Adsorption stripping method for removing ethene and carbon dioxide from mixed gas

A mixed gas, adsorption separation technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of high cost and achieve the effect of large adsorption surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

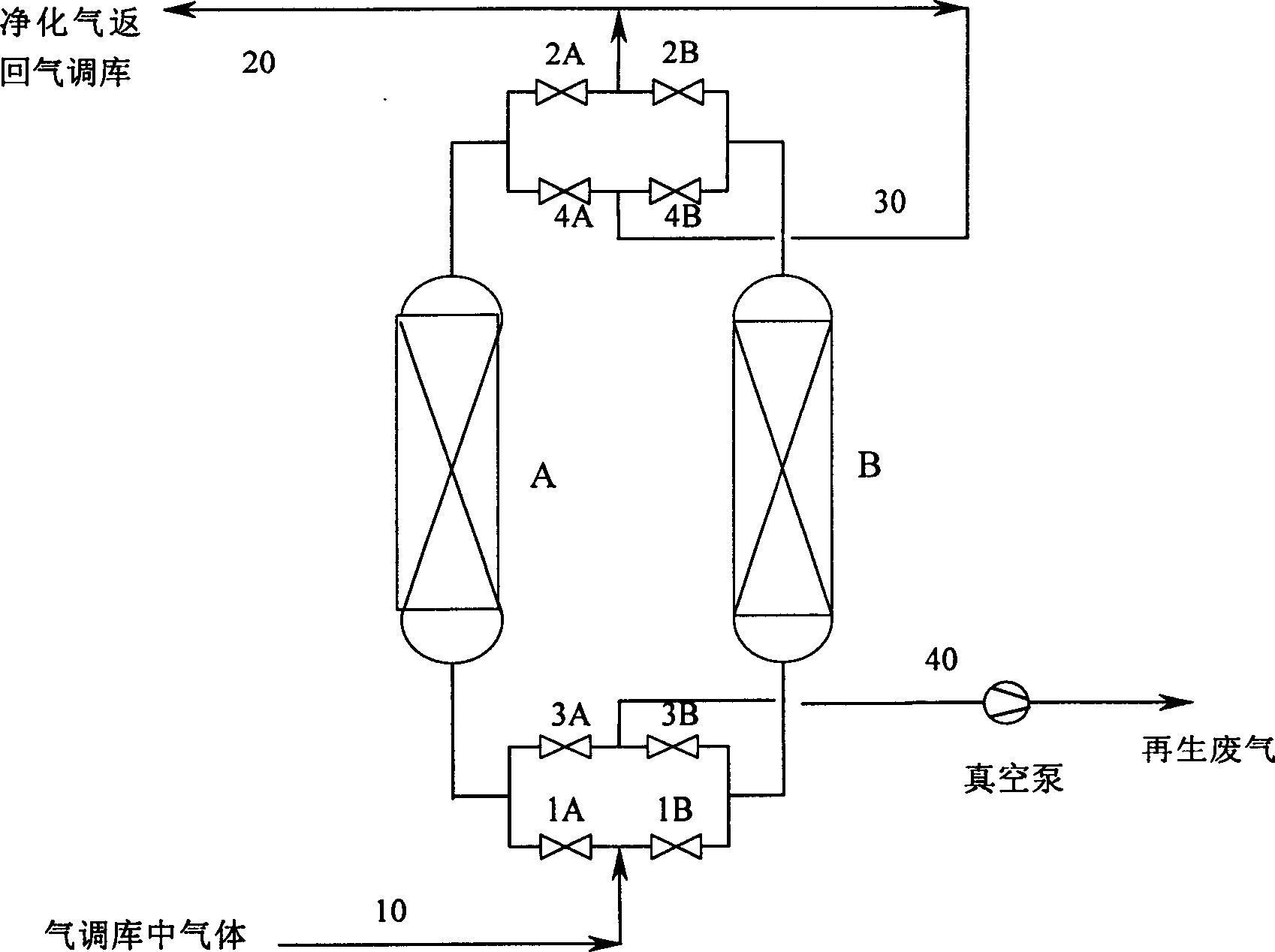

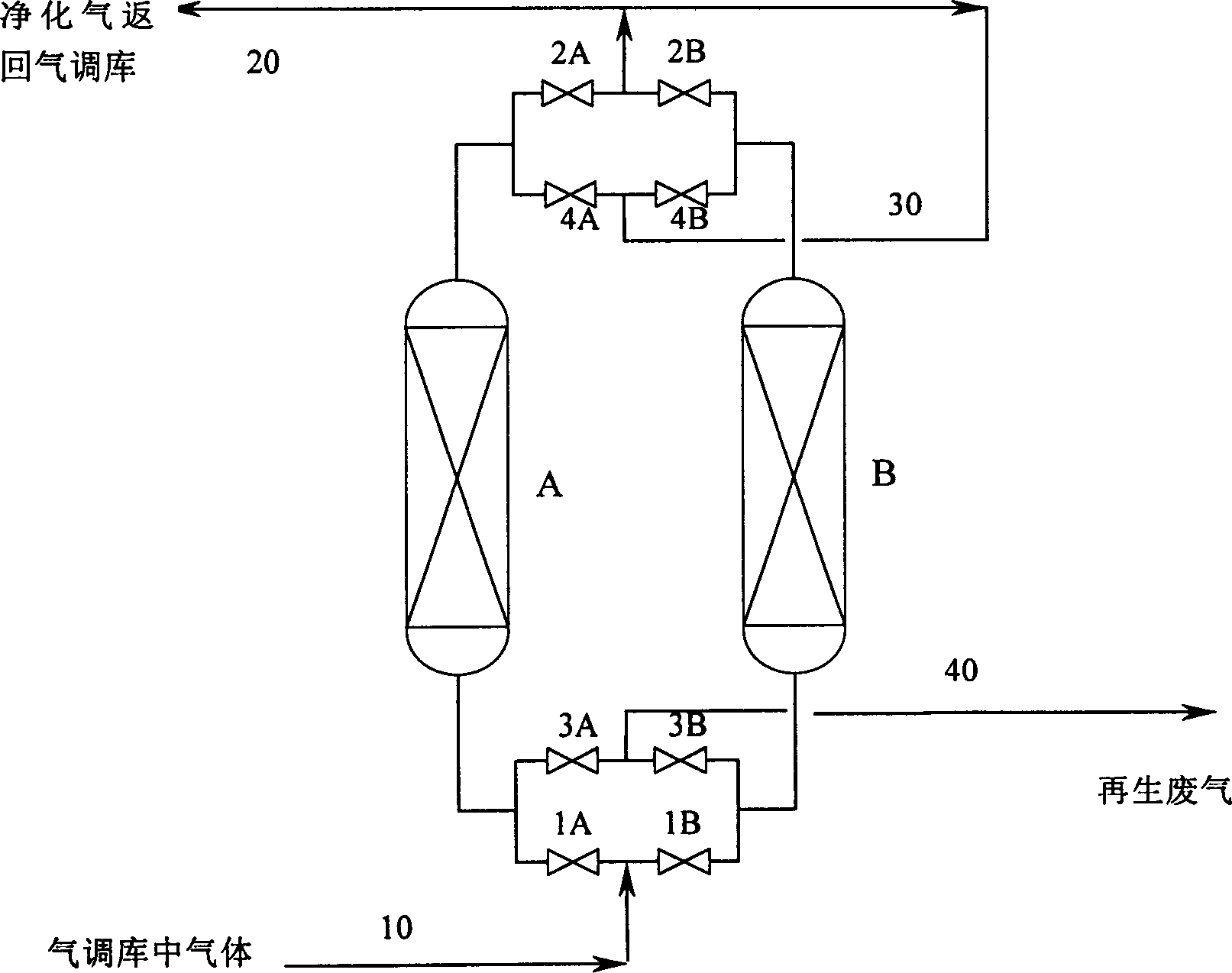

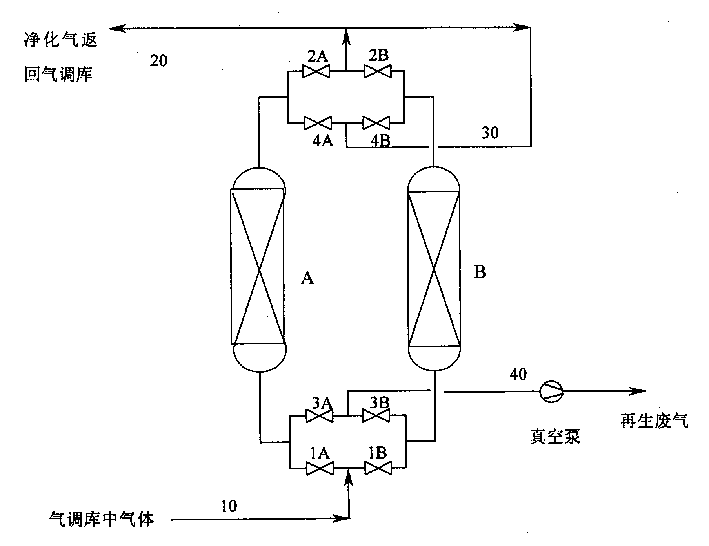

Method used

Image

Examples

Embodiment 1

[0038] 1. Composition and content of gas mixture: H 2 98.95%, C 2 h 4 0.05%, CO 2 1%.

[0039] 2. Composition and content of purified gas: H 2 99.994%, C 2 h 4 0.001%, CO 2 0.005%.

[0040] 3. Purified gas processing capacity: 300Nm 3 / h.

[0041] 4. Number of adsorption beds: 2.

[0042] 5. Adsorbent: activated alumina 10% + activated carbon 20% + fine-pore silica gel 70%.

[0043] 6. Process steps: adsorption, reverse pressure release, flushing, boosting.

[0044] 7. Adsorbent regeneration method: reflux purification gas flushing. Flushing absolute pressure: 0.12MPa.

[0045] 8. Adsorption absolute pressure: 0.15MPa.

Embodiment 2

[0047] 1. Composition and content of gas mixture: H 2 94.99%, C 2 h 4 0.01%, CO 2 5%.

[0048] 2. Composition and content of purified gas: H 2 99.984%, C 2 h 4 0.001%, CO 2 0.015%.

[0049] 3. Purified gas processing capacity: 500Nm 3 / h.

[0050] 4. Number of adsorption beds: 2.

[0051] 5. Adsorbent: activated alumina 10% + activated carbon 90%.

[0052] 6. Process steps: adsorption, reverse pressure release, evacuation, and boost.

[0053] 7. Adsorbent regeneration method: vacuum pump to evacuate. Evacuation absolute pressure: 0.007MPa.

[0054] 8. Adsorption absolute pressure: 0.3MPa.

Embodiment 3

[0056] 1. Composition and content of gas mixture: N 2 89%, C 2 h 4 1%, CO 2 10%.

[0057] 2. Composition and content of purified gas: N 2 99.695%, C 2 h 4 0.005%, CO 2 0.3%.

[0058] 3. Purified gas processing capacity: 300Nm 3 / h.

[0059] 4. Number of adsorption beds: 2.

[0060] 5. Adsorbent: activated alumina 10% + activated carbon 90%.

[0061] 6. Process steps: adsorption, reverse pressure release, evacuation, and boost.

[0062] 7. Adsorbent regeneration method: vacuum pump to evacuate. Evacuation absolute pressure: 0.01MPa.

[0063] 8. Adsorption absolute pressure: 0.4MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com