Rapid length-measuring cutting process and apparatus for thin wall cylinder

A technology of thin-walled cylinders and cutting devices, which is applied in the direction of shearing devices, pipe cutting devices, manufacturing tools, etc., can solve the problems of large incision damage surface, many process steps, material waste, etc., and achieve excellent performance, accurate size, and economical The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Thin-walled cylinder quick cut-to-length process of the present invention, it comprises the steps:

[0021] 1) The cylinder feed assembly drives the cutting cylinder 3 to the cutting position;

[0022] 2) The cylinder rotating assembly drives the cutting cylinder 3 to rotate;

[0023] 3) The blade rotation assembly drives the cutting blade 4 to cut the cutting cylinder 3 .

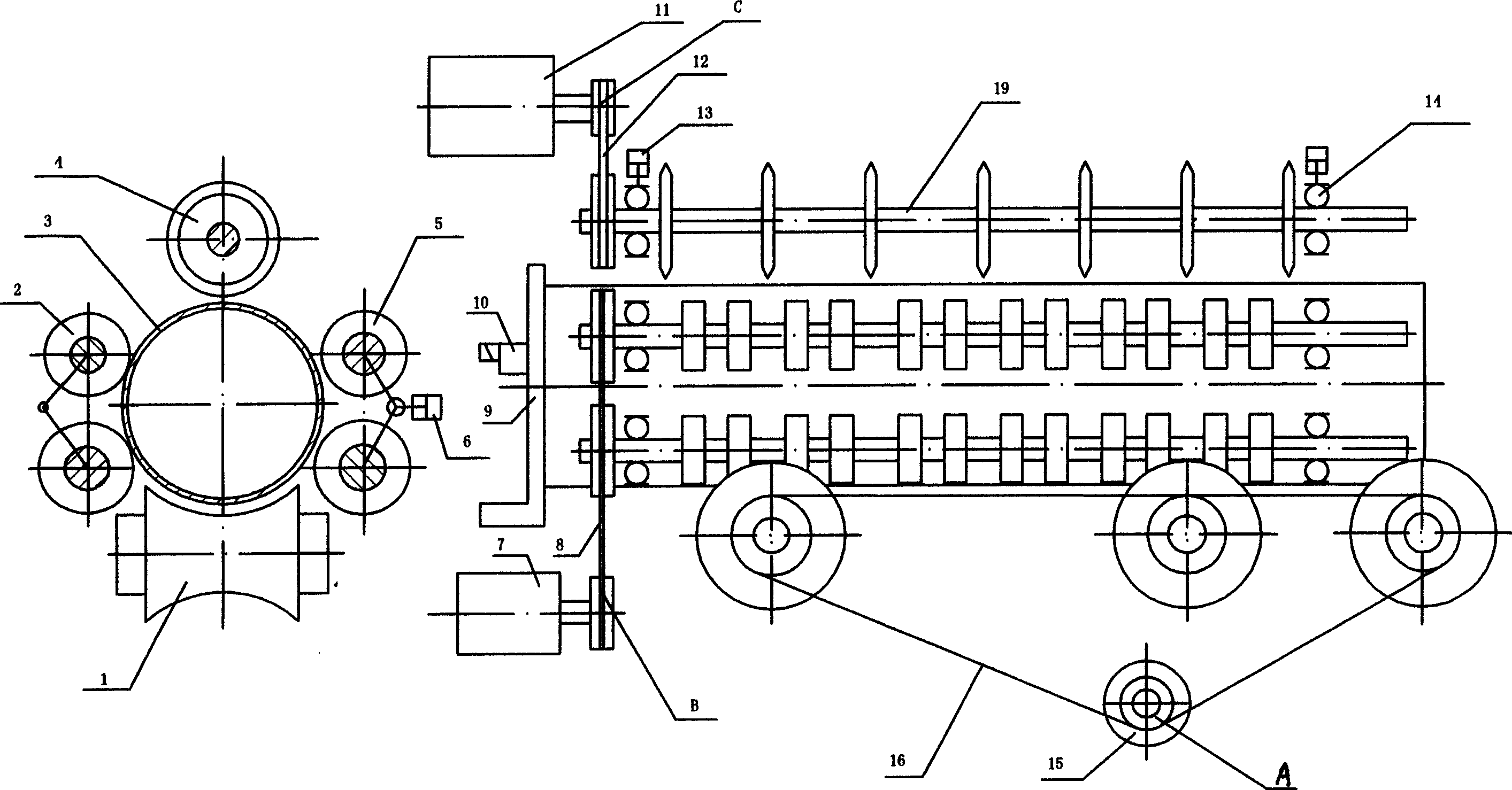

[0024] The thin-walled cylinder fast fixed-length cutting device used in the cutting process of the present invention has a structural schematic diagram as figure 1 As shown, the cylinder feed assembly includes a cylinder feed drive mechanism A and a feed wheel 1, the cylinder rotation assembly includes a cylinder rotation drive mechanism B and a cylinder rotation driving wheel 2, and the blade rotation assembly includes a blade Rotary drive mechanism C and several cutting blades 4, blade rotating shaft 19, wherein the output of cylinder feeding drive mechanism A is connected with the rotating sha...

Embodiment 2

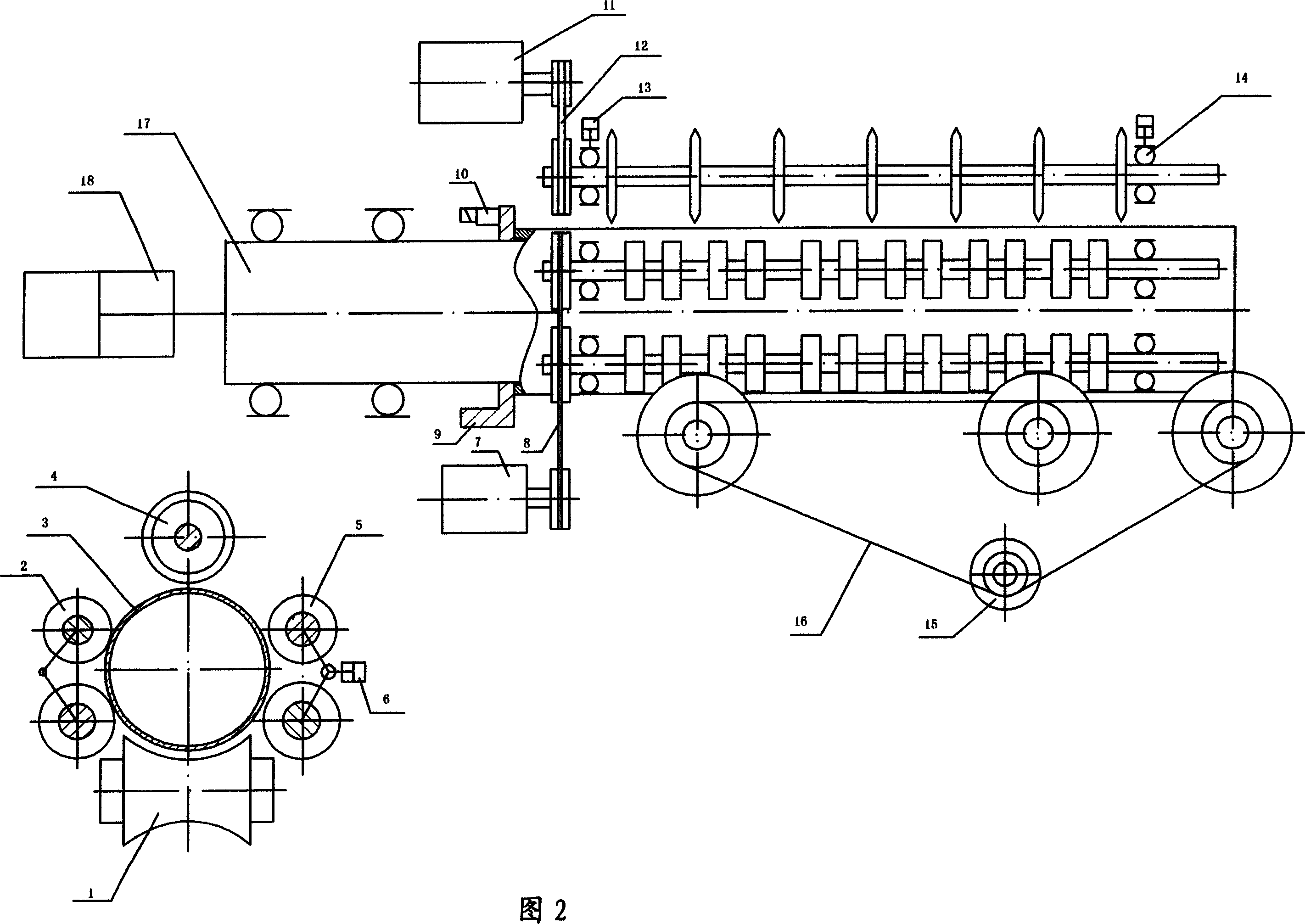

[0033] The thin-walled cylinder fast fixed-length cutting process of the present invention is the same as embodiment 1, and the thin-walled cylinder fast fixed-length cutting device of the present invention is as shown in Figure 2, and it is the structure that has mandrel rolling cutting, and the non-mandrel of embodiment 1 The difference of the rolling cutting structure is that a mandrel 17 driven by a control mechanism 18 is provided in the hollow cavity of the cutting cylinder 3, and the end of the mandrel 17 is supported on the frame. In this embodiment, the control mechanism 18 is an air cylinder.

[0034] The difference between this embodiment and Embodiment 1 in the cutting process is that when the cylinder to be cut is fed into the device, the mandrel 17 is stretched out under the action of the telescopic cylinder 18 to support the inside of the cylinder for rolling cutting. After the cylinder is cut off, the mandrel 17 is retracted under the action of the telescopic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com