Method for realizing high speed moving article 3D profile measurement using stroboscopic structure lighting

A moving object, stroboscopic technology, applied in the field of optical three-dimensional sensing, can solve the problem of inability to obtain clear deformed stripes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, working principles and embodiments.

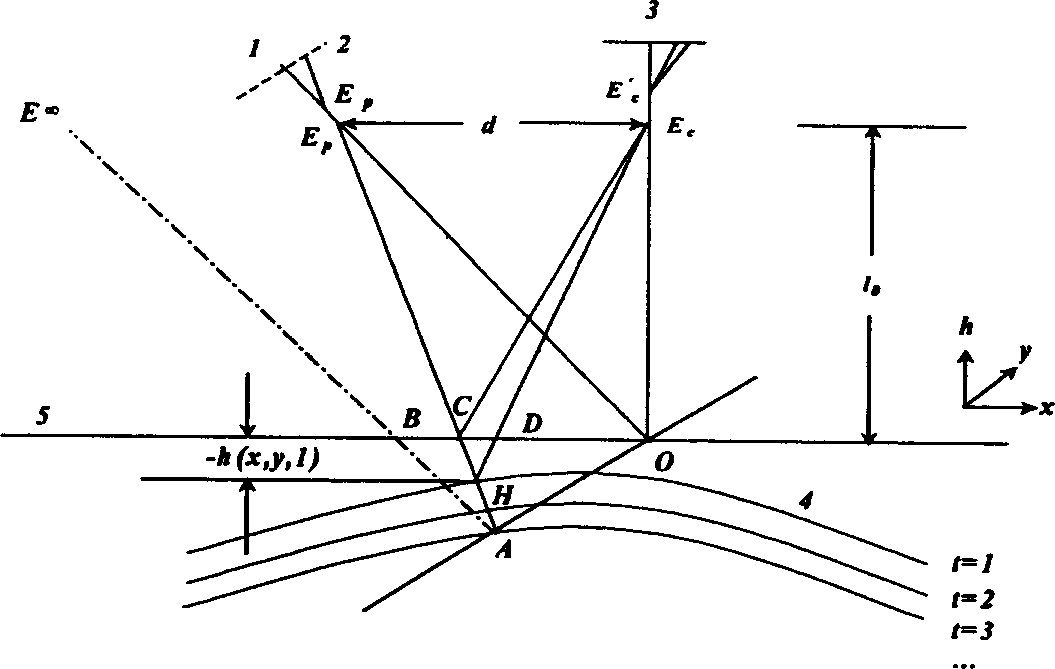

[0026] The optical path adopted by Fourier transform profilometry for dynamic measurement is similar to the optical path of traditional static object surface measurement. figure 1 is the projection optical path of the FTP method, 7 is a projection device, 2 is a projection grating, and 3 is an imaging device, generally using a CCD camera. 4 is the object to be measured. E. p , E' p are the exit pupil and entrance pupil of the projection system, E′ p E. p for its optical axis. E' c ,E c are the exit pupil and entrance pupil of the imaging system, E′ c E. c is the optical axis of the imaging system, and the two optical axes intersect at point O on the reference plane 5 . The grating lines of grating 2 are perpendicular to E p E. c O plane, reference plane and E′ c E. c vertical.

[0027] When a sinusoidal grati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com