Rotary electric motor having axially aligned stator poles and/or rotor poles

A rotary, electric technology applied in the direction of synchronous motors, motors, motors, etc. with stationary armatures and rotating magnets, which can solve the problem of not fully realizing the benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

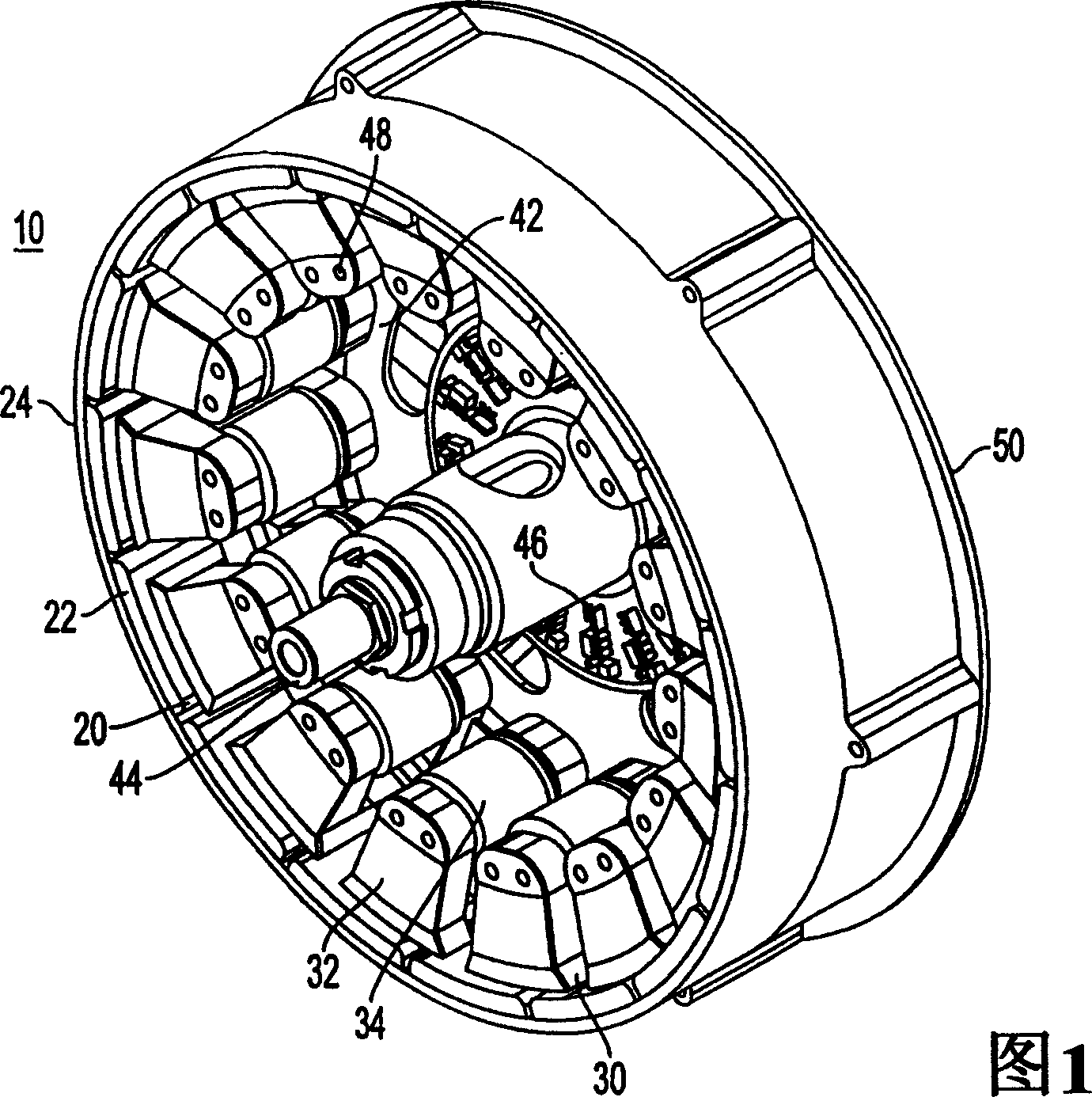

[0024] The motor of the present invention is suitable for use in driving wheels of automobiles, motorcycles, bicycles, and the like. Thus, the description of the drawings describes the structure of an electric machine that can be accommodated in a wheel, the stator being rigidly mounted on a fixed shaft and surrounded by a rotor for driving the wheel. It should be understood, however, that the vehicular situation is but one example of the many specific applications in which the electric machine of the present invention may be employed.

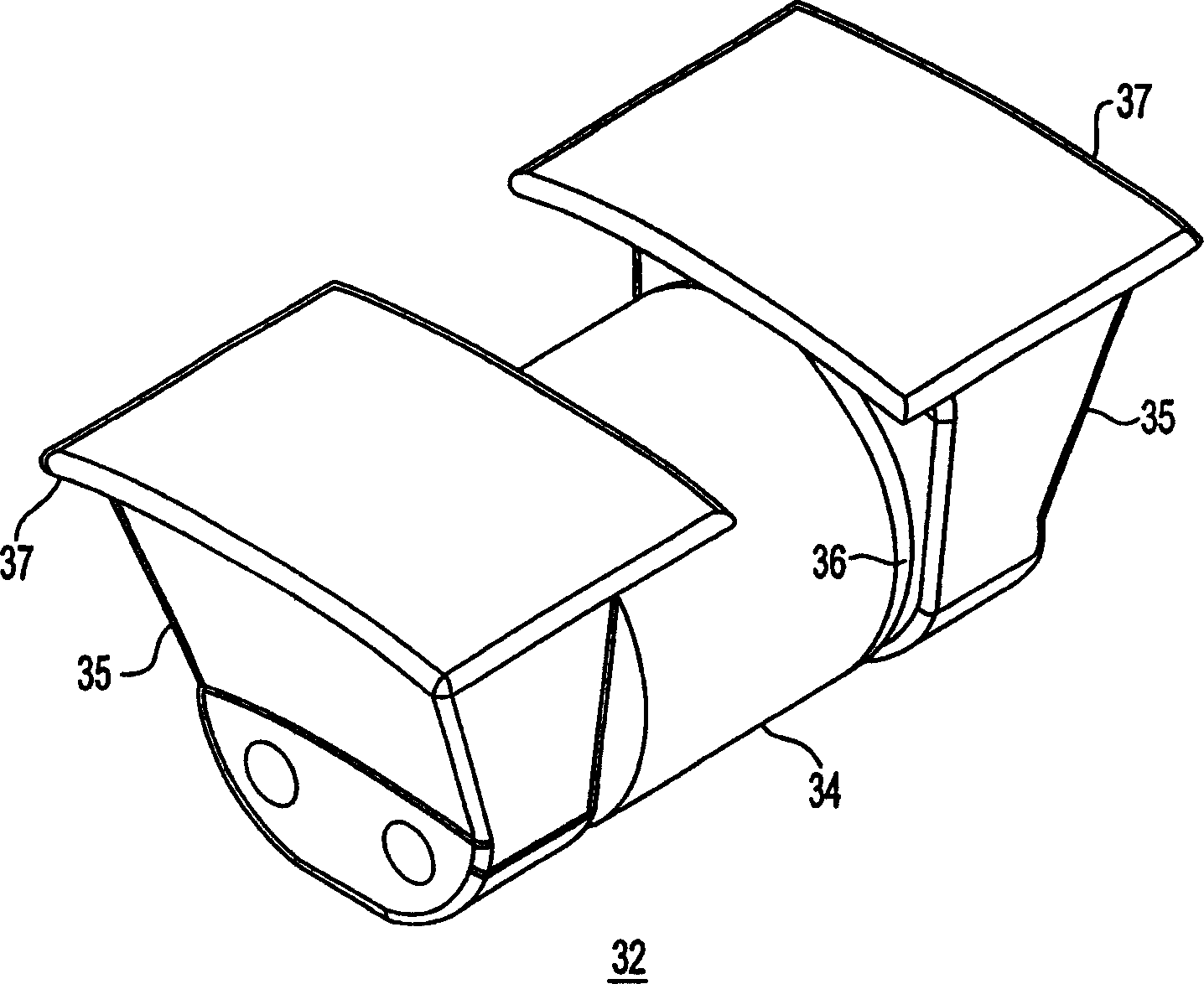

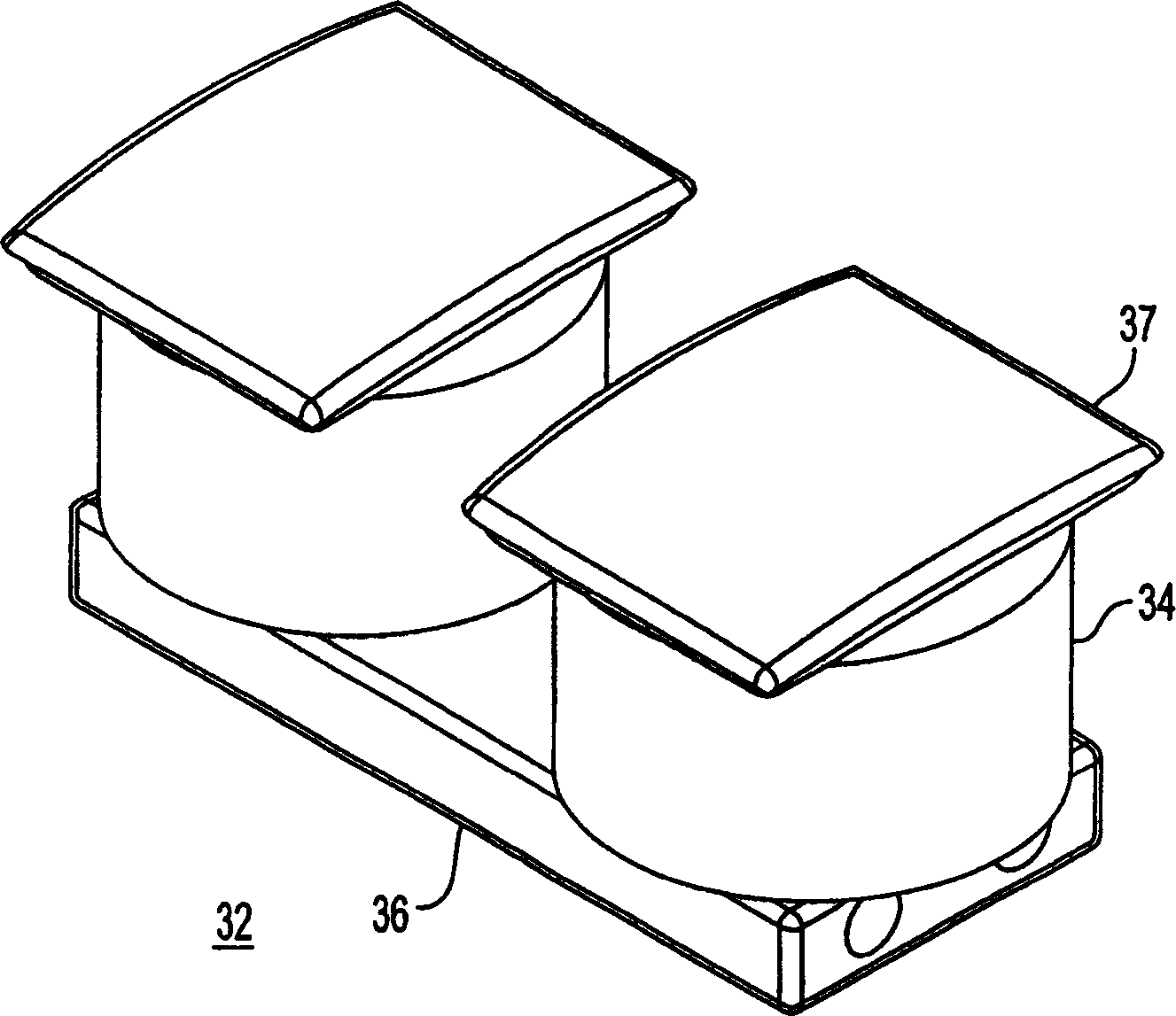

[0025] As shown in the cross-sectional view of FIG. 1 , the electric machine 10 includes an annular permanent magnet rotor 20 and an annular stator structure 30 separated by a radial air gap. The stator comprises a number of ferromagnetically isolated elements. Core segments 32 made of magnetically permeable material and isolated from each other from direct contact have respective windings 34 formed thereon. The rotor includes a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com