Digital controlled laser cutter control method

A numerical control laser and control method technology, which is applied in digital control, laser welding equipment, electrical program control, etc., can solve the problems that the advantages of laser cutting cannot be fully utilized, and optical, mechanical and electrical coordination cannot be controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

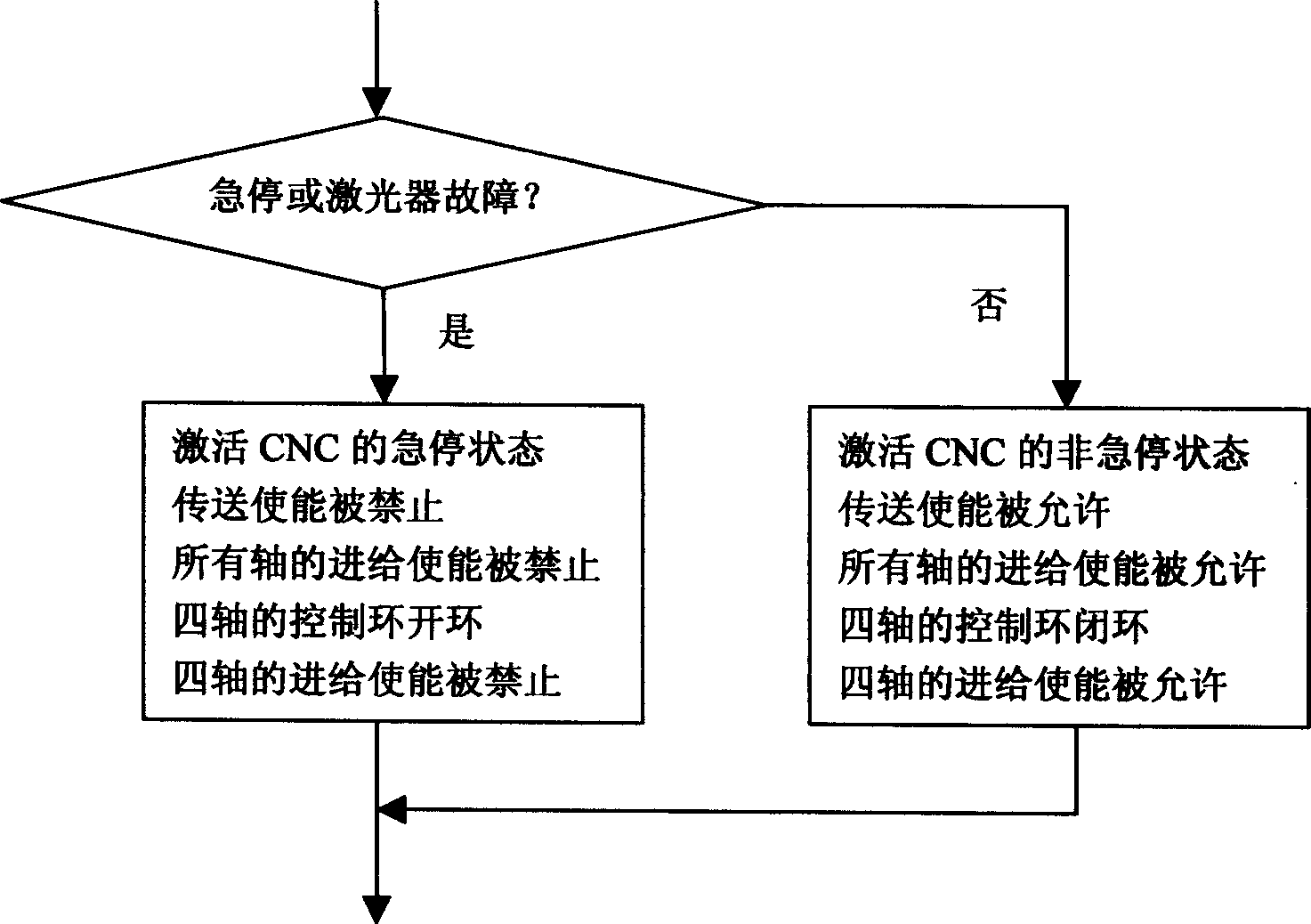

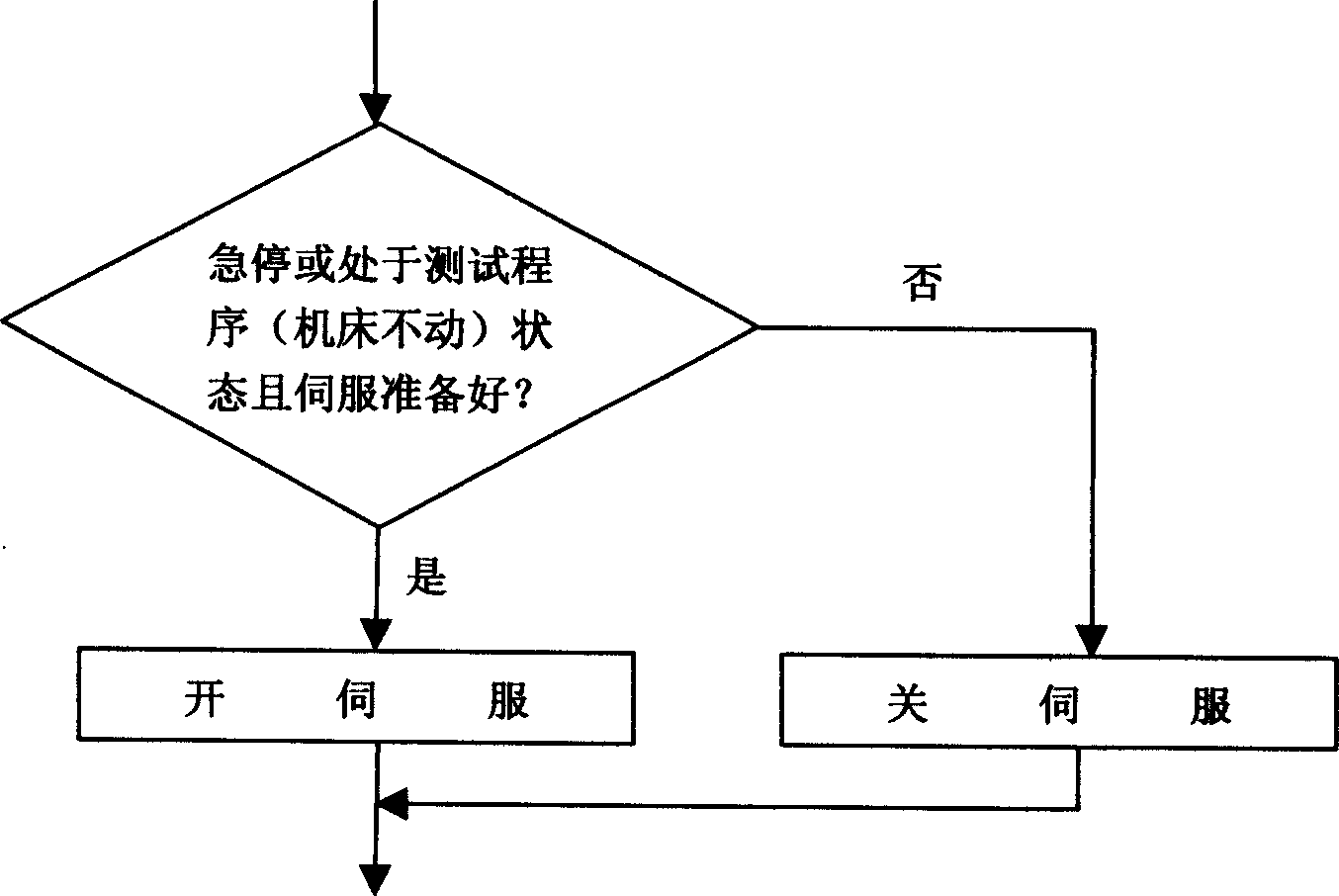

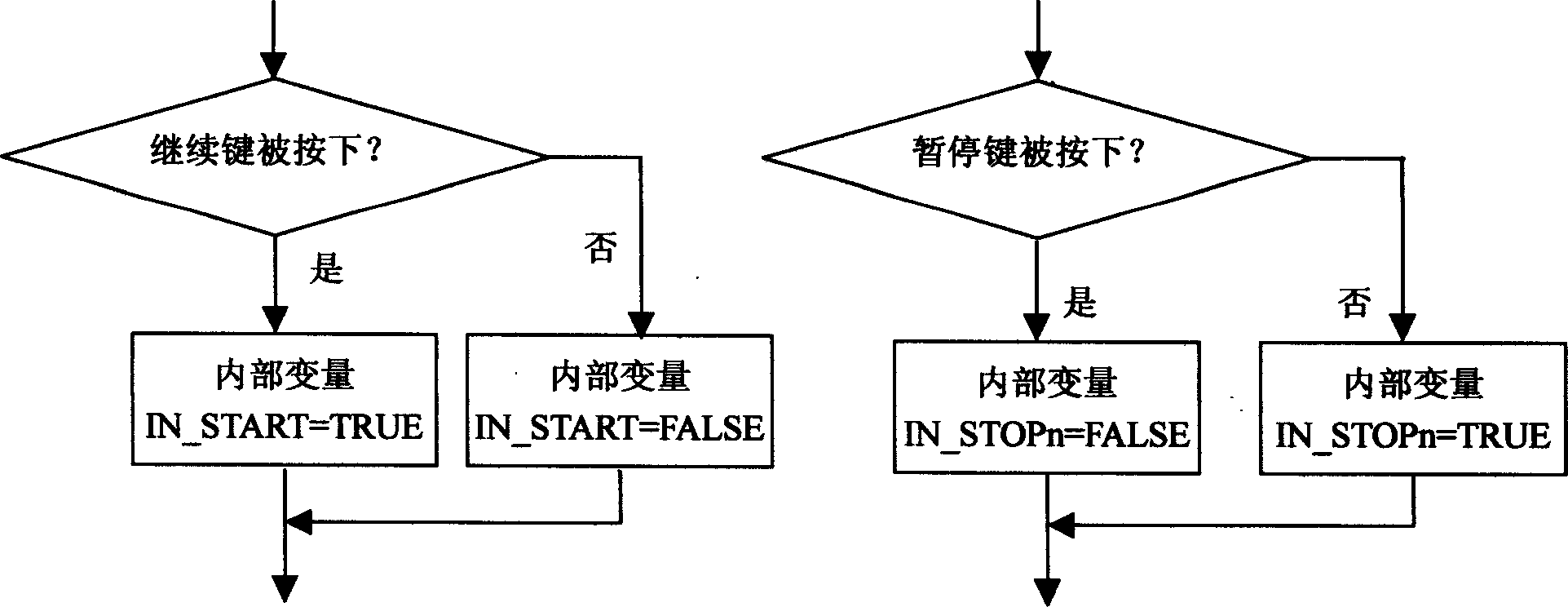

[0021] see Figure 1-8 , the present invention controls the numerical control laser cutting machine, the servo amplifier and the servo motor through the numerical control system of the numerical control laser cutting machine, and the storage digital control program computer in the numerical control system performs the following operations:

[0022] (1) Emergency stop part: receive the emergency stop signal, activate the emergency stop state or non-emergency stop state of the numerical control system.

[0023] The machine tool has three direction axes of X, Y, and Z and a W rotation axis, that is, the four axes that the CNC laser cutting machine needs to be controlled by the CNC system. The control panel and the hand-held part of the CNC system are equipped with a parallel equivalent emergency stop switch. Press the emergency stop switch, the emergency stop relay will act, and the watchdog circuit on the four-axis axis card will not be triggered. At the same time, the emergency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com