Supercharger for double axle two stage turbine of supercharged diesel engine

A turbocharger and diesel engine technology, which is applied in the direction of machines/engines, mechanical equipment, combustion engines, etc., can solve problems such as the decrease of isentropic efficiency and the increase of blade end loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

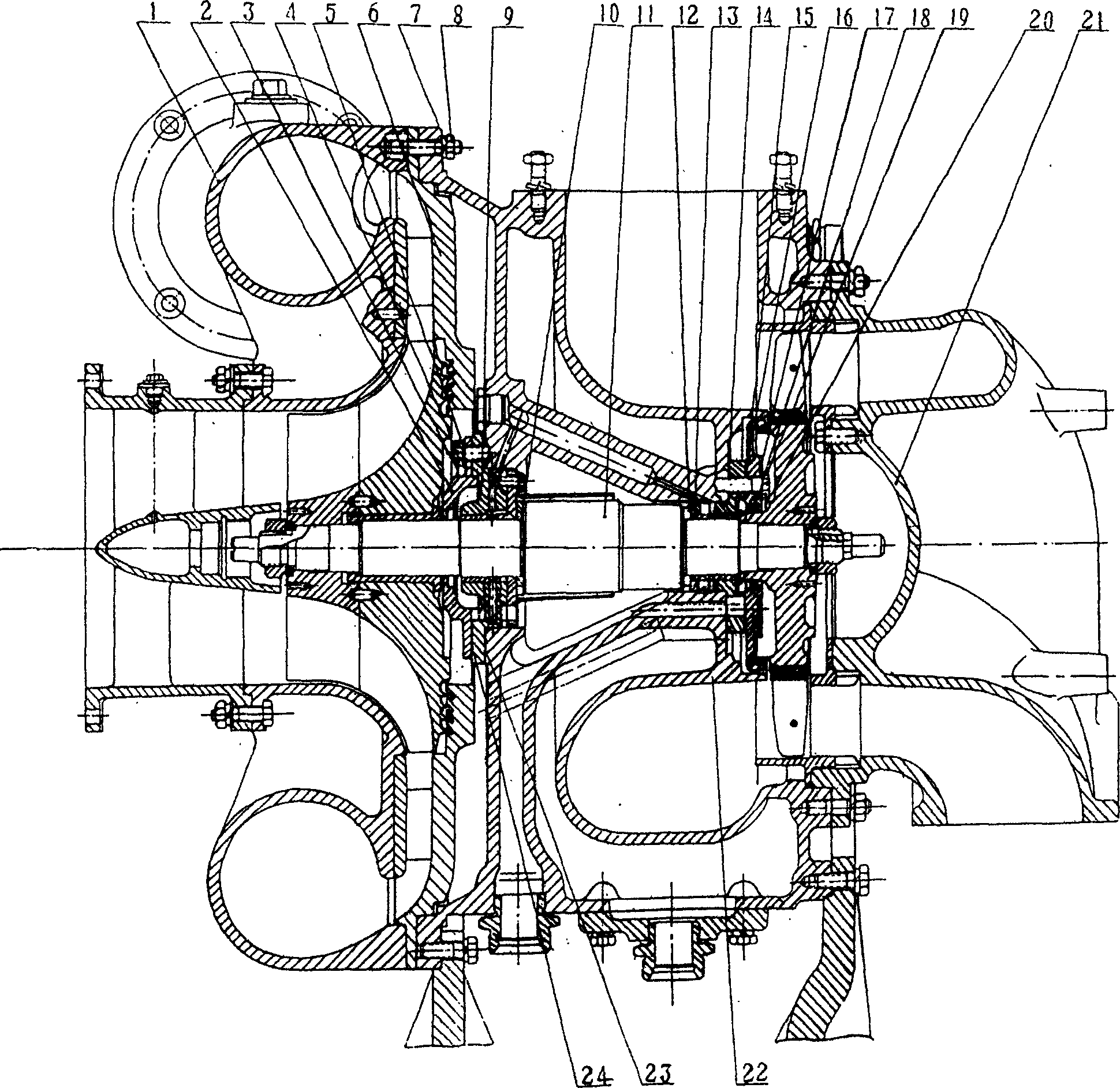

[0021] Figure 5 It is the schematic diagram of the twin-shaft two-stage turbocharger of the structure of the present invention, and its low, high-pressure stage turbocharger is respectively made up of the single-shaft axial-flow turbocharger and the single-shaft radial flow (or mixed flow) of the common structure of the prior art Type) turbocharger is composed of an axial diffuser tube connected in series between the outlet of the high-pressure stage turbine and the inlet of the low-pressure stage turbine.

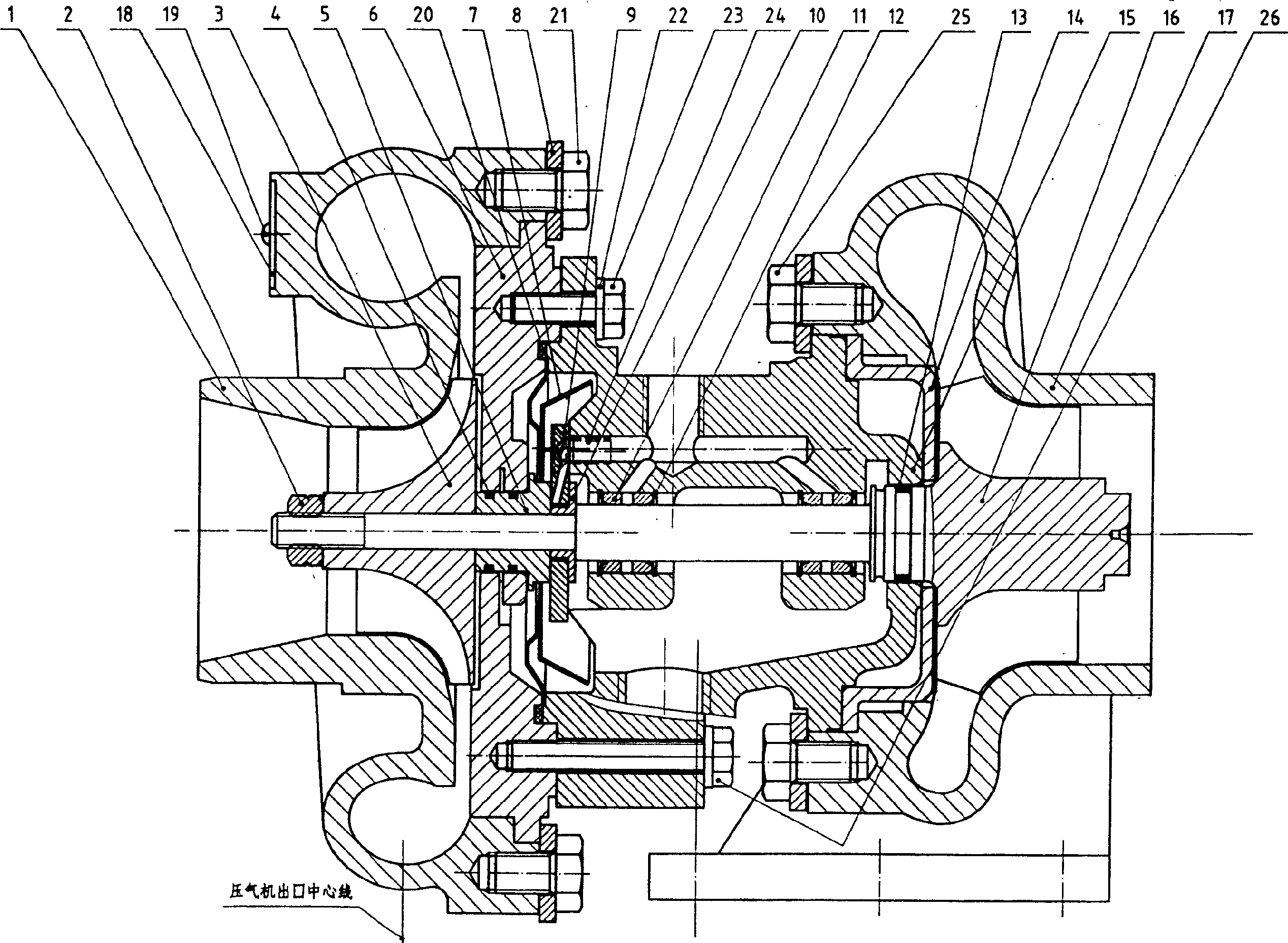

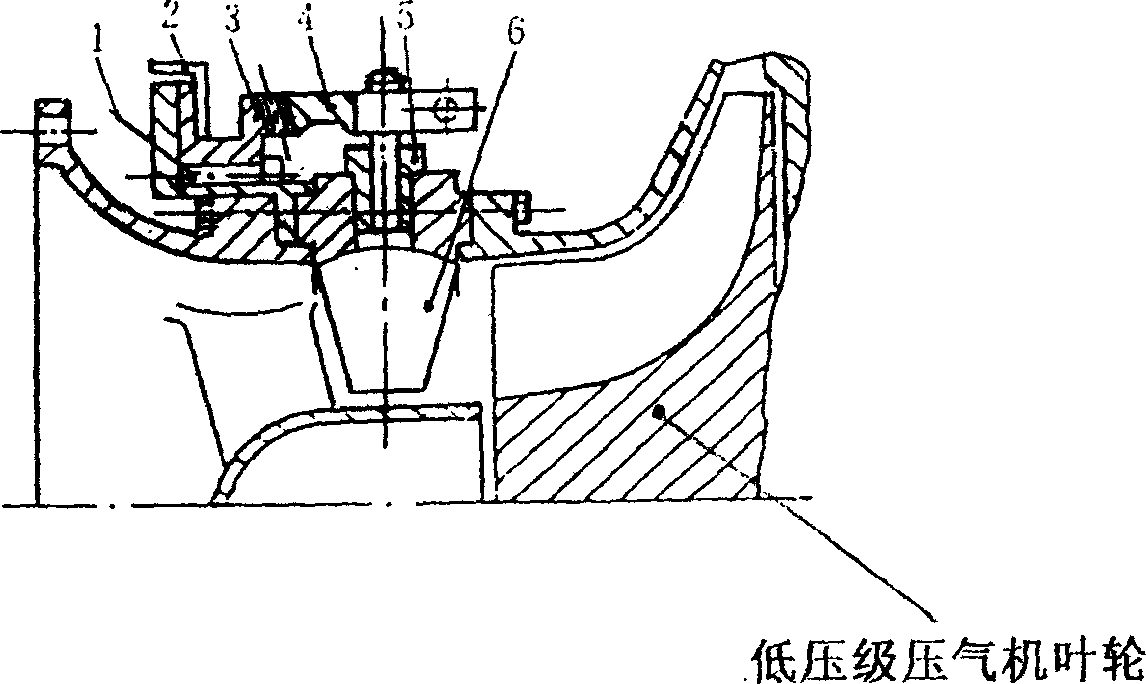

[0022] Figure 6 and Figure 5The basic structure is the same, but the inlet of the low-pressure stage compressor is installed image 3 The pre-swirl adjustment device shown has additional rectifying vanes in the diffuser.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com