Method for processing waste products and corresponding processing plant

A technology of treatment equipment and waste treatment, applied in biological sludge treatment, solid waste removal, combustion methods, etc., can solve the problems of complex exhaust gas, high cost, large space, etc., and achieve the effect of compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

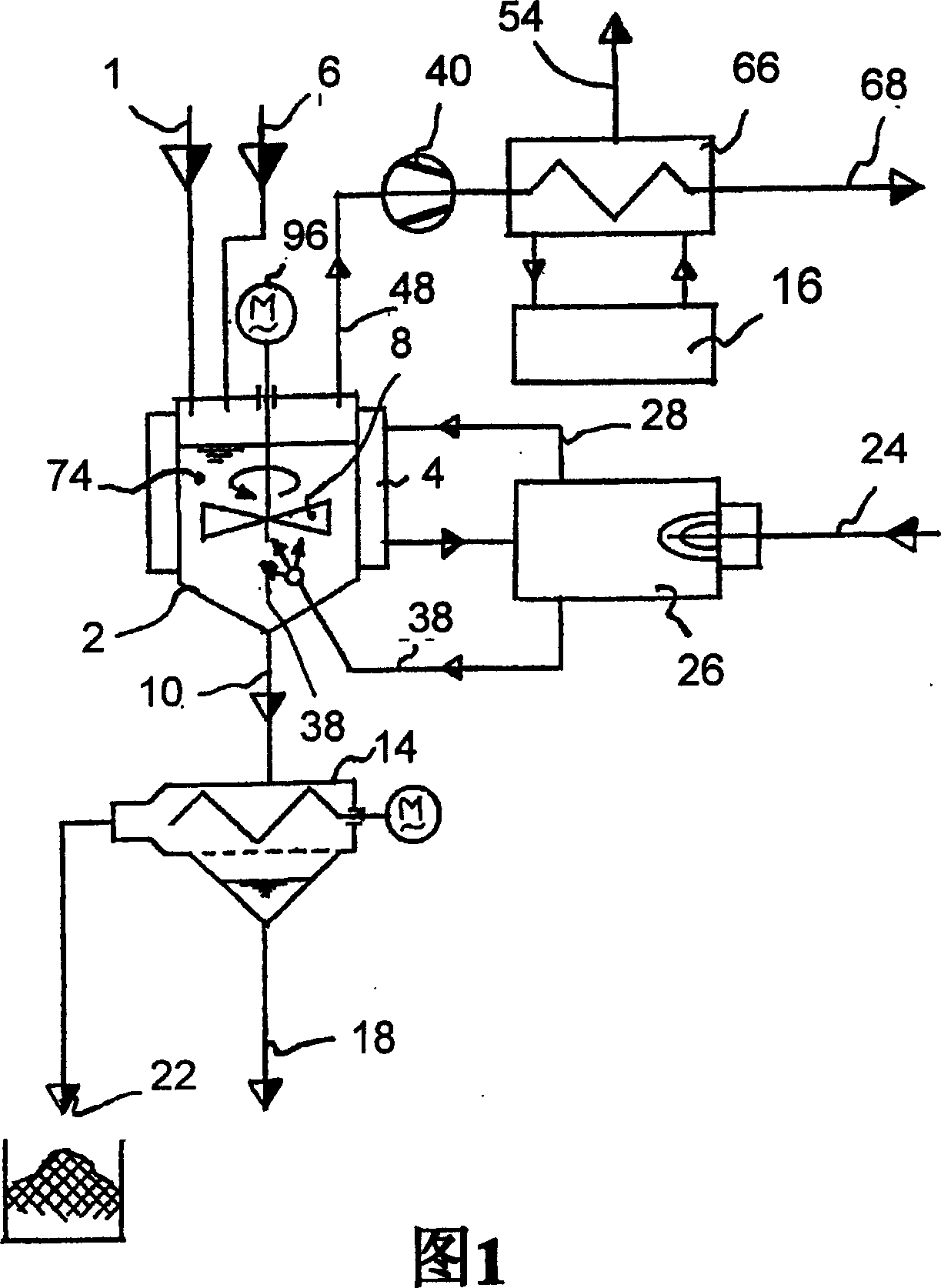

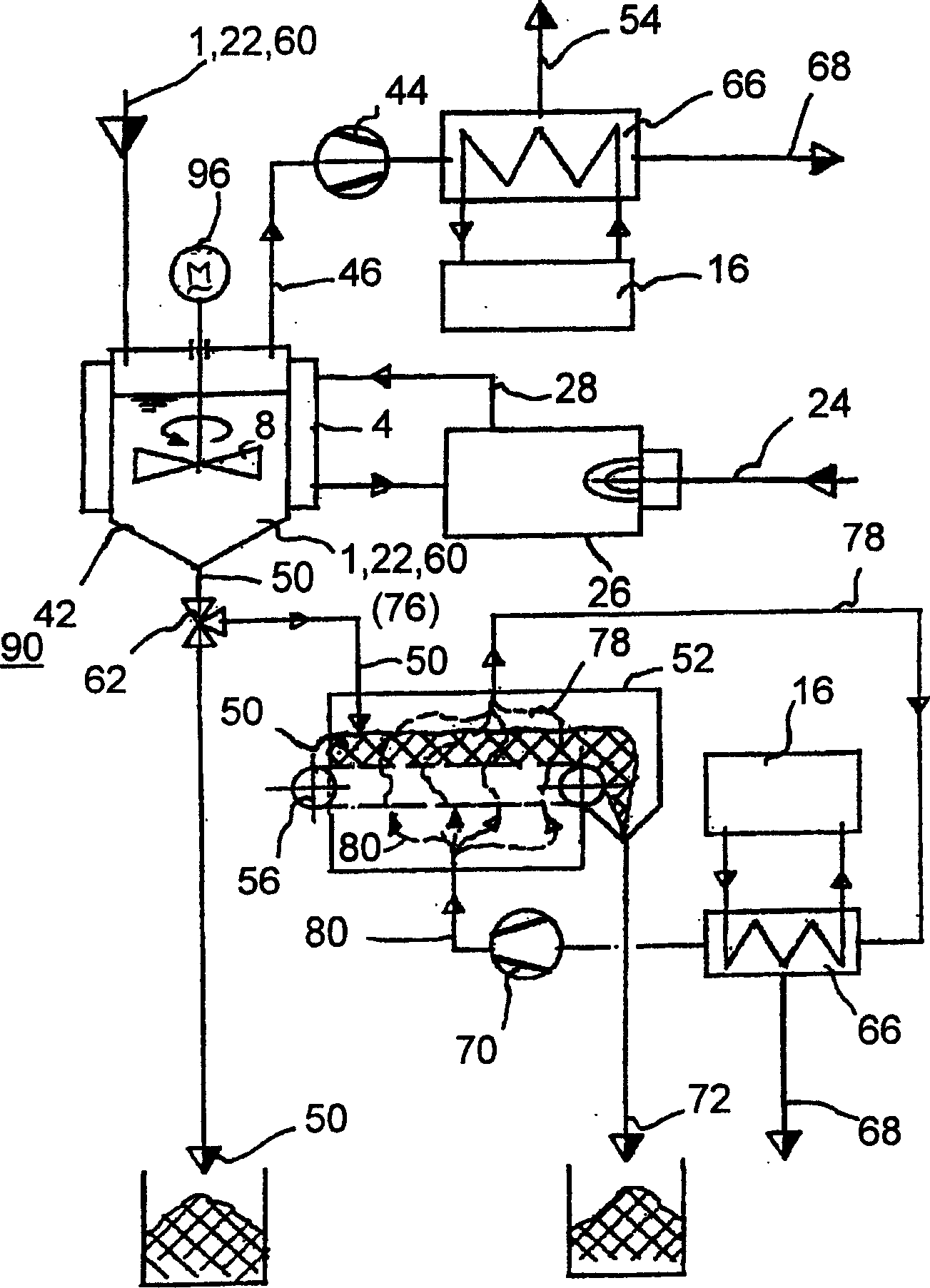

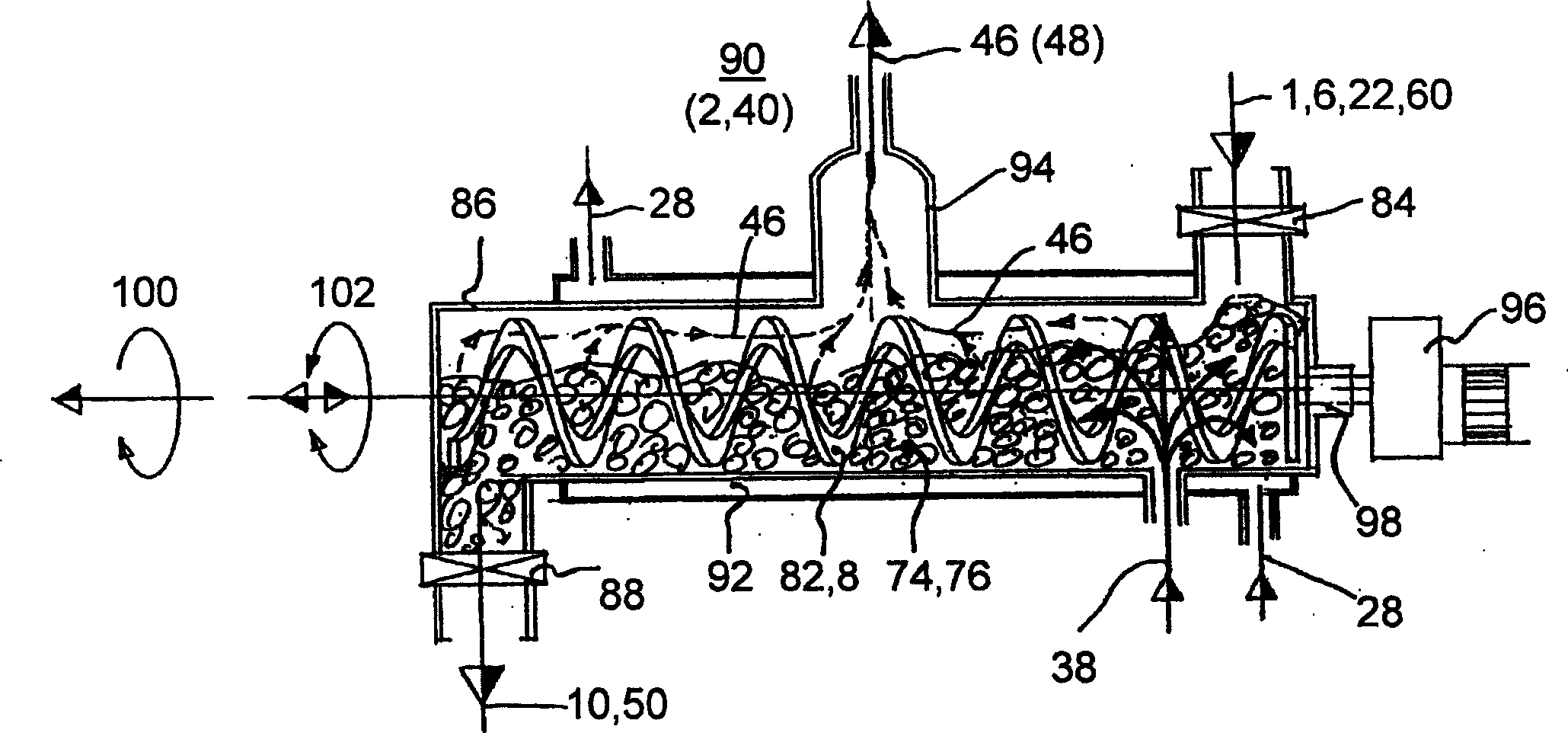

[0044] Figure 1 exemplarily shows the rationale for the minimum required equipment for the boiling extraction process to treat organically contaminated waste such as, for example, residual waste, food boxes, waste from the food industry, vegetables and other recyclables Organic waste, sewage and fermentation sludge, biological residues such as mash from beverage production.

[0045] Organic pollutants 1 are supplied to reactor 2 and diluted with fresh water or circulating fluid 6 . The waste suspension 74 is mixed with the liquid with the help of the stirring device 8 and transported. Heat is provided by heating jacket 4 to reach the boiling point temperature.

[0046] In order to accelerate the heat treatment, it is also possible to continuously introduce pressurized steam 38 directly into the suspension 74 and / or via an upstream heating belt not shown in detail.

[0047] The major part of this residual waste consists mostly of short-chain compounds adsorbed onto the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com