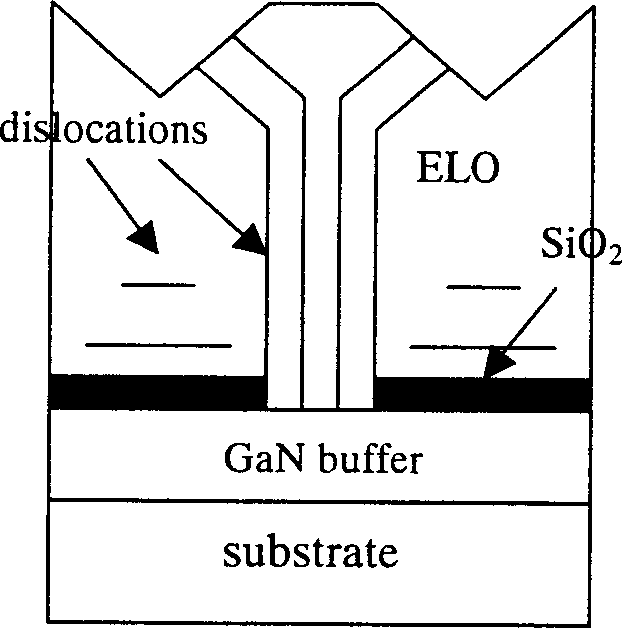

[0014] The main method of the hydride vapor phase epitaxy device and the lateral epitaxial growth technology used in the present invention is to directly introduce a certain amount of HCl into the substrate surface, and by changing the chemical reaction balance in the reaction zone, the tilt angle of the GaN lateral epitaxial film finally changes. Change or even eliminate to obtain a high-quality flat GaN film.

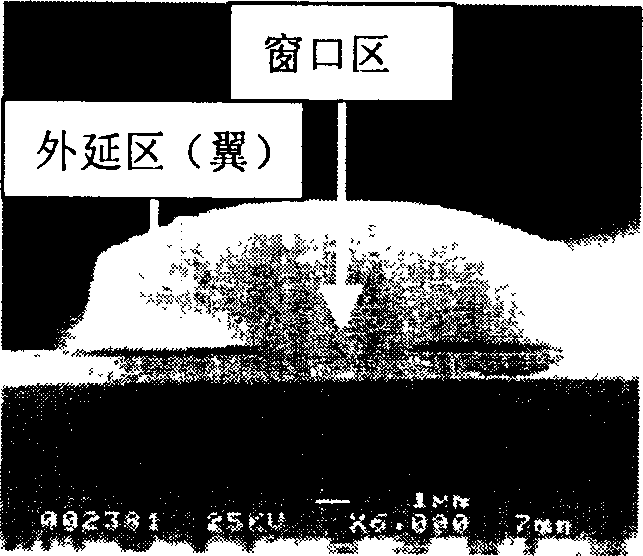

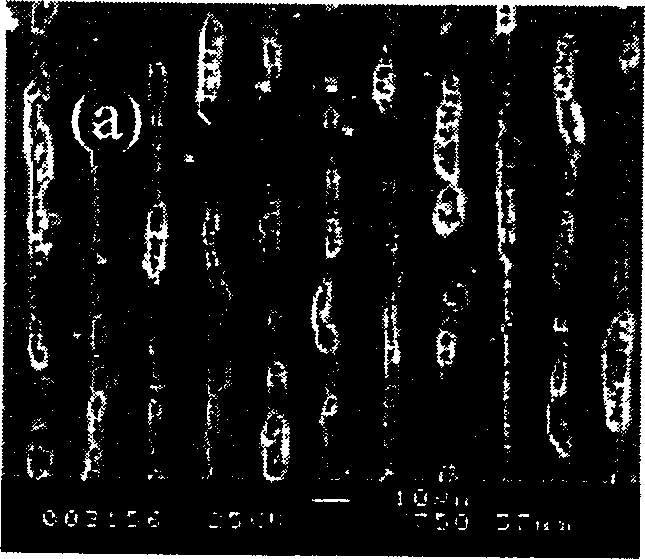

[0015] The growth conditions are: the lateral epitaxial substrate is GaN / sapphire; the window area / SiO 2 The ratio of the mask area is 2:20, SiO 2 The mask orientation is along the GaN direction. NH 3 The flow rate was 600 sccm, and the HCl flow rate to generate GaCl was 1 sccm. The HCl flow rate added directly to the substrate was 4-10 sccm. figure 2 The example of the photograph is a flow rate of 5 sccm of HCl added directly to the substrate. The lateral epitaxial growth temperature is 1050°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com