Method of forming high-loft spunbond non-woven webs and product formed thereby

A non-woven fiber web, bulking technology, used in non-woven fabrics, textiles, papermaking, textiles, etc., can solve problems such as insufficient, and achieve the effect of improving physical properties and reducing basis weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

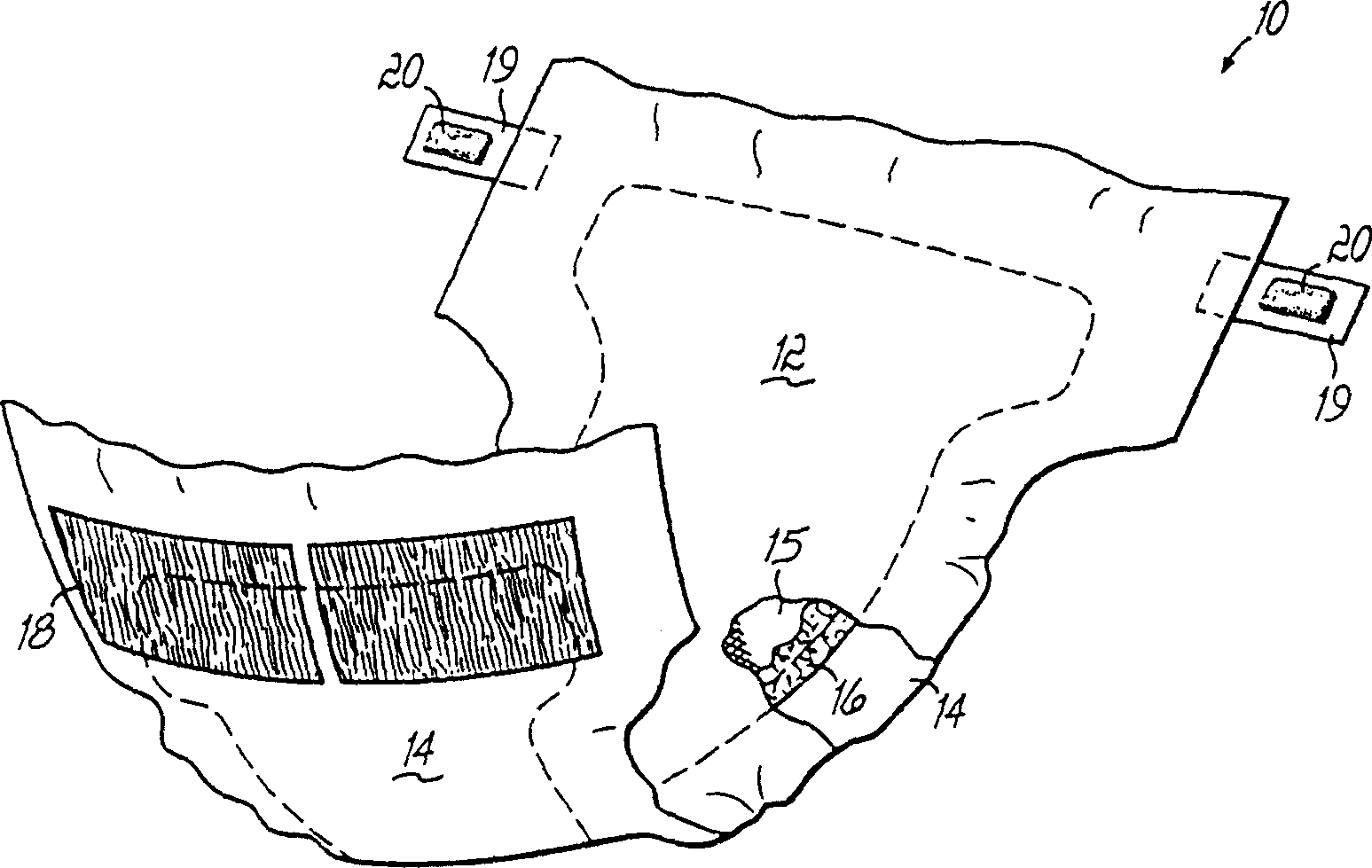

[0018] The present invention is concerned with multicomponent filaments and their incorporation into various components of sanitary articles. refer to image 3 Generally, the disposable hygiene article 10 comprises a topsheet 12, a backsheet 14 and a fluid storage layer 16 between the topsheet 12 and the backsheet 4. The topsheet 12 transfers aqueous body fluids, such as urine, into the fluid storage layer 16 . The hygiene article 10 includes a fluid acquisition and transfer layer 15 between the fluid storage layer 16 and the topsheet 12, which enables the fluid capacity of the base fluid storage layer 16 to be fully utilized. The fluid acquisition and transfer layer 15 is positioned between the topsheet 12 and the fluid storage layer 16 in the hygiene article. The fluid acquisition and transfer layer 15 distributes aqueous body fluids transferred from the topsheet 12 in the x-y dimension. The term "X-Y dimensional direction" as used herein means a plane normal to the Z dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com