Voltage transformer arrangement

A transformer and winding technology, which is applied in the direction of transformers, fixed transformers, transformer/inductor cores, etc., can solve the problems of limited application of transformers, save labor and manufacturing costs, simplify manufacturing procedures, and improve electrical safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

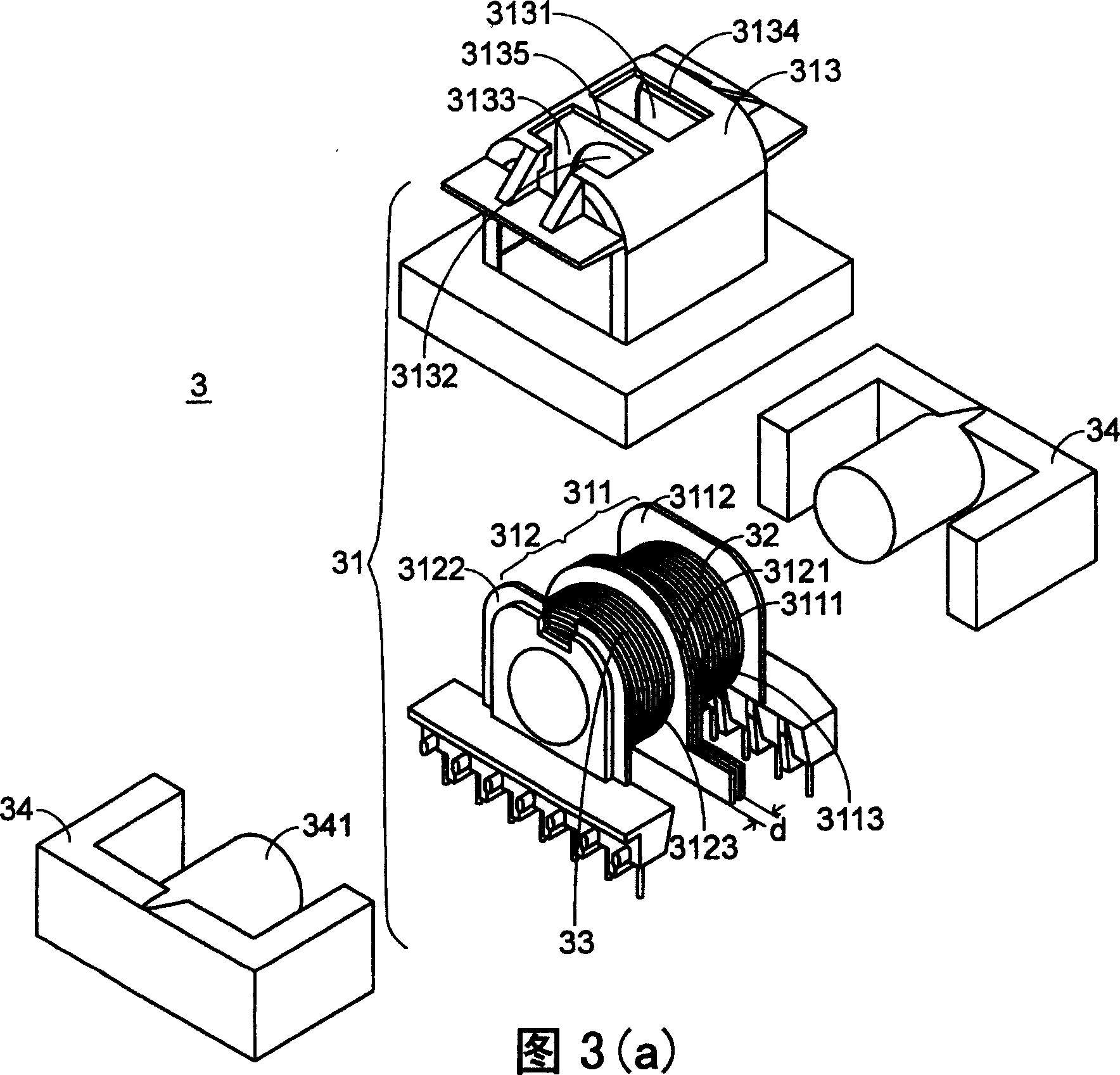

[0052] Please refer to FIG. 3( a ), which is a structural schematic diagram of a preferred embodiment of a transformer with leakage inductance in the present invention. As shown in FIG. 3( a ), the transformer 3 of the present invention includes a bobbin module 31 , a primary winding 32 , a secondary winding 33 and a core set 34 . Wherein, the winding frame module 31 has a first winding part 311 , a second winding part 312 and a winding frame cover 313 . The primary winding 32 and the secondary winding 33 are respectively wound on the first winding part 311 and the second winding part 312 . The iron core group 34 is EE type iron core (EE-core), EI type iron core (EI-core) or ER type iron core (ER-core). 34 generates electromagnetic coupling induction with the primary winding 32 and the secondary winding 33 to achieve the purpose of voltage conversion.

[0053] Please refer to Fig. 3 (a), the first winding part 311 and the second winding part 312 of the winding frame module 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com